Nautilus is developing and utilizing existing technology from the oil and gas industry to develop the seafloor minerals industry. There are huge mineral resources on the sea floor. Developing the technology to harvest these resources is a challenging task, and Nautilus is up to the challenge with mining, offshore drilling and finance professionals in key positions.

Known as seafloor massive sulfide deposits, these modern underwater furnaces continuously spew forth hydrothermal ooze composed not only of trace elements, but more importantly, zinc, lead, silver, copper and gold. In an era where the demand for these elements is increasing at a fever pitch, outpacing a dwindling and limited supply, it would seem only logical to turn to an opportunity that has been welling up underfoot for billions of years, right?

“We’re looking to change the face of the mining industry,” stated Anthony O’Sullivan, chief operating officer of Nautilus during a recent interview with Metalsnews.com.

With a current market value of $300 million, Nautilus is taking its groundbreaking venture very, very seriously. To fulfill its vision, the company has enlisted the support of three major international resource shareholders — Teck Resources at 6.8 percent, Anglo American at 11.1 percent, and Metalloinvest, Russia’s fastest-growing mining consortium, at 21 percent through Gazmetall Holding (Cyprus) Limited.

The second part of the Nautilus strategy is to “create option value within the space by taking out a large ground position at our southwest Pacific locale which we’ve targeted geologically and politically to undertake these operations,” according to O’Sullivan. This is to the tune of approximately 520,000 square kilometers of mineral parcel; for scale reference, that’s one and a half times the size of California, or twice that of the United Kingdom!

The third and last part of the Toronto-based junior’s grand design for its brilliantly futuristic endeavor is to demonstrate that they have the intellectual brawn to find and appraise these systems, although it seems they already have.

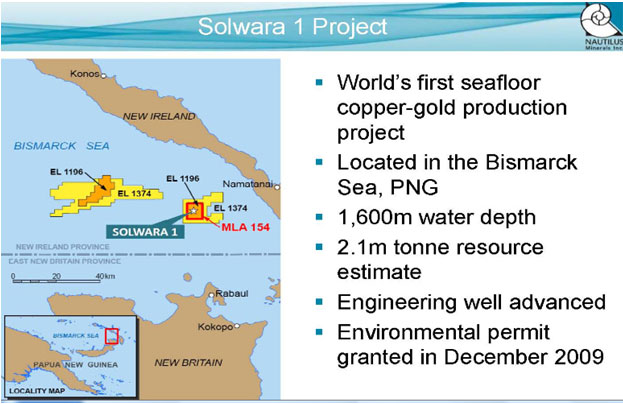

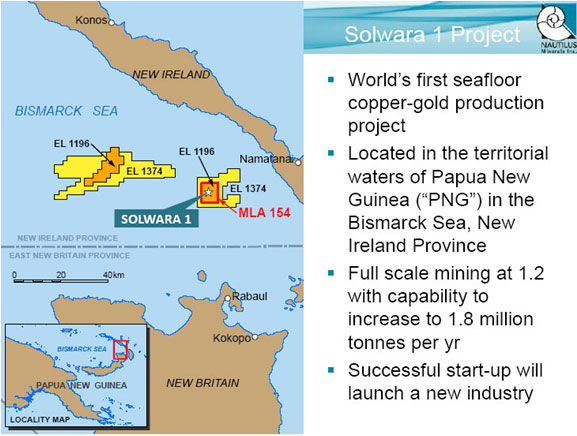

“To date we’ve identified 16 systems in Tonga, 19 in Papua New Guinea and evaluated one in detail, our flagship SOLWARA 1,” O’Sullivan explained. Drilling commenced November 1st and already 116 holes have been dug.

