Greg Pendura, President and CEO, Mineworx Technologies Ltd. (TSXV: MWX, OTCQB: MWXRF, FSE: YRS, WKN: A2DSW3) Discusses Their Processing Technology and Recovering of PGMs from Feedstock, Initially on Diesel Catalytic Converters, and Their Completed Processing Plant, Sent to Johnson City, Tennessee, USA

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 5/2/2022

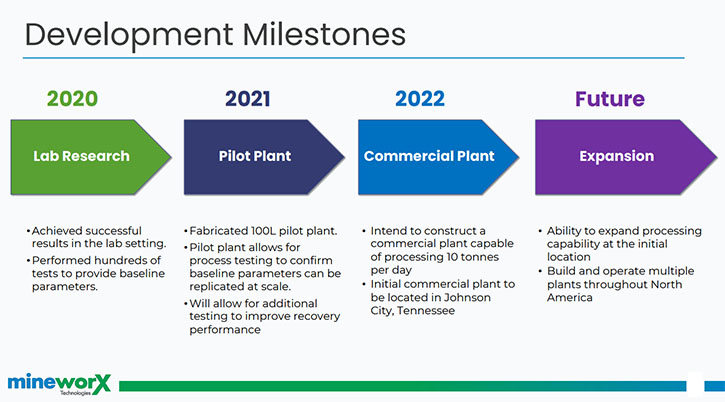

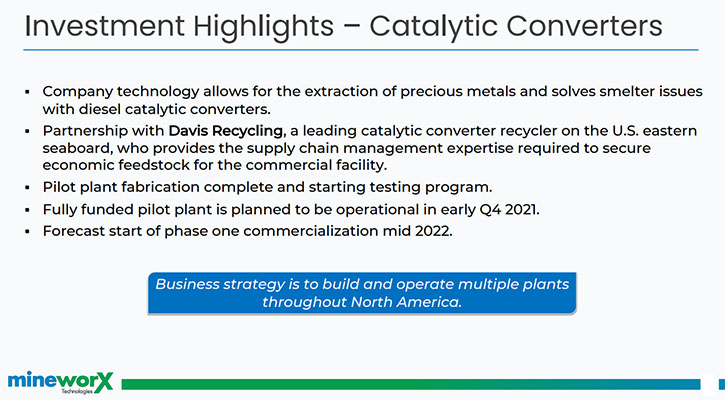

We spoke with Greg Pendura, President and CEO of Mineworx Technologies Ltd. (TSXV: MWX, OTCQB: MWXRF, FSE: YRS, WKN: A2DSW3), a Company that created a new environmentally friendly, proprietary processing technology, unlocking the massive opportunity, in the extraction of palladium and platinum from diesel catalytic converters. Mineworx has just announced the commencement of operations in its pilot plant, located in Johnson City, Tennessee, as all building and equipment permit approvals have been obtained. Next step is completing the design of the Commercial Plant and starting the preparation for the fabrication and construction of the facility. Initially, the plant will process 10 tons of the material, per day, generating revenues in excess of $100 million per year.

Dr. Allen Alper:

This is Dr. Allen Alper, Editor-in-Chief of Metals News, talking with Greg Pendura, who is President, CEO and Chairman of Mineworx Technologies. Greg, could you give our readers/investors an overview of your Company and also what's happening now and what your plans are?

