Interview with Bernard Tourillon, Chairman and CEO of HPQ Silicon Resources Inc. (TSX-V: HPQ): Developing a New One Step Low Cost Process to Produce an Ultra-High Purity Silicon Metal Using its Proprietary PUREVAPTM Plasma Arc - Based Process

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 11/24/2016

Bernard Tourillon, Chairman and CEO of HPQ Silicon Resources Inc., TSX-V: HPQ, is excited

that HPQ Silicon Resources is successfully testing a new one step process to produce an

ultra-high purity silicon metal, using a plasma arc - based process. They are working

closely with PyroGenesis Canada Inc., a Montreal – based firm with 25 engineers, all highly

experienced with plasma arc systems. The result is a patent-pending process capable of

producing a high purity silicon product more efficiently than any other on the market. Mr.

Tourillon previously stated "By unifying this technology under our brand and successfully

scaling it up, we can accelerate our plan of becoming the cleanest, greenest and lowest cost

vertically integrated producer of Solar Grade Silicon Metal in the world. Thanks to our

great working relationship with PyroGenesis, combined with our ownership of the PUREVAP™ QVR

intellectual property, HPQ Silicon is uniquely positioned to become an agent of change in

the Solar Industry and beyond". Pierre Carabin, Director of Engineering of PyroGenesis

further stated: "We are very happy to be moving to the pilot scale with this process.

Throughout PyroGenesis' history, we have successfully taken new concepts from the lab to

commercialization. As we have done with the US Navy, developing the PAWDS technology from

lab scale to finally being specified in the design of the new US Aircraft Carriers, and more

recently, with our Drosrite technology. We plan to systematically and successfully ramp up

the PUREVAP™ process to full commercial scale. Once successful, we believe the PUREVAP™

process portends to be a game changing, and enabling, technology."

AA: This is Dr. Allen Alper, Editor-in-chief of Metals News, interviewing

Bernard J. Tourillon, chairman and CEO of HPQ Silicon Resources. Bernard, can you give our

readers an understanding of HPQ Silicon Resources' vision and what differentiates it from

other silicon manufacturers?

BT: Our objective is to become a vertically integrated producer of Solar Grade

high purity silicon metal, using our own sources of quartz – silicon dioxide - and our

process, PUREVAP™. What differentiates us is that we're testing a new one step process to

produce higher purity silicon metal as opposed to a traditional two-step smelting – refining

metallurgical process. We use a vacuum plasma arc process to reach our goal. The results to

date have exceeded all of our expectations and so we are very excited. Furthermore, we can

produce high purity silicon metal, using relatively low grade SiO2 feed material.

AA: That is very ambitious. Lets start at the beginning. How did your company,

HPQ Silicon Resources, end up in the high purity Silicon business?

BT: We had several mineral properties with quartz veins, some of which also had

gold in them. We were interested in looking into the possibility of extracting more value

from the rock than just the gold, which in some cases did not contain interesting grades.

AA: But quartz is a fairly low value commodity.

BT: You are correct. Raw quartz sells for about $50 per tonne. In my review of

potential applications for quartz, which is simply silicon dioxide, I was led to the world

of silicon metal. High purity silicon can sell for as much as $15,000 per tonne so the value

proposition was clear. This appeared much more interesting and higher value, so we secured

as many quartz properties in Quebec as we could and set about trying to figure out how we

could upgrade the quartz to high purity silicon metal.

AA: And this led you to Pyrogenesis? How did that come about?

BT: Yes it was rather fortunate, I had been investigating the opportunity, and

attending technology seminars with industry groups in Montreal, when I met the CEO of

Pyrogenesis, P. Peter Pascali. He was describing his plasma technology, which transforms

materials in the temperature range of over 3000oC, and the various applications and

contracts he has with the US military. I asked if he thought they could apply his

technology to producing high purity silicon from quartz. At the end of our conversation,

Peter said he would go away and discuss the concept with his team.

AA: That seems like a huge step, from initial discussion to where you are today.

BT: Yes well it took many discussions with the Pyrogenesis team of experts to

come up with a technical proposal, based on their experience with plasma arc, and also

understanding the quartz and silicon physical properties and, more importantly the

impurities they would need to remove. After many meetings they were able to convince

themselves that it could work, in theory. The next step was to build a device to run a first

test to see if it were possible. That took many months of work, which led to the successful

first test, conducted in Q2 2016. On that test they were able to produce a tiny drop of

silicon carbide, but more importantly, the test ran smoothly and demonstrated that what they

had theoretically estimated could in fact be accomplished – taking quartz and purifying it

in one step using the PUREVAPtm Quartz Reduction Reactor, (QRR).

