Dr. Derek Fisher Managing Director of Moly Mines Limited

We interviewed Derek Fisher, managing director of Moly Mines Limited, (ASX and TSX listed), at the Cambridge Vancouver Investment Conference. We are extremely impressed with the knowledge and background of Dr. Fisher and his team. He told us how the firm is focusing its efforts on the Spinifex Ridge molybdenum project in the Pilbara region of Western Australia.

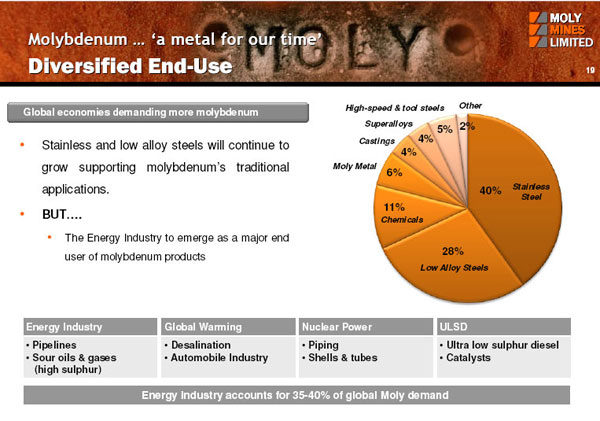

World molybdenum consumption has increased steadily from 250 million pounds in 1996 to 425 million pounds in 2006, and Moly Mines, of Western Australia, wants to be positioned to supply molybdenum to the steel industry when the economic recovery occurs.

Moly Mines management knows that molybdenum is becoming increasingly important to industry. This is not a surprise, considering its ability to improve corrosion resistance, strength, hardness and flexibility when it is alloyed with steel and cast iron. The worldwide search for new gas and oil reserves will also encourage demand for molybdenum, since extracting, transporting and refining oil and gas requires corrosion resistant molybdenum steels.

Dr. Fisher is as a geologist, a graduate of the University of New England, Armidale, NSW Australia. His first assignment was with Inco Ltd. in Australia, becoming a nickel expert and working in Canada. He continued his doctoral studies at University of Toronto, Canada, gaining his PhD in 1979. He returned to Australia in the early 1980s and is marking his 40th year in the metals industry. Dr Fisher is an honorary life member of the Association of Mining and Exploration Companies (AMEC), with 13 years on the AMEC council.

“I've been all over the world,” Dr. Fisher said. “I created my first company with some friends in the early '80s. That company was listed in Vancouver [Canada]. We built two gold mines with that company. At the same time, I created a company in Australia and turned that into a gold mine as well. Since then I've worked all over the world.”

Some of Dr. Fisher’s accomplishments include companies in Canada and Africa, as well as a copper mine in Mongolia. His was the first non-Russian, non-communist company to build in Mongolia in the 1990s. He also explored for gold in Siberia and Africa.

“A partner and I created Anvil Mining, and went into the Congo. I was also a seed-capitalist in Equinox, which is building a big copper operation in Zambia. So, I've been around.” Fisher said.

Establishing Moly Mines

When Moly Mines was created in 2004 it was a gold company. One of its gold properties had a bit of molybdenum on it. “I was probably the only Australian who had his eye on the moly price at the time, and I acquired Spinifex Ridge from the prospector who held it.”

When Moly Mines was created in 2004 it was a gold company. One of its gold properties had a bit of molybdenum on it. “I was probably the only Australian who had his eye on the moly price at the time, and I acquired Spinifex Ridge from the prospector who held it.”