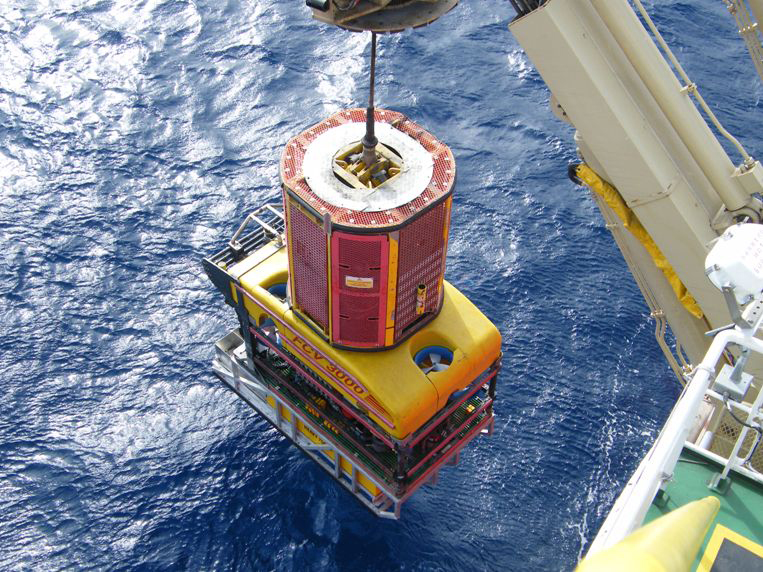

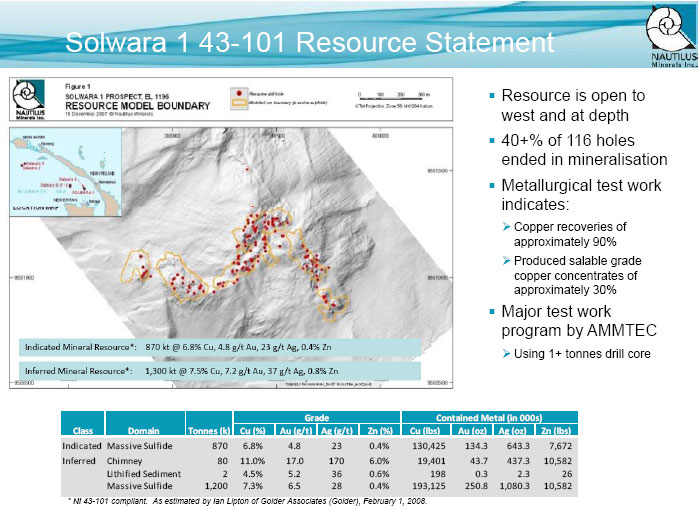

The 43-101 compliant resource deposit Nautilus is currently advancing is the result of following up the work of Chinese, U.S., French, and German scientific marine research groups that made the initial discovery of mineralization through studies to understand how underwater deposits formed. Of course, it couldn’t have happened on Nautilus’ end either without a team of highly specialized and experienced directors and management. It was this same team, employing existing surface mining technologies and combining them with newly developed offshore technologies, such as Remotely Operated Vehicles (ROVs), that put Nautilus in the forefront of exploration companies as the first in the world to produce a Seafloor Massive Sulfide resource statement.

Launching ROV

As issued December 20, 2007:

• Indicated Mineral Resource: 870 kt @ 6.8% Cu, 4.8 g/t Au, 23 g/t Ag, 0.4% Zn.

• Inferred Mineral Resource: 1,300 kt @ 7.5% Cu, 7.2 g/t Au, 37 g/t Ag, 0.8% Zn.

SOLWARA 1 is positioned approximately 30 kilometers from the coast of the

New Ireland Province and 50 kilometers north of the international Port of Rabaul. According to the company’s vast and impressive website, “Nautilus Minerals is developing an integrated production plan to develop a ‘best practice’ ecologically sound and sustainable recovery system for the known resource and expected resource upside.

The implementation plan is a two-phased project development:

• Development and demonstration of the offshore recovery system (Phase 1)

•Subsequent optimization through development of a mineral treatment facility (Phase 2).