AA: Bernard, perhaps you can explain a bit about silicon processing and how the

PUREVAPTM QRR system is different

BT: When I say very high purity silicon metal, I am talking about material with

a higher purity then 99.5% Silicon metal all the way to Solar Grade Silicon Metal, 99.9999%

Si or 6N.

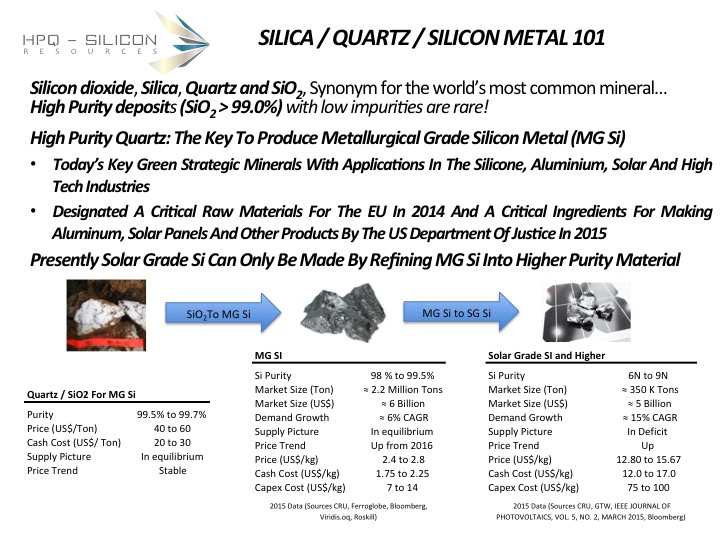

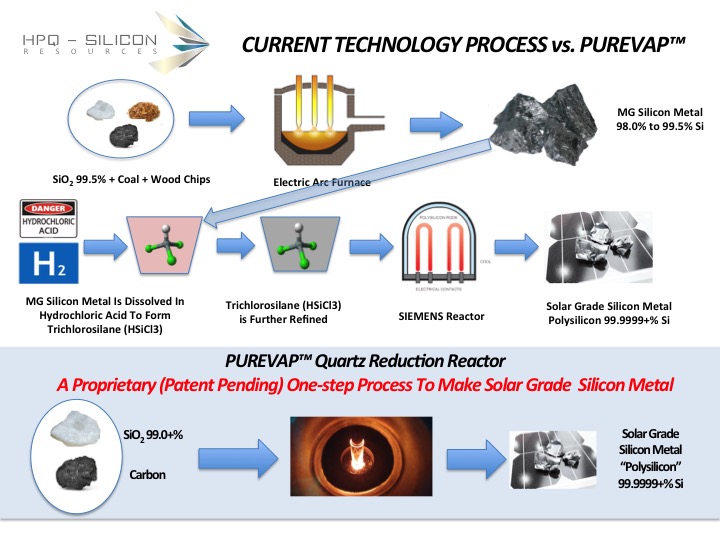

In the current processes, the first step to make silicon metal is transforming SiO2 into

metallurgical grade silicon metal, using traditional smelting technology. This processing

produces three levels of Metallurgical Grade Silicon metal: standard grade (98% Si), high

grade (98.5% Si) and chemical grade (99.5%). The highest purity that can be produced using

traditional smelting process is Chemical Grade (99.5% Si) and the process is very sensitive

to feed grade purity of the SiO2. The market for metallurgical grade silicon is about 2.2

million tonnes per year, representing about a $6 billion a year market, or about USD$3000

per tonne.

Production of Solar Grade Silicon is done through intense chemical and electro-refining of

Metallurgical Grade silicon Metal of 98.5% Si Purity. The Solar Grade Silicon produced from

the refining process is 99.9999% Si, the 6N mentioned previously, and has strict limits for

impurities. The market for solar grade silicon metal is currently about 350 K tonnes per

year, representing about a $5 Billion a year market, or about USD $14,000 per tonne.

With the PUREVAPTM process, we believe we will be able to reach 6N purity, during our

ongoing testing program, in one step directly from quartz. It's very, very promising.

In the last year we've advanced from the preliminary concept to proving that we can produce

better than Metallurgical grade silicon metal in one step.

Now we're in the process of developing ultra-high purity silicon metal.

We have one program, scaling up the process, while we're doing more R&D to reach 6N purity.

