Interview with Don Mosher, President, Desert Mountain Energy Corp. (TSX.V: DME, U.S. OTC: DMEHF, Frankfurt: QM01): Building North America's First Vertically Integrated, Primary Producer of Helium

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 9/20/2022

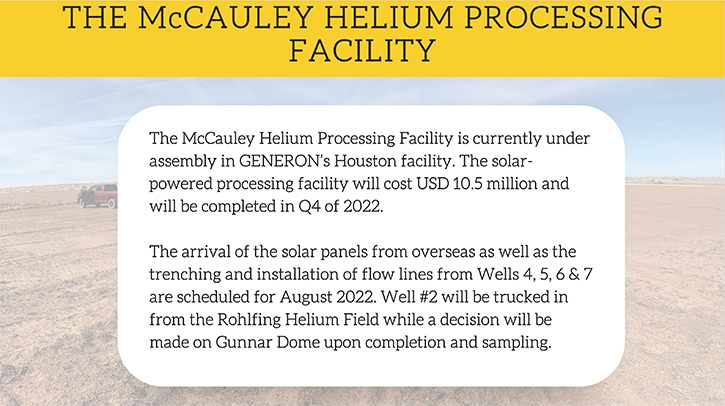

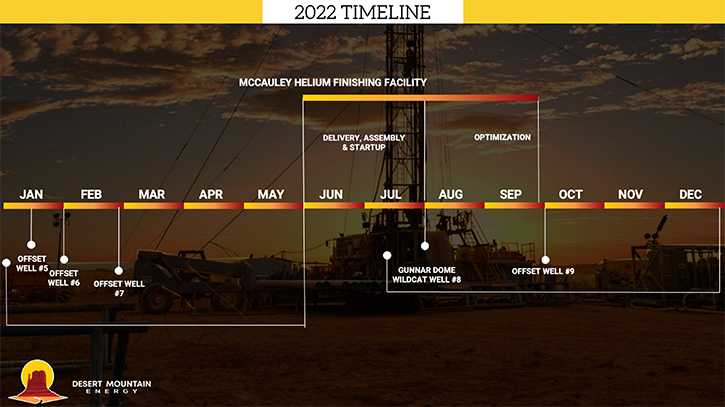

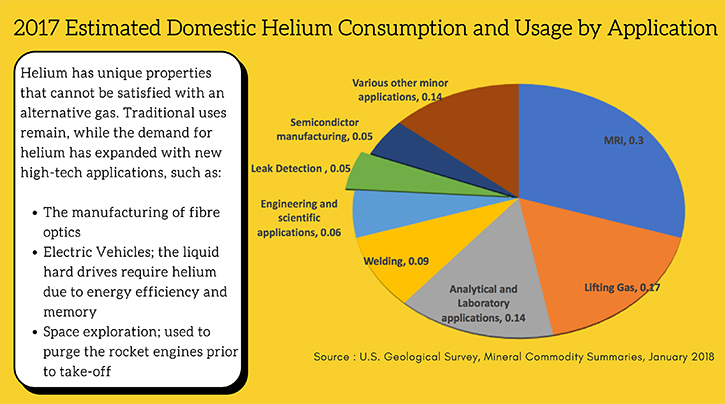

We spoke with Don Mosher, President, and Director of Desert Mountain Energy Corp. (TSX.V: DME, U.S. OTC: DMEHF, Frankfurt: QM01), a forward-looking resource company, actively engaged in the exploration and development of Helium and Noble Gas, at their wholly owned, district-scale Holbrook Project, in Arizona’s Holbrook Basin. Desert Mountain Energy is advancing the McCauley Helium Field, to initiate production, in Q4 2022. The Company signed the final contracts with GENRON for the construction of the McCauley Helium Field finishing facility, with all-in costs of approximately US $10,500,000. The Company plans to drill 7 offset and wildcat wells, in 2022. The Company has pre-ordered strategic components, for the Rohlfing Helium Field finishing facility. Helium is used in MRIs, in the manufacturing of fiber optics, in electric vehicles, and in space exploration to purge the rocket engines, prior to take-off.

Desert Mountain Energy Corp.

Dr. Allen Alper:

This is Dr. Allen Alper, Editor-in-Chief of Metals News, talking with Don Mosher, President, and Director of Desert Mountain Energy Corp. Don, please give our readers/investors an overview of your Company, tell us about the significant financing that you just received and its effect on the company and about the importance of helium.