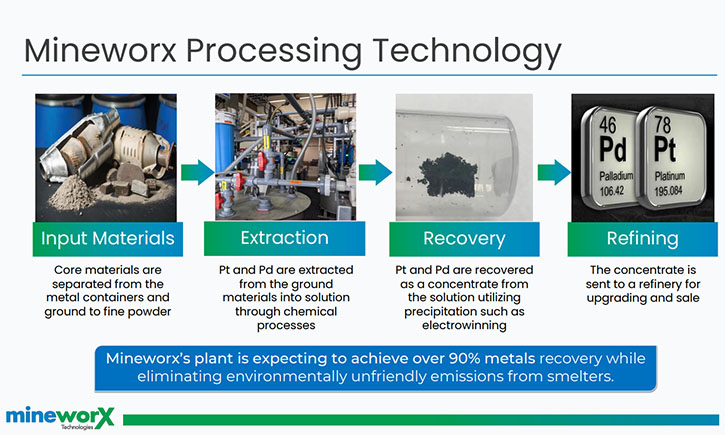

Greg Pendura: Mineworx Technologies is a metal processing technology Company, specializing in the recovery of PGMs from end-of-life catalytic converters. We've focused initially on diesel catalytic converters, due to a large, underserved, niche market, in which Smelters are avoiding due to processing issues. We have completed our pilot plant operations, in Vancouver, Canada, where the proof of concept, of our technology, has been confirmed. The plant has been relocated to Johnson City, Tennessee where it has been reassembled and is now ready to go through the process optimization stage, which will give us the information for the final design of our commercial plant. We've been waiting for approvals on various equipment and buildings permits, which have just been received, so we're ready to proceed and we'll begin operations immediately.

Dr. Allen Alper:

That sounds excellent! Could you give us more details on when you will actually start to recover elements? Also, tell us a little bit about how you collect the catalytic converters and process them. Could you tell us a little bit about that whole cycle?

Greg Pendura:

Sure. Up until a short time ago, diesel catalytic converters found a home with smelters. Smelters were the only commercially viable way of extracting and recovering platinum and palladium from the catalytic converters. With the advent of the newer catalytic converters, there are a lot of processing issues, beginning to be seen in smelters. So, they are beginning to refuse acceptance of silicon carbide-based materials. This is our tremendous opportunity.

Due to this, there's a stockpile of inventory adding up very quickly. There's a tremendous amount of value, within the catalytic converter market. It will be an annual $75 billion USD industry and only 30% of these PGMs are presently being recovered now, with the remainder going into landfills. We've developed a technology, which is going to solve this problem. We'll be able to extract the metals, as economically as smelters and in an environmentally friendly fashion.

We've already proven the concept, in our facility in Vancouver, with over 90% recoveries of platinum and palladium. What we're doing, in our plant in Tennessee, is simply ramping up speeds and processing a large variety of feedstocks, so we can better understand potential bottlenecks and inefficiencies, within a commercial operation. As I mentioned, this is going to give us the data, required to complete the commercial plant design.

Dr. Allen Alper:

Well, that sounds very good. Could you summarize the environmental advantages this process has compared to smelting?

Greg Pendura:

On the smelting side, people are well aware of the issues that smelters are having, with regulatory issues. There are obviously a lot of toxic emissions going into the environment, with their process. Our process is a chemical leaching process that basically ends up with inert materials. We won't have an environmental impact, either on air or wastewater, throughout our process. Our technology will fit, very nicely, into the clean tech space right now. We'll be catching the eye of the people, who are really concerned about the environmental side of things, and we're pretty excited about that. We see ourselves as playing a role in the carbon credit industry and receiving a secondary source of revenue from it.

Dr. Allen Alper:

That sounds excellent! Could you tell our readers/investors a little bit about your partner, Davis Recycling?

Greg Pendura:

Davis has been in the catalytic converter business for 25 years. They're one of the larger recyclers in the U.S., based in Johnson City, Tennessee. They focus on 13 states around their area, but their network goes beyond that. The reason why we wanted to align ourselves, with a professional, in the field, is because of their supply chain management expertise.

This is a very complicated business. Everything from initial procurement of the catalytic converters, to grading and pricing of the feedstock, to inventory control, to material preparation, for our processing technology, falls within their area of responsibility. If a company isn't well versed in this whole process, they're heading for a lot of trouble. Hence our relationship with Davis. They are going to give us that supply chain management expertise. All they have to do is continue carrying out their business, as they have done for the past 25 years, and all that we have to do is process the material, which they bring to us, and we'll have a very successful long term and profitable relationship.

Dr. Allen Alper:

That sounds like an excellent relationship and excellent partners! That's great! Could you tell us a little bit about your background and your Team?