One doesn’t slow the other. Once we perfect creation of the 6N material, it will be the same

system we're building that will be expanded for the Pilot Plant.

AA: Well they were busy on the technology side, what kept you busy?

BT: I was very impressed by what Pyrogenesis had achieved in other applications,

and we were convinced the process would work, so we set about talking to investors to inject

some capital and negotiating an agreement with Pyrogenesis. During 2015 we negotiated a

definitive agreement to work together, however our potential investors found the

relationship confusing. So once we had completed the first successful test and knew this

would go forward, we decided to make a more formalized business agreement in which

Pyrogenesis and alter the relationship somewhat.

AA: What changed in the relationship?

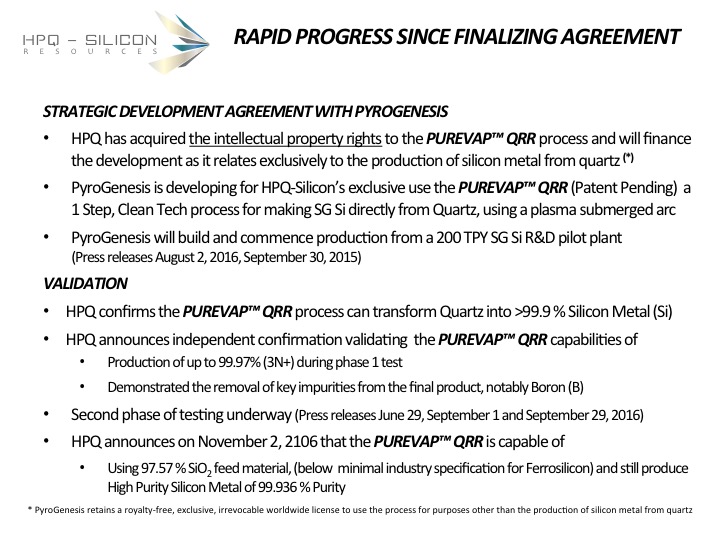

BT: We have always had an excellent working relationship with Pyrogenesis, and

continue to have one, but we needed to alter the business relationship to satisfy HPQ

investors that we were not at risk regarding ownership of the production of high purity

silicon. So we agreed with Pyrogenesis that HPQ would purchase the Intellectual Property

pertaining to production of high purity silicon, finance the Pilot Plant to production, and

ultimately contract them to build the production facilities. They would retain a carried

interest in revenue, but HPQ would own the facilities. It is a win – win – win for our

shareholders, Pyrogenesis, and HPQ Silicon. Our big advantage is that in effect, we've been

able to outsource, in certain areas, our R&D to PyroGenesis and by doing so; we eliminate a

lot of the risk associated with development. PyroGenesis is an R&D firm tailored to taking

laboratory scale projects and scaling them up. They only accept research projects that they

know they will be able to scale up. That's one thing that completely differentiates us.

That strategic alliance with Pyrogenesis gives us a tremendous advantage on the development

side and gives them a great advantage on the market side. If there are any issues in the

process and scaling it up PyroGenesis has 25 engineers that have worked with plasma arc

systems for the last 20 years. Whenever they encounter challenges, they have a massive pool

of knowledge and experience to resolve them.

AA: Tell us how the testing has gone so far.

BT: Our Phase 1 testing program, completed during the summer, allowed us to

achieve almost 4N material purity and, more importantly, we now have the data necessary to

implement the pathway to higher purity levels, right up to Solar Grade Silicon Metal. We

are especially pleased with the fact the PUREVAPtm QRR produced 99.97% purity material in

Phase 1 testing, as well as impressing us with its’ significant removal of impurities.

AA: And what work is underway now?

BT: Our ongoing Phase 2 program is validating the potential of the PUREVAPtm

QRR, as we have just announced that, very importantly, we have produced over 99.9% purity

silicon in one step starting with feed grade of 97.5% SiO2, which is lower than minimal

industry requirements, using traditional processes and we produced Silicon Metal (Si) of

greater purity than what can be achieved by traditional processes used to make Metallurgical

Grade Silicon Metal (98.5% to 99.5% Si) today.

AA: This sounds very interesting! Tell us about your near term and longer term

plans.

