Honeywell Providing Control, Automation, and Energy Optimization Solutions to Help Cobalt Blue Streamline Its Pioneering Broken Hill Cobalt Project (BHCP) to Ensure Rapid Scalability Between Pilot Plant, Demonstration Plant, and Commercial Operations

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 8/29/2021

We spoke with Joe Kaderavek, who is CEO of Cobalt Blue Holdings Limited (ASX: COB), and with Andrew Hird, who is Sales Director in the Pacific for Honeywell. Cobalt Blue, an Australian exploration and project development Company, advancing its large feasibility-stage, Broken Hill Cobalt Project (BHCP), in New South Wales. When in production, the BHCP will be a top-five ex-African producer of cobalt. Honeywell is a Fortune 100 technology company and industry leader, with a long history of mineral processing experience that will provide control, automation, and energy optimization solutions to help Cobalt Blue streamline risk management and development of its pioneering BHCP. Honeywell will utilize its expertise to ensure rapid scalability, between pilot plant, demonstration plant, and commercial operations. Cobalt is a strategic metal, in strong demand for new generation batteries, particularly lithium-ion batteries, now being widely used in clean energy systems.

Dr. Allen Alper: This is Dr. Allen Alper, Editor-in-Chief of Metals News, talking with Joe Kaderavek, who is CEO of Cobalt Blue Holdings Limited (ASX: COB), and with Andrew Hird, who is Sales Director in the Pacific for Honeywell, who is helping Cobalt Blue, in their projects in Australia. I'll start off and ask Joe Kaderavek, CEO of Cobalt Blue, to explain what Cobalt Blue is doing, set the stage, also where they're located and why their project is so important. So, Joe, could you tell us about that?