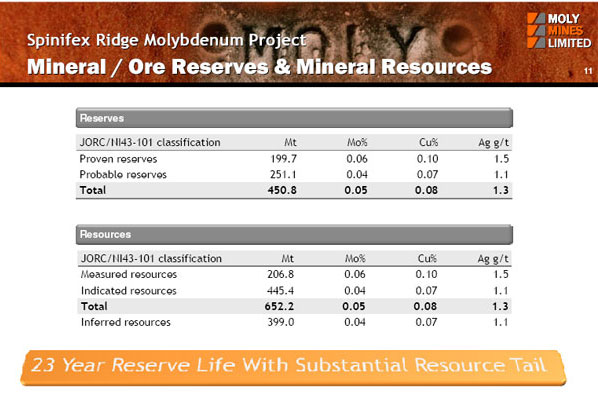

Spinifex Ridge is located in the Pilbara region of Western Australia. It has been defined at 20 million tons per annum. This is Moly Mines primary mining and processing operation, fully permitted and ready for development with a successful project financing. Dr. Fisher filled us in on the history of the project.

Spinifex was discovered by Anglo American in 1969 during exploration for copper. It drilled and walked away from it and Esso Minerals picked it up. They drilled 35,500-meter holes and identified it as a 150-million ton resource.

“That's what it was when we picked it up. We have subsequently spent about $150 million on it since 2005,” Fisher said. “We've drilled more than 200 additional holes, not only resource definition diamond holes, but also a lot of geotechnical and large diameter holes for metallurgical samples. We've completed a full, bankable feasibility study more than 18 months ago.”

“That's what it was when we picked it up. We have subsequently spent about $150 million on it since 2005,” Fisher said. “We've drilled more than 200 additional holes, not only resource definition diamond holes, but also a lot of geotechnical and large diameter holes for metallurgical samples. We've completed a full, bankable feasibility study more than 18 months ago.”

The feasibility study was based on a 20-million ton throughput mill, a mining operation, with a 1.1:1 strip ratio. The resource is 1.1 billion tons, at a cutoff grade at about 0.02 percent moly. “At today's moly price you need to increase that cutoff grade,” Fisher added.

Since completion of the feasibility study, Moly Mines has completed another 500,000 hours of detailed engineering, costing and dedicated work on the project to prepare it for construction.

Spinifex Ready to Go

Fisher points out that the project is fully permitted with all environmental permits and native title agreements in place. The mining leases and subsidiary licenses are granted and the pipeline corridors for gas and water are in place. “We could be on there building tomorrow if we had the cash,” Fisher said.

Spinifex Resource Area in Western Australia |

Access to the Ridge |

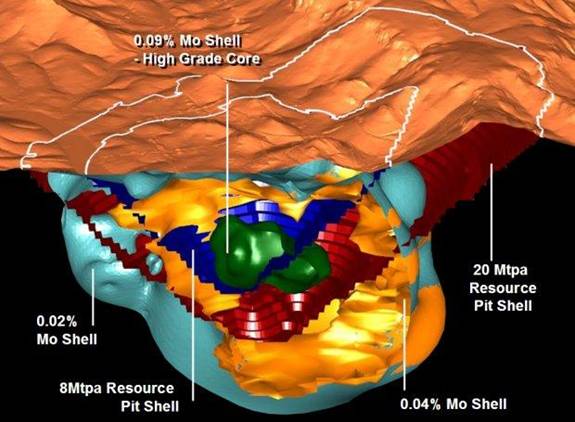

Fisher described the Spinifex ore body as having a high-grade core to it with grade that decreases as you go away in all directions. “We've redesigned the pit at a higher cutoff grade to accommodate a lower moly price, and we go down very quickly on that high grade. Strip ratio goes down. It's about 0.9:1, versus the old strip ratio of 1.1:1,” he said.

A lot of the material that is “waste” in this starter pit is mineralized but it is not financially viable to process it at today’s moly price. This will be stockpiled, and when prices improve and the mill is expanded, it will be put through the mill.

Though ready to start construction in September, the worsening credit crisis and economic situation halted Moly Mine’s plans, forcing them to layoff some of the senior technical management. The downturn in moly price in October and November 2008 exacerbated the situation.

“We've actually pulled back and laid them off because it's un-financeable; nothing's financeable today,” Fisher admitted. “But we have retained 30 high quality technical people who are dedicated to the project. We're not taking our eye off the prize, is really what I should say.”