BT: The current focus is reaching Solar Grade Silicon Metal purity at lab scale

and validating that the process can be scaled up to commercial production. The work has so

far exceeded our expectations in every step so we are confident of achieving the purity

levels we are targeting, but of course we need to be sure we can do this economically. Our

long-term goal would be the construction of two production facilities of 10,000 tonnes per

year (tpa) of high purity silicon metal, producing around 20,000 tonnes of silicon metal in

the next five to seven years. Once we have perfected the Pilot Plant stage, we will decide

if we go straight to full production, or build a 2,000 tpa plant, then expand using cash

flow generated from that stage. It will depend upon economics, and the state of the capital

markets at the time. We will always want to maintain maximum financial flexibility for our

shareholders.

AA: That sounds like quite an achievement at $15,000 per tonne, what are the

milestones in 2017?

BT: So far we have produced droplets of silicon and silicon carbide. As I

mentioned earlier we have confirmed our ability to take lower grade feed material and purify

it in one step. Pyrogenesis is focused right now on increasing the size of the product it

can make, up to golf ball size, which is a major incremental step. That requires several

modifications to the process and the amount of time the feed is subjected to high

temperatures, among other considerations. All of this is what Pyrogenesis has done before in

different applications, so they are taking what they are experts in and applying the

incredible brain trust inside the company to solve these process issues. Once they scale up,

they will focus on getting to the very high purity of six nines. Our timetable now with

PyroGenesis is that the design and build up, the scaled up system, is anywhere between 12

and 16 months. That's saying, the Pilot Plant will be assembled at Pyrogenesis’ facilities

in Montreal. In the projects, we've already budgeted and accounted for are cold

commissioning, hot commissioning and then at least a period of ten months where they're

going to be running the plant at their facilities, making sure it's able to perfect and

repeat the process, being able to produce materials for 7 days, 24 hours a day. That's our

goal for the Pilot Plant.

In parallel to the Pilot Plant work, we have changed our approach on the resource

development based on the success of the bench test work so far and believe that we can

develop the quartz resources in parallel during 2017. To that end we just raised some flow–

through funds that will be allocated to drilling up and confirming the resource potential at

our Roncevaux Quartz property. By accelerating the resource development we will also qualify

for additional government support, and this effort will put us in a position to accelerate

the steps to production. So between the bench test work, Pilot Plant construction and

testing, and resource development, 2017 will be a big year for HPQ and Pyrogenesis’

shareholders.

AA: After the pilot plant is totally successful, how long should it take to get

into production? What CapEx do you need and what is the timetable for that phase?

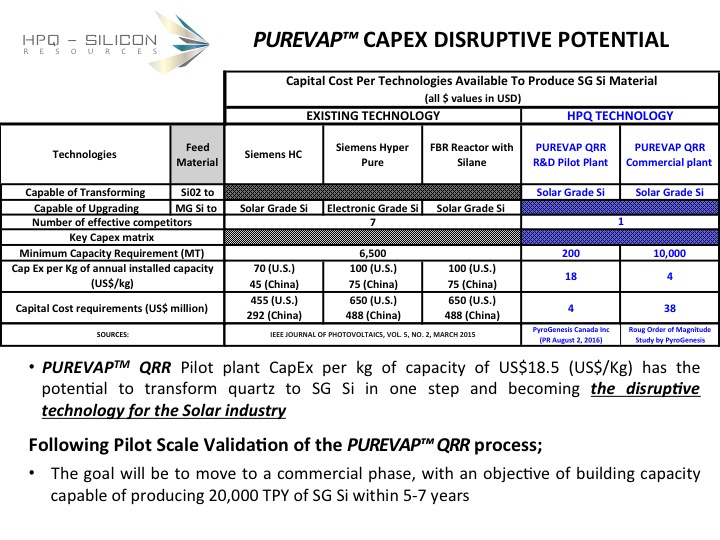

BT: We plan to go from the 200 tonnes per year pilot plant to either a 2,000

tonnes per year first commercial plant and then scaling up, or directly to our goal, a

10,000 tonnes per year operation. We have concluded that 10,000 tonnes per year units are

the optimal commercial size. The rough order of magnitude costs for those systems is around

$50 million. After the pilot plant is totally successful, we would like to be able to

produce around 20,000 tonnes in the next five to seven years, at two separate facilities.

The advantage is the scalability and a reactor the size that can be installed in an

industrial park, so we can install our system much closer to the source, the quartz source.

Since one needs 3 tonnes of quartz to make 1 tonne of silicon metal, then you realize that

effectively we can reduce our overall costs by only having to ship 1 tonne of the finished

product and not move around 3 tonnes of the material to a centrally located massive plant.

We have all those advantages, which explains why we want to get our resource delineation

works advanced as soon as possible.