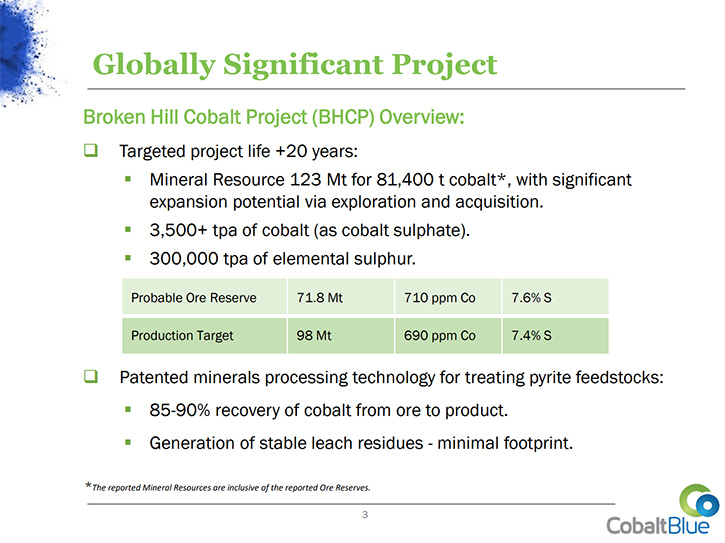

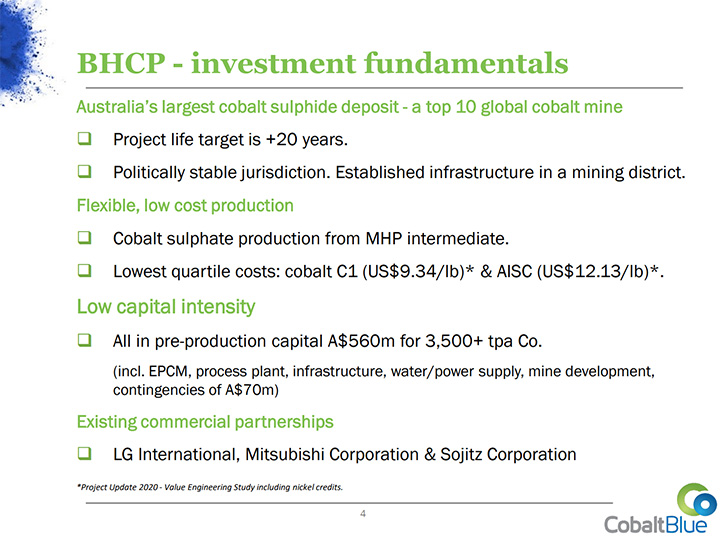

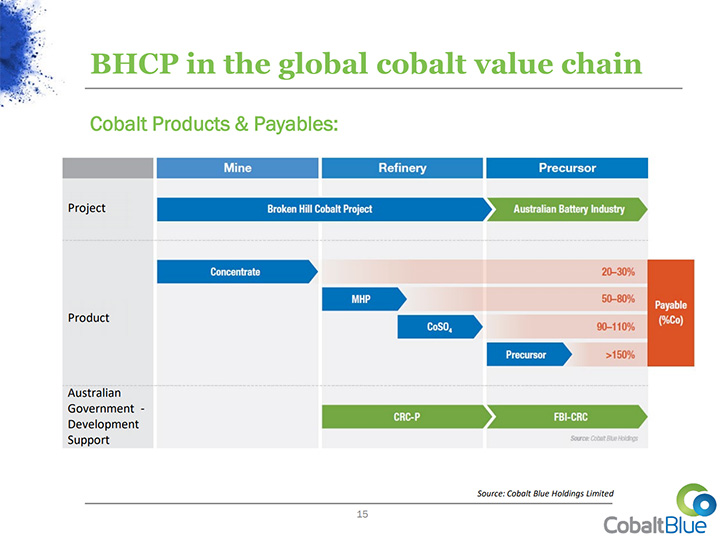

Joe Kaderavek: Thank you. Thank you for the opportunity to introduce the Company and our business. Cobalt Blue is an ASX-listed Company. We have our primary asset, the Broken Hill Cobalt Project. The Broken Hill Cobalt Project is a greenfield project, which we are currently developing and at the feasibility study stage. When in production, the Broken Hill Cobalt Project will be a top-five producer of cobalt ex-Africa globally. So, it's a very large project. The project will produce three and a half thousand tonnes of cobalt per annum, either as one of cobalt intermediate products, an MHP or a final cobalt battery-ready product, a cobalt sulfate. The Broken Hill Cobalt Project is Australian domiciled, so it's in a safe, stable jurisdiction. The business intends to have a chain of custody, series of initiatives around that, to ensure that the product meets the ethical sourcing standards for global producers.

In economic terms, it will be in the lowest quartile of cost producers globally. It has an extremely efficient processing plant. And that's where our Honeywell colleagues come in, to make sure those efficiencies and processes meet their particular targets. In terms of capital, amongst our global peers, it has a capital intensity of one-third to one quarter of any other comparable project, because we are a primary cobalt project. We're not a by-product cobalt mine, which is the case in 98% of all other producers. And as a result, we have a very small capital intensity, relative to our peer group.

So, in summary, it's an Australian-based project. It's very large. It's very long dated. It'll have a 20-year-plus operating life. It'll have the flexibility to switch, between an intermediate to a final battery-ready product and it'll have a very small capital footprint as well as a very low operating cost.

Dr. Allen Alper: Oh, that sounds excellent. It sounds like it's a critical program for supplying electric vehicles and for electrification of the world, so that sounds excellent. Maybe the Honeywell people could talk a little bit about their services and their technology, and how they're helping Cobalt Blue in their processing and manufacturing.

Andrew Hird: Sure. Hi, this is Andrew Hird. I'm the Sales Director, here in the Pacific, which is Australia, New Zealand, and Papua New Guinea, for Honeywell. It's our great pleasure to be working with Joe and the Team at Cobalt Blue on this critical project. I think the reason we're involved is we have a long history of mineral processing experience, both here and globally, with customers in the Illumina sector, the gold sector, et cetera.

So, what we're bringing to the party is, as Joe said, a relentless focus on project execution to reduce any risks. The technology that we've utilized, with many of our large global mineral processing customers, is designed to help with the scale-up of this project and with reducing the execution risk and cost, and then also post-project, in the implementation phase, to ensure that we can minimize any costs on operating the plant, by doing as much as we possibly can remotely. And that will help bring to bear the skill sets, right across Cobalt Blue, no matter where they are globally, to use those skills to run and optimize the mineral processing facility, this first project, and any future projects, upon which Cobalt Blue embarks.