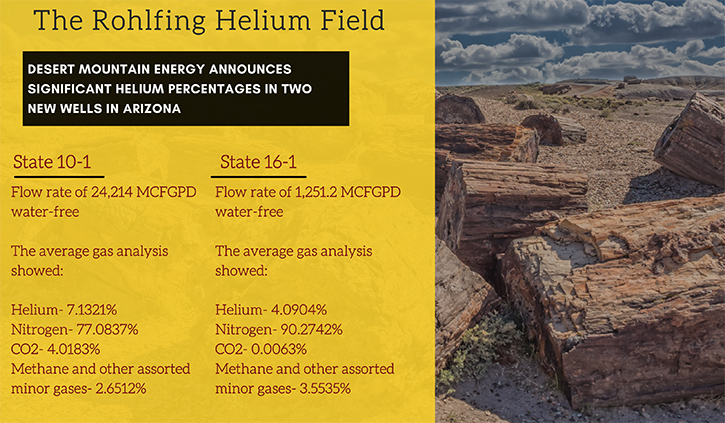

Don Mosher: Desert Mountain Energy has a project, located in northeastern Arizona, focused on helium. We're looking to build North America's first vertically integrated, primary producer of helium. We've successfully drilled eight helium wells, to date, with grades running anywhere from 1.137% to over 7%. Helium, which in the helium industry is extraordinary, because most helium comes out of natural gas fields at 0.3 to 0.7%. We have a Company, called GENRON, building us a processing facility that will be delivered to our McCauley Helium Field, sometime in early October, so it's getting pretty exciting.

Right now, we're seeing the assembly of the finishing facility, basically installed into four 40-foot storage containers that will be delivered to site and located on gravel foundations, that have been prepared. There are solar panels, sitting in the U.S., in storage right now, and they'll be delivered, once we complete the fencing, around the 10.6-acre plot that we're putting the facility on. Seven miles of trenching is currently being done and the flow lines from wells four, five, six and seven will run directly into the processing facility, from those wellheads.

In addition to that, we plan on trucking up some crude helium from, well number two on the Rohlfing Field. From well, number eight, which is the Gunnar Dome Wildcat that we're just completing. We feel that before the end of the year, we'll have achieved our goal of being a vertically integrated primary helium producer that is drilling their own wells, producing their own wells, finishing the helium and selling directly to end users in and around the Phenix area.

Dr. Allen Alper:

Well, that's fantastic. I must say, I'm kind of amazed at the rapid progress that you have made since we've been talking in the last few years. I think it's amazing how you're discovering wells, and you are building a processing facility. I think it's amazing the progress that you and your Team have made. You're all to be congratulated.

Don Mosher:

Thank you very much. This isn't an overnight project. People will take a look at it, and they track our progress, since we started drilling in July of 2020. Our CEO and Executive Chairman Rob Rohlfing, had spent 20 years studying the geology, walking this area of Arizona, and coming up with his own geological theories, as to why this high-grade helium exists in these nitrogen fields. The original field that was producing, back in the mid-60s, and mid-70s, was in a production facility, called the Pinto Dome. It had, I believe, the highest grades, from which anybody's ever produced. They ran 6% to 12% and production ran for about 12 or 13 years.

They shut it down because helium prices were only about $6.50 an MCF and they were using natural gas to process the helium. Natural gas prices went up and made the helium production uneconomic. So those fields would have produced for more time than they did, but unfortunately, they had become uneconomic.

It's a different scenario now. Number one, we're going to be running our facility on solar, backed up by hydrogen, out of our helium fields and the price of helium has tripled in the last four months, due to dramatic shortages that exist in the industry. They're shutting down MRIs, they're shutting down research laboratories, because they just can't find enough helium. The big suppliers have declared force majeure, on their clients, and they're lucky to be getting 60% of what they were promised in their contracts.

Dr. Allen Alper:

That's an amazing opportunity for your Company, shareholders and your stakeholders.

Don Mosher:

Yeah, well, we're very excited. When a company has a concept that they go to work on and in a couple of years, can bring it to fruition and achieve their plans and goals, it’s very satisfying. And we are so close right now, that we can taste it, literally.

Dr. Allen Alper:

Excellent times. Don, could you let our readers know the importance of helium, it’s uses and applications?