AA: So far they have achieved almost four nines purity, is six nines the

ultimate target?

BT: Six nines is the industry standard for the solar grade industry, but it also

depends on the types of impurities, so for example four or five nines with zero amounts of

some impurities may be acceptable and of high value for some applications, so we have a lot

to work with. We have produced a silicon carbide intermediate product and there is also a

market for that, so we look at it today that six nines is the ‘gold standard’ and any lesser

purities will be our by-product materials. So we are attending silicon conferences and

talking to other industry players and to potential downstream buyers to determine the

opportunities.

AA: The silicon metal industry is a multi billion dollar per year industry, but

not many people know that.

BT: Yes private industrial companies dominate the industry and there are almost

no public small cap companies anywhere in the world. We are the only ones that we know of

that are testing production of high purity silicon. Typical processing today involves

smelting to make an intermediate product of approximately 99% purity and this needs further

refining to make high purity, solar grade silicon. So it is a two-step process just like

smelting and refining to produce metals like copper or zinc. Our breakthrough concept with

Pyrogenesis is that we can start with lower grade material, and in one step produce high

purity solar grade silicon. That is our goal, and so far it looks positive. Our huge

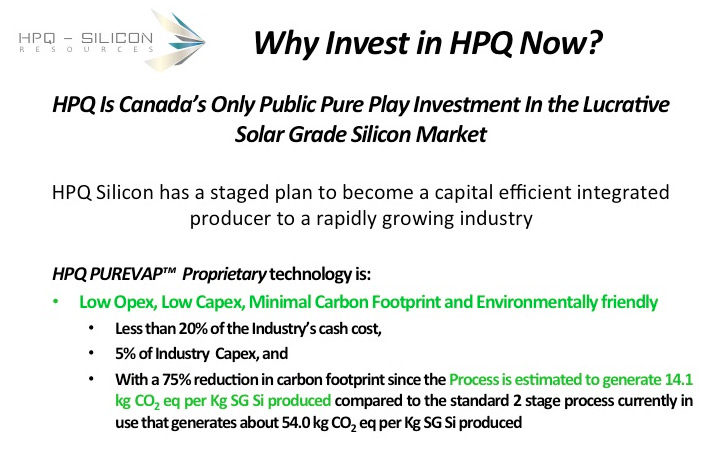

advantage is the one step process eliminates a huge amount of Capex and Opex. The following

chart demonstrates the comparison we have done in house between existing technology and the

potential of the QRR PUREVAPTM process.

AA: Sounds very energy intensive, tell us about the impact on the environment.

BT: Well there are two points to make. Our one step process will use much less

energy than the current two stage smelting and refining, but you are correct it is energy

intensive and that is why we have an advantage here in Quebec. In addition to the reduced

energy I would also add that the carbon footprint per tonne of silicon produced is

significantly less as well, so HPQ is not only looking at efficient ways but also a much

lower environmental impact compared to existing processes.

If you compare to the other ‘green metals’ like lithium and cobalt, the solar grade silicon

business is much larger and our one step QRR process is much greener, so investors looking

to invest in environmentally friendly companies should consider HPQ.

AA: How will you compete with the large players?

BT: In terms of competing, we see the solar grade silicon business as on the

cusp of growing very strongly, for example look at Africa. The attempts to build massive

hydroelectric power stations and transmission lines to electrify the continent have failed

to get started over the past ten years, and if they ever get going, will take generations to

complete. Individuals can get their own power to their own home in a matter of months by

purchasing solar panels at a much greatly reduced cost, and that is very compelling – and

transformative. Think of how cell phones jumped individuals in many countries past the

traditional fixed telephone line – it is the exact same concept. Also, as the existing

electricity infrastructure weakens and costs rise dramatically, such as in Ontario, Canada,

more and more people will look at the alternative of taking themselves at least partially,

‘off the grid’. We do not need to be in direct competition with the big players, we believe

the future market is large enough for many players.