So, connecting their people, their subject matter experts, with the folk at the mine and the mineral processing plant and plants, and also to connect with any key suppliers to Cobalt Blue, any process licenses, any equipment manufacturers – no matter where they are globally – we want to provide the infrastructure to help those people continually optimize and operate the mine, in the safest most productive mode possible. And that's brought to bear through a number of different technologies. So, in the design phase, using simulation and modeling to scale the plant up, as effectively as possible, and then to use those same models in the implementation of the project, when we build things like the safety system and the control system. So rather than two separate technologies, one for simulation and one for control, we use the same underlying models. As the plant moves into operation, using those same models, the same process and instrumentation diagrams, built as a digital twin, to continue to train the Cobalt Blue staff and to continue to optimize the plant through technologies, such as asset performance monitoring and advanced process control.

Dr. Allen Alper: Well, that sounds excellent, Joe. Could you tell our readers/investors a little bit about the timetable and the schedule, of moving where you are, to getting the plant into production?

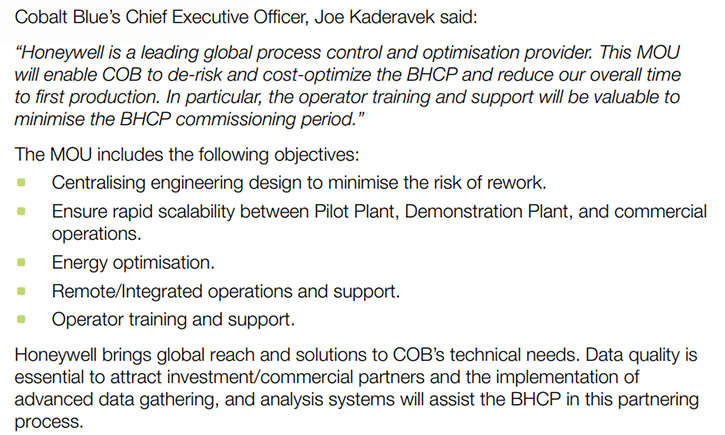

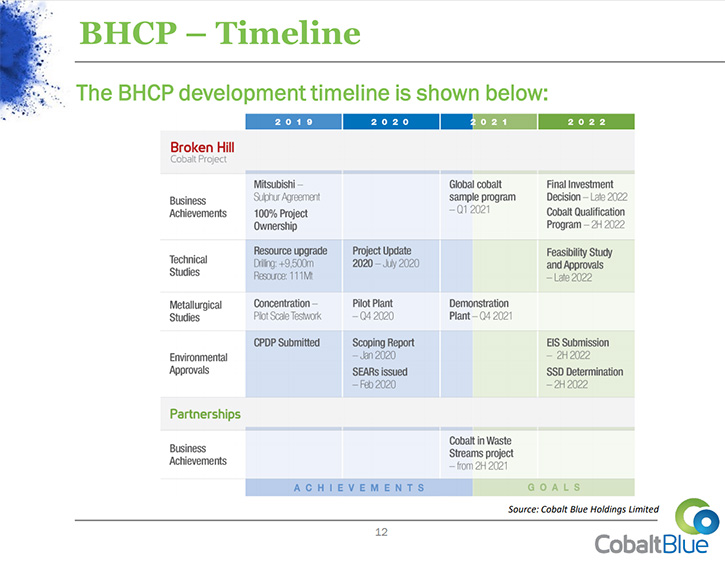

Joe Kaderavek: Thank you. We are currently executing a feasibility study. We use the JORC definition of a feasibility study, which is the equivalent of a bankable study. We're looking to deliver that in early 2023. In the interim, we'll be running our technical work programs, but also concentrating on a pilot, soon-to-be demonstration scale plant. And it's the confidence that those operations give us, it's the data set that's collected around those operations, with which our colleagues at Honeywell are helping us, that are critical.

We want to have the confidence to produce the product, but also ship samples of both the intermediate MHP and final sulfate products to partners. We're looking, therefore, to introduce the project into the global battery chain. And again, when you build a relationship in the mining sector with the downstream, you're really building a relationship based on the quality of the data. That's been apparent to us for some time. And this is where our relationship will bear fruit.