Greg Pendura:

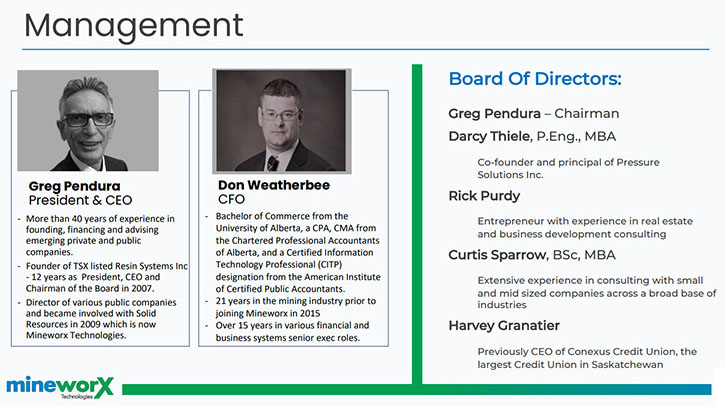

I've spent over 30 years in the public markets. I've founded a prior technology Company, many years ago, that developed a technology, based on a urethane-based chemistry, which we evolved into manufacturing composite transmission power poles, replacing steel transmission power poles. It's doing very well, at the present time. The poles are being distributed globally, so that endeavor worked out exceptionally well. After retiring from that endeavor, I've been on Boards of various mining companies. Mineworx has evolved, from a junior mining company, when I became involved 13 years ago, in a clean tech company, with global aspirations for becoming a player in precious metal recoveries, in the catalytic converter industry.

Don Weatherbee, our CFO, has over 20 years’ experience in the mining, heavy construction and material handling industries. His expertise, along with his many years of public market experience, will be extremely beneficial to our corporate development.

Dr. Allen Alper:

Well, that sounds great. Could you tell our readers/ investors a little more about your future expansion plans?

Greg Pendura:

The initial commercial plant will be designed for ten tons per day of material. Based on our initial pilot plant testing we anticipate revenues in excess of $100M USD per year, with attractive margins of around 20%. Our system is going to be modular in concept, so we can expand existing plants or expand to multiple locations, depending on business and market conditions.

Our initial focus will be on the U.S. and Canadian markets. After our first commercial plant is running in Tennessee, we will develop our growth strategies further.

Dr. Allen Alper:

That sounds excellent. Could you tell our readers/investors a little bit about your Research Director? What's his background?

Greg Pendura:

Fabricio Maia has been with us for about three years. He has a very strong background in the mining and metallurgical industries. He is the head of our R&D program and he's built a Team around himself, who has, in a matter of three years, gone from start up to pre commercial development. An accomplishment that is significant and the entire Team should be very proud.

To get to where we are, a tremendous amount of R&D has been done, from lab work, to pilot plant design, fabrication, and construction, to Process Optimization for commercial production. Our chemists and engineers continue to improve and optimize our system, both in Vancouver and in Tennessee, and I applaud their efforts.

Dr. Allen Alper:

Well, that's great. Could you tell our readers/investors, where your stock is listed and the symbols?

Greg Pendura:

Our stock, in Canada, is listed on the TSX Venture Exchange and our trading symbol is MWX. We have an OTC Q listing, in the U.S. and the stock symbol is MWXRF.

Dr. Allen Alper:

Greg, could you tell our readers/investors, the primary reasons they should consider investing in Mineworx?

Greg Pendura:

The major upside now is that all the hard work has been completed. From a risk scenario, most of the risk has been greatly reduced. Proof of Concept, of our technology, has already been established. we are now going down the path of commercial viability, which we intend to confirm very shortly. Our marketing efforts will begin to be increased, as we continue sharing our story to the business and investment communities. Increased exposure, in the media, is going to place us on the radar of many retail and institutional investors. I believe we have a story that is going to capture the attention of many, especially Green Fund participants, and as a result positively impact the valuation of our Company.

Dr. Allen Alper:

That’s excellent! Is there anything else you would like to add, Greg?

Greg Pendura:

As we confirm commercial viability, there is going to be a lot of excitement. To have a clean tech Company, with little competition, in a high dollar value market, with excellent economics, is going to attract a lot of attention.

Dr. Allen Alper:

That sounds excellent! That sounds like 2022 will be a very exciting time for Mineworx and for your shareholders and stakeholders. Sounds like a lot of hard work has been done, in setting the foundation, and a lot of the payoff will be coming in 2022 and beyond.

Greg Pendura:

No question, 2022 is going to be a breakout year for us. I believe, from an investment perspective, your readership needs to follow us.

Dr. Allen Alper:

That sounds excellent! We’ll publish your press releases, as they come out, so our readers/investors can follow your progress.

https://www.mineworx.net/

Greg Pendura

President & CEO

780 800-0726

greg@mineworx.net

|

|