An Innovative Start-Up Plan

One of Moly Mines’ options would be to start up in phases. Fisher told us that the original design for a 20 -million tonne per annum mill was two parallel circuits. Because of the large size of the mill it starts off with a single primary crusher, then two secondary crushers, then high pressure grinding rolls, then two ball mills and two parallel float circuits. A start up phase project would put a figurative line through the center and only build half of the processing line.

One of Moly Mines’ options would be to start up in phases. Fisher told us that the original design for a 20 -million tonne per annum mill was two parallel circuits. Because of the large size of the mill it starts off with a single primary crusher, then two secondary crushers, then high pressure grinding rolls, then two ball mills and two parallel float circuits. A start up phase project would put a figurative line through the center and only build half of the processing line.

In December 2008, Moly Mines had enough detailed engineering in hand to quickly do a feasibility study for this kind of start-up. The study could be completed by March or April 2009, which would give them a bankable document for the smaller-scale project.

The cost of the start-up proposal is estimated at well under half a billion dollars, according to Fisher. “The original mill was $1.1 billion. This option brought the cost down significantly.”

Strategic Alliance in Place

Another advantage is the firm’s roasting contract with Molymet out of Chile. Rather than build a roaster, they will produce concentrates of molybdenum and ship them to Chile for roasting. “Just licensing a roaster is a major exercise in Australia and in any country because you're producing sulfur dioxide. So, we've always had a tolling agreement and strategic alliance in place with Molymet, [the world’s largest independent processor of Molybdenum concentrates].”

John Graell Moore, Molymet’s CEO, suggested a concentrate of lower quality, at 42 percent, which would eliminate some of the cleanup phases within the mill. “Instead of having something like seven flotation phases we would have three. You produce a lower quality con. Your recovery is higher. You recover more moly because every time you clean it up you lose a bit of your moly, and your capital cost is lower,” Fisher explained.

With a significant portion of the staff working on the startup phase, Moly Mines negotiated US $150 million debt facility with TCW repayable at the end of October 2009. Part of that will pay for $90 million worth of long lead equipment for the mill ordered nearly two years ago from ThyssenKrupp in Germany. As well there is housing equipment for the construction camp. Some of that will be sold, as it is not needed immediately.

Spinifex Ridge is the world’s leading undeveloped primary molybdenum deposit and is ready for financing. All material development approvals have been received and manufacture of many of the major long lead items is complete.

Seeking Good Prices and Opportunities

What Fisher needs is a higher price for molybdenum. While it would be profitable at $10 a pound, that is not profitable enough for financing. “We need $15 to $17 to get the rate of return required to finance it. That's where we're aiming,” he said.

Spiniflex molybdenum resource model

“The next six months is going to be a pretty exciting period for us. We will be out there looking at opportunities with the support of TCW,” Fisher said. Given the right project, Moly Mines could be looking at companies producing any ferroalloy– tungsten, vanadium, nickel or chrome. “It's a great buying time at the moment, and we're looking for stressed situations,” he said.

Gaining a Worldwide Perspective

In late 2008, Fisher and his general manager, Mr. Collis Thorp spent time in China, Chile, North America, Germany, Hong Kong and London. “We talked to people on the supply side and the consumption side, just to get a very close understanding of where it all was, where the business was going. And we're strongly of the opinion that when it does come back it will come back reasonably quickly.”

“If you look at China, certainly the numbers we're seeing indicate that 40 percent of the moly mines in China closed in the last six months. So China's massive closure of moly mines is quite important. You go to Chile; you’ll see a 26 percent of drop in Codelco's moly production last year. Their grades are dropping,” Fisher added.

Fisher sees low copper price as having a major influence on moly production, citing a termination of Phelps [Dodge] development plans for copper mines. Additional evidence is in Canada, where Thompson Creek stopped development.

“I think when the infrastructure programs start to kick in around the world – and who knows when that's going to happen – we’ll see the market coming back,” Fisher said. “China announced they're doubling their rail line manufacturing capacity in 2009. So, again, that tells me that once it comes back, it will come back with a bang.”