In parallel with the delivery of the feasibility study, we will be executing and finalizing environmental and approval programs for the project. Also, we'll be finalizing banking and financing packages. So, all roads lead to early 2023. Beyond that, we'll be commissioning a definitive engineering study. In other words, tightening up the accuracy and the cost estimates and getting into a contractor-ready series of documentation, and then we will begin the build phase. We estimate the build phase to be, depending on the part of the process, between 18 months up to two years. And we'll be beginning some of the necessary production phases, at the 18-month mark, with, we believe, a ramp-up of the full process at the two-year mark, which puts us in the 2025 category for first year of production.

Dr. Allen Alper: Well, that sounds excellent, Joe. Could you tell our readers/investors the primary reasons they should consider investing in Cobalt Blue?

Joe Kaderavek: Yes. Thank you. There are a number of elements to the investments, some of which are unique to us at Cobalt Blue. Firstly, we are 100% owners of the only primary cobalt project that's investible in the world. There are no other opportunities like this anywhere that are listed. Indeed, there's only one other mine in the world that'll give you exposure to cobalt that we offer, and that's the Kingdom of Morocco itself.

Our project itself is very large. It'll have a material impact on the global cobalt supply chain. It's very long-lived. So, it lends itself to strong commercial relationships. We're in the middle of building that now. It is in a safe and stable jurisdiction, which is very sought after from our partners. We also are custodians of an intellectual property, or proprietary process, which we've developed, in building the Broken Hill plant. We believe we can expand our footprint, from a single project, to a second or third project, as a result of that. We believe we're in the right place, at the right time, to feed the cobalt chain, particularly with a focus on batteries. So, the products that we're making will lend themselves or dovetail very comfortably into the global battery chain.

So, there are a number of reasons for us as a stock investment, but also in the backdrop, the cobalt market is tightening. There are, strong indications that cobalt will remain a core part of the cathode for the mass market vehicles in particular. And I think that we're going to get a very tight market in the next five to 10 years.

Dr. Allen Alper: Those sound like very compelling reasons, Joe, for our readers/investors to consider investing in Cobalt Blue. You have a huge resource, in a great location, a great team and great support, now from Honeywell, so that's excellent. I wonder if the Honeywell people could say a few words about why other companies should consider using their technology.

Andrew Hird: Sure. This is Andrew Hird with Honeywell here in Pacific. Firstly, on Cobalt Blue, I think another reason we're very excited to become involved in this project, is the green nature of the project. So, getting an environmentally stable and well-extracted cobalt resource into the supply chain, as Joe said, in a stable geography done right is very critical, because it works very closely with Honeywell's commitment to work in a sustainable way wherever possible. A green supply of cobalt is absolutely important for the world's supply of batteries, so firstly, we’re very excited to be involved with Cobalt Blue.

Secondly, I think the reason why globally significant players, in the mineral processing sector, come to Honeywell is because we have the technology to make this work. Implementing projects of this size is something we've done, around the world, with very large mineral processing companies. The technology is well-developed and a lot of it actually originates here, in Australia. We have a very large software center in Sydney, where the control system itself has been designed for over 20 years. That's a critical resource to help customers like Cobalt Blue and other major players implement projects, and help them along the way, by modifying where necessary, products to help optimize their processes. So that's on the control system side.

The optimization of these plants is critical once you've built them, keeping them operating at peak performance, getting the energy cost reductions that are so critical, getting the production improvements over time that are so critical and getting the yield right, so making sure there's a relentless focus on quality is really important. And that's where our software business comes in. We've been implementing software in the mineral processing sector, for many, many years, and that's with the largest global mineral processing companies that you see. Some of those are in Australia and others are in South Africa, but we've done large projects, focused on optimizing the energy production, cost and sustainability and yield of these projects for a long time.

So that's that unique technology, designed in Australia, implemented in Australia, the deep domain experience we have in mineral processing, plus the optimization technology. On top of that, plants like this, as Joe said, are going to be running for decades. And we've been in partnership, with our customers for decades, running these facilities. We invented the control system, in the 1970s, and we've been supporting those same technologies since the 1970s. So, I think those are a couple of key reasons mineral processing companies come to Honeywell. The second would be in digital transformation.