Don Mosher:

It's very much a modern high-tech gas. The largest users of helium are MRI machines, and unfortunately, they're shutting down MRIs because they can't get the helium to recharge them, as a coolant. In space launches, they use it to purge the rocket engines. Fiber optic manufacturers use it to create an environment, to be able to manufacture the fiber optics. Due to the nature of the gas, it's inert. If you have helium, they don't have to worry about it interfering or contaminating anything, during the process.

It's used in liquid hard drives. You can't have a Tesla, without a helium component, in those liquid hard drives. There are 17 hard drives in a Tesla, for example. There are all the traditional uses; welding, lifting gas, deep sea diving, leak detection. But its main purpose is as a coolant. It has the lowest boiling point of any element and if you're going to do research that involves trying to reach near absolute zero temperatures, you have to have helium. If you're cooling something, like a data center, you have to have helium. So, it really is all these modern applications, even these modular nuclear units, that Bill Gates has been funding, the research of those facilities, if they come online, will be cooled with helium.

The demand is increasing, and the production is decreasing because of the difficulties in getting permits for new pipelines and the lack of money that's gone into developing natural gas fields, which is where 95% of all helium comes from. We're unique. We are not in natural gas fields, and we do not need pipelines, so we don't need to go through the infrastructure, permitting, planning and all the studies that make it so expensive, and difficult to do. Especially if you're in hydrocarbons, whether you're an oil pipeline or a gas pipeline, you're facing a litany of challenges to get that through.

Dr. Allen Alper:

Well, that sounds excellent. It's really great that your facility is coming on stream. You're developing wells for helium and the timing is perfect and the need is so important. It sounds like everything is coming together.

Don Mosher:

We closed a $6 million financing, by issuing 2.3 million - $2.60 units after the market close on Tuesday. That really de-risks our Company and gives us a lot of financial security, while we achieve revenues. We're very pleased to have that funding come in. It allows Robb to stay aggressive and continue to pursue plans, to move this thing forward, quite quickly.

Dr. Allen Alper:

Well, that's excellent. Could you tell our readers/investors a little bit more about the McCauley Processing Plant?

Don Mosher:

When we're talking about a processing plant, we're not talking about a refinery. What we're talking about here is a facility that uses temperature and pressure swings and some membrane technology, to break out different elements, in a gas mix. Those elements are all mixed together in a soup, if you want to call it that. This facility pulls out the nitrogen and vents off the nitrogen, which is environmentally benign and works down to isolating the helium.

Then we finish the helium to, what they call a 6-9 purity, which is 99.9999% pure helium and sell it to end users that need those kinds of specifications. Obviously, lifting gas or balloon gas doesn't need to achieve those kinds of grades it's 80%, (99.95% helium) mixed with 20% filtered air, that's all it is. But when you start talking to semiconductor manufacturers, or space launches, or fiber optic manufacturing and MRIs, the purity levels have to achieve much higher standards.

Our facility will have the ability to produce either balloon grade helium, or achieve that 6-9 purity, gas standard. The throughput, on the facility itself, can run at a minimum 500,000 cubic feet a day, all the way up to 10.5 million cubic feet a day. So, it gives us a lot of flexibility on how much gas we can run through the facility. When we start up, we'll start out at about 500,000 and build it up to where we think the wells are operating, at their optimum flow rates, without endangering the well production, and at the same time allowing us to achieve profitability.

Dr. Allen Alper:

That's fantastic. What is the timing on the construction development of McCauley?

Don Mosher:

I think we'll be in the startup by the 1st of November. We expect to be receiving the modular housing units from GENRON, sometime in the next three weeks. The solar panels are in storage, they've landed from overseas. The fencing is going up next week. The trenching is being done right now. The plot itself, the 10.6 acres, that'll house the solar panels and the processing facility, that site has been prepared and leveled and gravel has been laid down on it. We're building it right now, and we'll probably have this whole thing built and turned on in the next six weeks.

Dr. Allen Alper:

Well, that's fantastic, really amazing.

Don Mosher:

I think that covers everything.

Dr. Allen Alper:

Okay. Great. We’ll publish your press releases as they come out, so our readers/investors can follow your progress.

https://www.desertmountainenergy.com/

Don Mosher, President & Director

(604) 617-5448

E-mail Don@desertmountainenergy.com

|

|