Greg Pendura, President and CEO, Mineworx Technologies Ltd. (TSXV: MWX, OTCQB: MWXRF, FSE: YRS, WKN: A2DSW3) Discusses Relocating their Pilot Plant to Johnson City, TN for Optimization Work for the Commercial Plant to Extract Palladium and Platinum from Diesel Catalytic Converters

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 12/14/2021

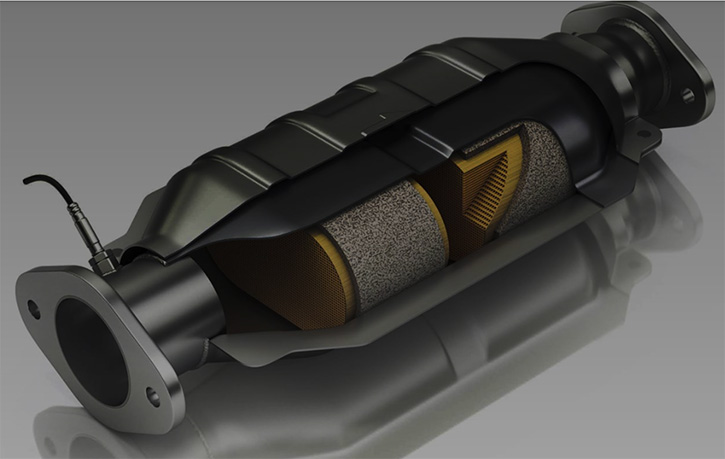

We spoke with Greg Pendura, President and CEO of Mineworx Technologies Ltd. (TSXV: MWX, OTCQB: MWXRF, FSE: YRS, WKN: A2DSW3), a Company that created a new proprietary processing technology, to extract palladium and platinum from diesel catalytic converters. The new proprietary processing technology, developed by Mineworx, presents a very efficient, economical, and environmentally friendly alternative to smelting. Since we last spoke in October, the Company relocated their pilot plant to their partner’s facility in Johnson City, Tennessee, Davis Recycling, for the final phase of the pre-optimization work for the commercial plant, which should be completed by the end of the second quarter of next year.

Mineworx Technologies Ltd.

Dr. Allen Alper: This is Dr. Allen Alper, Editor-in-Chief of Metals News, talking with Greg Pendura, President and CEO of Mineworx. Greg, since we talked last in October, you've accomplished a great deal, like getting your pilot plant ready. I wonder if you could tell us a little bit about what's going on with Mineworx.

Greg Pendura: Sure, Allen. Since we've spoken, the pilot plant has been relocated from Vancouver, where the initial testing was done. All the testing met our expectations. So, with that, we sent it down to our partners’ facility, Davis Recycling, in Johnson City, Tennessee. The pilot plant is adjacent to their facility, where pre-commercial test runs will begin, simply meaning that more throughputs will be performed in Tennessee. This Optimization Phase is where we'll begin to finalize our engineering and design for the commercial plant, which is anticipated to l be completed by the end of the second quarter of next year.

Dr. Allen Alper: That sounds excellent. Could you tell our readers/investors a little bit more about what you're doing there and why it's so important?

Greg Pendura: In Vancouver, we never had the opportunity to run the volume of throughput that we had to do in order to simulate commercial production runs Moving the plant down to Tennessee will accomplish this requirement. Simply by putting through more volume, it will give us the information we need for eliminating potential bottlenecks and improving production efficiencies for the commercial plant.

The optimization testing will begin before Christmas, and we expect it to run for approximately 30 days in order to have the data needed to complete the design stages for the commercial plant. The pilot plant, at that time, will then be used for ongoing optimization as we're completing the fabrication of the commercial plant.

Dr. Allen Alper: That sounds excellent. I understand the initial focus is the extraction of platinum and palladium from diesel catalytic converters, with your partner Davis Recycling.

Greg Pendura: Right. Davis Recycling is a large recycler in the Southeast US. He definitely is considered one of the larger recyclers. He has a great reach and not just in the Southeast. His network goes throughout the US. What Davis Recycling brings to us is expertise on the supply chain management side of the business. They've been in the business for well over 20 years and they have been very proficient in the whole aspect of supply chain management, all the way from procurement to quality control, to pricing to inventory controls. In this business, that is an extremely important function. We're very fortunate to be partnered with Davis Recycling, since they bring this expertise to the table, which greatly minimizes our risk, as a company going forward, because, with that part of it being taken care of, all that we have to do is the economic extraction and recovery of precious metals, which is our specialty.

Dr. Allen Alper: Well, that sounds excellent. The advantage of your process is that it is an environmentally friendly processing technology, for the recovery of precious metals, is that correct?

Greg Pendura: Yes, it is. And the reason we began with diesel catalytic converters is simply because of the market opportunity. We have an environmentally friendly solution to the extraction and recovery of platinum and palladium from spent diesel catalytic converters. The low hanging fruit in this area, is the fact that the only commercial processing alternative to recover these metals from catalytic converters is through smelters. There is no other commercial option available. And smelters, as of quite recently, have begun to refuse the acceptance of diesel catalytic converters in their system, because of processing issues that come about from the newer diesel catalytic converters.

Due to this, recyclers are no longer able to mix their gasoline catalytic converters with their diesel catalytic converters, as smelters are not allowing this any longer, or at a minimum, imposing penalties and restrictions on this practice. The end result is they are either going to be stockpiled in inventory or put into landfills. There is no optimum solution available right now. So, we are going to fit into a large market, which is growing year after year because of the increasing amount of diesel catalytic converters used, especially in the larger transportation vehicles. We're looking forward to being able to take care of this problem, in an environmentally friendly fashion.

Dr. Allen Alper: That sounds excellent! I understand too, your Company is looking into the development of its legacy iron ore concession further, which holds a hundred percent interest in Southeastern Spain.

Greg Pendura: We are. We have that project in our portfolio. We've done considerable work on it. In all likelihood, what we're trying to do here, Allen, in the next period of time, is to work on spinning that particular asset into a separate public company Once that happens, the intention will be to rebrand Mineworx as an ecofriendly precious metal, processing technology company along with a name change to better reflect this direction.

Dr. Allen Alper: Sounds excellent! Greg, could you summarize the primary reasons investors should consider investing in Mineworx Technologies Ltd?

Greg Pendura: Sure. I think from an investment perspective, Allen, we have quite an incredible opportunity here. We have a Company, with a market cap of approximately only $30 million right now. The market is basically waiting for proof of concept, of what we're doing in Tennessee in the pilot plant phase. And once this is completed and having this item checked off investors can look at a risk-free alternative to smelters, for the recovery of platinum and palladium from diesel catalytic converters. A company that will significantly reduce the environmental carbon footprint and bring exceptional monetary value to shareholders is exciting. From an investor perspective it’s a ground floor opportunity.

Dr. Allen Alper: That sounds excellent! Is there anything else you'd like to add, Greg?

Greg Pendura: We'll be having fairly consistent news flow coming out on the pilot plant testing and optimization. This will lead into the 10 tonne/day commercial plant fabrication and scale up. Shareholders will be continually updated on progress and our path to full commercialization.

Dr. Allen Alper: That sounds excellent! That will be great! It will be an exciting time for Mineworx Technologies’ shareholders and stakeholders.

Greg Pendura: We believe so! No question about it!

Dr. Allen Alper: Okay! That's great! We’ll publish your press releases as they come out so our readers/investors can follow your progress.

https://www.mineworx.net/

Greg Pendura

780-800-0726

greg@mineworx.net

|

|