As large companies go, from traditional supply chain and traditional vendor relationships into transforming their businesses, both on the process side and also on the assets side, as they try to optimize their process and their asset availability and they optimize their supply chain, only Honeywell can do that. We have a very strong digital transformation practice that focuses on not just the process of asset optimization, but also the supply chain optimization and closing the loop on digital transformation, by getting work instructions right down to the operators.

Dr. Allen Alper: Well, those sound like extremely strong reasons for the mining companies, with which we deal, and other mining companies, to consider using your technology. You've been known for years and years as a totally reliable technology company and you are an outstanding company. Is there anything else that, Joe, you or Andrew would like to add?

Joe Kaderavek: Andrew has touched on a number of points that we firmly believe in. From a company perspective, the project success is based on a number of areas, where we're looking forward to our collaboration with Honeywell. Energy is a big part of our costs and optimizing energy, through the use of data and capture and optimization techniques, is extremely important. Labor is a fundamental cost, as it is in all operations. The ability to train our people, with simulations, to understand and work with the equipment is an important process. This is a unique plant for our guys to deal with and it's important that the training and the data is there to support that.

Andrew touched on and I strongly support equipment optimization, so I'm looking to optimize operating hours and performance outcomes. They will make a difference between being in or out of operation, at certain parts of the cycle, - this is very important as is safety. Safety is our primary concern and the data systems and the lessons for our guys from this collaboration are critical.

Dr. Allen Alper: Well, Joe, that sounds like collaboration, with Honeywell, is really outstanding and a model for others. It sounds like that will help you be very competitive, safe, and also efficient. So that sounds great! Andrew, is there anything else you would like to add?

Andrew Hird: Yes, thank you. Andrew Hird from Honeywell here. I think Cobalt Blue is in a unique position. We primarily work with large greenfield and brownfield mineral processing companies. A lot of management changes come with trying to implement data and analytics and digital transformation, in a brownfield company. What's really exciting about this project is the ability to design that and not just from project execution, but very early on. We were engaged with Cobalt Blue right at the start. We worked hand-in-hand with them to design the plant, scaling the plant from pilot to demo to production. We do the modeling to make sure that the process will be as efficient as possible from a mineral processing point of view to an energy and yield point of view.

And we design the data and analytics into the project as we go. So, from start-up, we're going to have access to all the information required, on site and remotely, to control and optimize that plant. And that's very rare. Normally it takes years of running to then go back and try and optimize a brownfield environment. We get to do that from day one, which really helps Cobalt Blue hit that energy target and hit the production and capital intensity target that they've put up. And that's great to see the use of technology in the design phase, in the build phase and in the operating phase, rather than trying to come back at the end and sweat an asset where you can design all those hooks and handles up front.

The other part of the design that's critical is scalability. So yes, this project is big and very important, but as we work with Cobalt Blue, from a corporate perspective, we're going to make sure that any other projects that they roll out dovetail seamlessly into this and use as much remote operation, for support, as possible. Where Cobalt Blue has their process knowledge and the metallurgists, whether they're on the mine site, the mineral processing site, or in a corporate office, we're going to make sure all those people's knowledge is brought to bear to continue to optimize that project and have access to other sources of domain information, such as Honeywell, with our mineral processing experience and other technology suppliers to Cobalt Blue. That could be chemical suppliers. It could be equipment suppliers, making sure there's a completely connected ecosystem, where at the center is Cobalt Blue and on the spokes are all their sources of knowledge, to make sure they continue to operate this plant, in the safest, most productive, energy-efficient and cost-effective way possible.

And it's great to see someone with the vision to do that from the start, rather than someone building a plant and coming back, if you've made or haven't made your start-up curves, and then worrying about it later. It's so much more efficient to do this design, from a data and connected point of view, up front with Cobalt Blue.

Dr. Allen Alper: Well, it sounds like Cobalt Blue and Honeywell have an outstanding collaboration. It’s great that it started, in the very early stages of development of the processing and project. We’ll publish your press releases as they come out so our readers/investors can follow your progress.

https://www.cobaltblueholdings.com/s

Joe Kaderavek

Chief Executive Officer

info@cobaltblueholdings.com

Level 2, 66 Hunter Street

Sydney NSW 2000 Australia

|

|