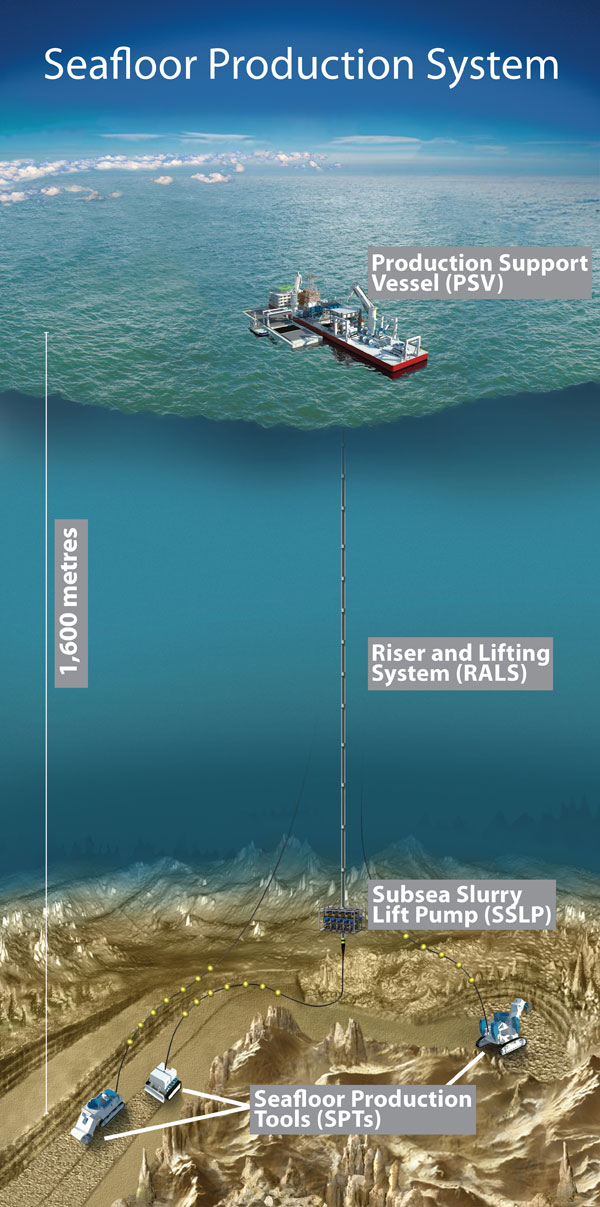

The Phase 1 operations are a pedigree of existing subsea and land-based mining technologies which beautifully complement each other, including: a sea floor mining tool, riser and lifting system, production support vessel, ore transfer barges and ore stockpile and handling facilities in the Port of Rabaul.

“Our development philosophy is to leverage off the technological developments that exist already in both industries,” O’Sullivan remarked.

Trenching machines already operate in the offshore oil industry burying pipes to minimize paraffin precipitation and ultimately to keep them out of harm’s way. The mining machines that will be deployed by Nautilus are an extension of this technology.

The orebody itself has shown that it has a hardness comparable to coal, and the system employed is similar to coal mining. A marinized drum cutter machine desegregates the ore and then another gathers it. DeBeers utilizes a machine similar in design to mine its diamonds.

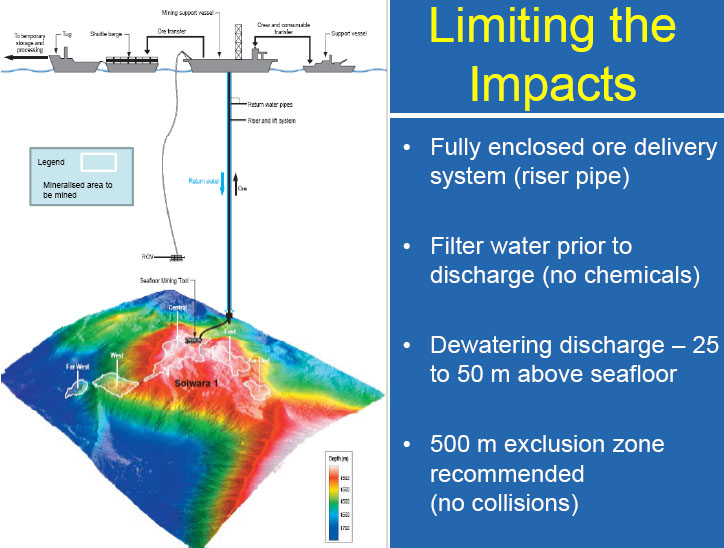

The closed loop pumping system, Nautilus uses to send up the material, is another brilliant feat in total compliance with the company’s environmental permit and commitment to minimize its impact on the ocean floor. The gatherer is connected to a pressure exchange device that pumps the slurry of about 12% solids by volume, to the surface. The water and solids are separated and dewatered using very conventional metallurgical technology screens, centrifuges, cyclones and filters. The return water is then pumped, at pressure, back down to the subsea pump pressure exchange device. The pressured return water provides the power to the slurry before being vented back onto the seafloor.

“It’s a very elegant engineering solution and also a very elegant environmental solution,” adds O’Sullivan.

For a company of this size to have all the resources it does, total transparency in its practices, and the potential to be in production in less than three years is more than just tremendous upside. It’s demonstrable ingenuity.

For more information, visit www.nautilusminerals.com