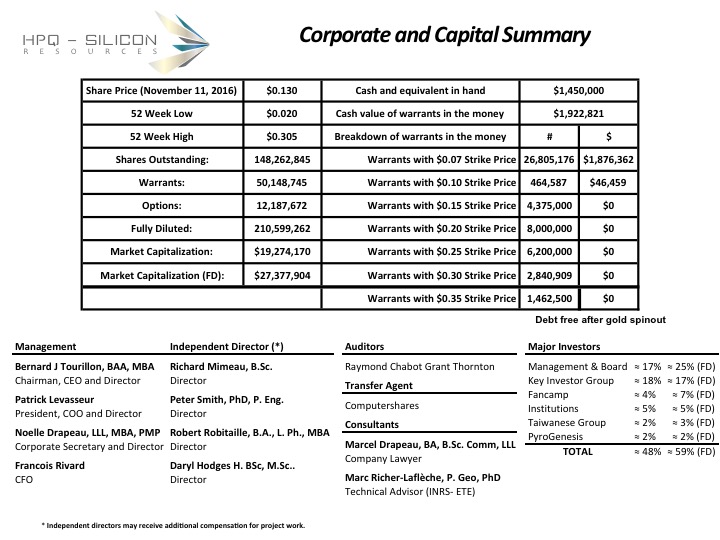

AA: I noticed your stock has had success over the last year, could you tell me

about your share structure and capital structure?

BT: Yes. Despite investor concerns about our ownership structure of the

Intellectual Property, the market did react very favorably to our Agreement with Pyrogenesis

a year ago. More recent pull back in the overall market and some inopportune large selling

has impacted our share price, but we will work through that. We have about 148 million

shares outstanding. Fully diluted we're at approximately 210 million. The share structure I

would say is about 17% directly controlled by management and board, and on a fully diluted

basis, our control of the company along with key investors is really closer to 60%. Small

institutional investors, and retail investors hold the rest. I'd say a mix of about 50/50.

What's really interesting is that we have about, between $2 and $3 million of warrants that

are in the money or close to being in the money, many controlled by management and key

investors. Furthermore, if all the warrants outstanding were exercised, the Corporation

cash position would increase by $7 million. It's a relatively tight float, but with enough

shares to get people interested. In addition to this, we are working diligently on spinning

out our gold asset into a new stand-alone company, which we hope to announce to the market

soon and have completed that by the end of the year. Shareholders of record will then have

shares in two companies.

AA: That's great. Could you tell me a bit about your background and Patrick's

background?

BT: Patrick’s and my background are similar and diverse. We both dabbled in the

financial market before moving on. I spent less time in it than Patrick did. My background

is mostly marketing, financing and manufacturing, before I moved into the junior resource

sector, where I've spent the last 25 years of my career. I've been in this business long

enough to have seen the ups and downs and everything in between. That's one of the main

reasons I like this project. We've been able to move away from the drill, drill, drill cycle

to mostly technology driven and improvement. So this is a case of new entrepreneurial

thinking entering a long standing business with fresh ideas and supported by technical

capabilities. In terms of specific technical and management expertise, we are still in the

‘entrepreneurial’ stage, but with great partners. As the company grows and evolves, we will

attract the right mix of young professionals to help us build this business.

AA: That sounds very well thought out for such an early stage. Could you tell me

the primary reasons our high-net-worth readers/investors should consider investing in your

company?

BT: I think it is rare that you have an opportunity to invest in a disruptive

process so early on. But we're much more advanced than people realize we are, because we've

kept very quiet. We have enough information to say that our process can potentially

generate very significant return to investors, so at this point there is a lot of Blue Sky

potential.

AA: That sounds very good. Is there anything else you'd like to add, Bernard?

BT: It's really going to be nimble companies like HPQ that can partner up with

the right technology partner like we did with PyroGenesis that will create the next leap

forward in mining and metallurgy, as we're doing. It's also going to meet the demand of the

general population and particularly, those who want a cleaner process, which we're offering

them. They want one with a smaller footprint on the earth, as we're doing. Everybody wants a

local component, where the resources are mined, and that’s something our system can offer.

We think this new way of doing it is going to be the way of the future.

The silicon market is as much a clean tech as lithium, but probably ten times larger than

the lithium market is right now, and it has the growth potential that is the same as

lithium. On the TSX Venture, we are the only silicon player talking about producing silicon.

We're the only one out there, as opposed to the lithium space where there are lots of

players.

AA: Well, that sounds very exciting. HPQ Resources Inc. trades under the ticker

HPQ.V on the Toronto Venture Exchange TSXV. We have been talking with Bernard Tourillon, the

Chief Executive Officer.

HPQ Silicon Resources Inc.

http://www.hpqsilicon.com/

3000 Omer-Lavallée, Suite 306, Montréal (Québec) Canada H1Y 3R8

Tel: 514 846 3271

Fax: 514 372 0066

Bernard Tourillon, CEO

bernard.tourillon@hpqsilicon.com

|

|