Ioneer Ltd (ASX: INR): Lead by a Proven Successful Team, becoming a Globally Significant, Long-Life, Low-Cost Source of Lithium and Boron with a Sustainable Future; James Calaway, Executive Chairman Interviewed

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 3/4/2021

Metals News, interviews James Calaway, Executive Chairman Ioneer Ltd (ASX: INR), a world leader in the lithium space. Ioneer is an emerging US lithium–boron producer and the 100% owner of the Rhyolite Ridge, Lithium-Boron Project, located in Nevada, USA, the only known lithium-boron deposit in North America and one of only two known such deposits in the world. On January 21st, 2021 Ioneer announced that its metallurgy and process engineering team successfully converted lithium carbonate, produced at its pilot plant, into battery grade lithium hydroxide, a key milestone in Ioneer’s lithium hydroxide development path. Ioneer assembled a team of world-class partners, like Fluor, Kemetco, Emerson, and Dupont. Ioneer Ltd. is expected to become a globally significant, long-life, low-cost source of lithium and boron, vital to a sustainable future

Ioneer Ltd.

Dr. Allen Alper: This is Dr. Allen Alper, Editor-in-Chief of Metals News, interviewing James Calaway, who is Executive Chairman of Ioneer. James, could you give our readers/investors an overview of your Company, and also go through the highlights of 2020, and what differentiates your Company from others? I know you have a great advantage, as far as costs, compared to your competitors.

James Calaway: Yes. Well, thank you, Allen. It's great to be with you. We are an ASX 300 Company. We're listed in the Australian exchange. But we are very American centric, in that our core asset is in Nevada, between Reno and Las Vegas. Most of our people, and now the majority of our Board, are here in the United States. So while our heritage is Australian, the vast majority of our people and the majority of the Board is American. We've transitioned to become a proud Australian company with a heavy American emphasis over the last couple of years as our Rhyolite ridge projects approaches start of construction later this year.

Our sole focus is on a globally significant lithium- boron project that we call Rhyolite Ridge. It is located in the high desert, between Reno and Las Vegas, about 15 miles away from the only current lithium production in the United States, which is a small amount of brine production by Albemarle.

We have unique mineral deposits that cover 2000 acres, with substantial long-life reserves and open in three directions. The mineralogy is sedimentary rock that outcrops and then has a gentle slope with thick, consistent grade and characteristics.

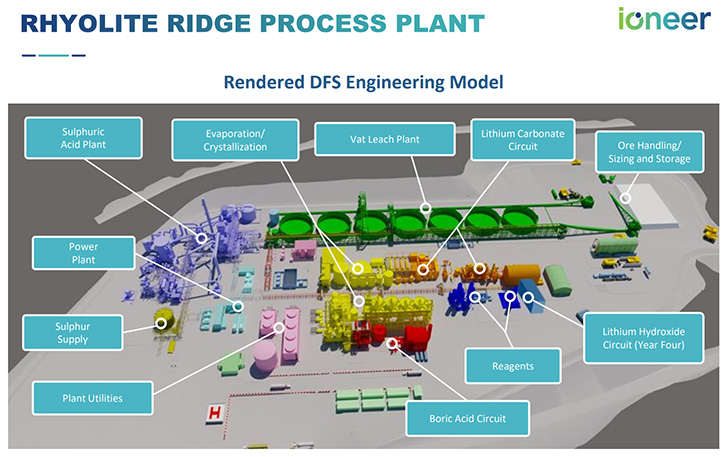

It's a borosilicate that is referred to as Searlesite. What is critically important is that the mineralogy contains significant amounts of both lithium and boron that we now know is readily leachable and can be processed into Lithium chemicals for the battery industry and boric acid for many uses, including most high-performance glass. This provides a dual stream of income, with high financial resilience, due to the nature of the boron market and allows ioneer to produce significant quantities of lithium chemicals, at the very bottom of the global cost curve. Allen, we are now at a very advanced state in the development stage of the project, having spent almost a hundred million dollars doing extensive test work and engineering, both of the mineralogy, as well as all the processing sequences that are necessary to extract the lithium and boron from those rocks economically.

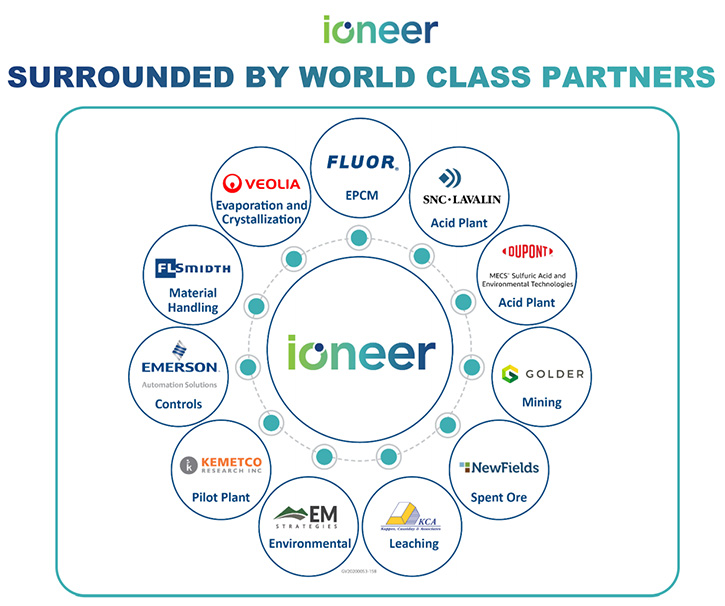

Fortunate for us, working with Fluor Corporation as our EPCM, and with the many other important contractors and research organizations, working on the project, we have developed a very robust, very mature, extremely low risk approach to our project.

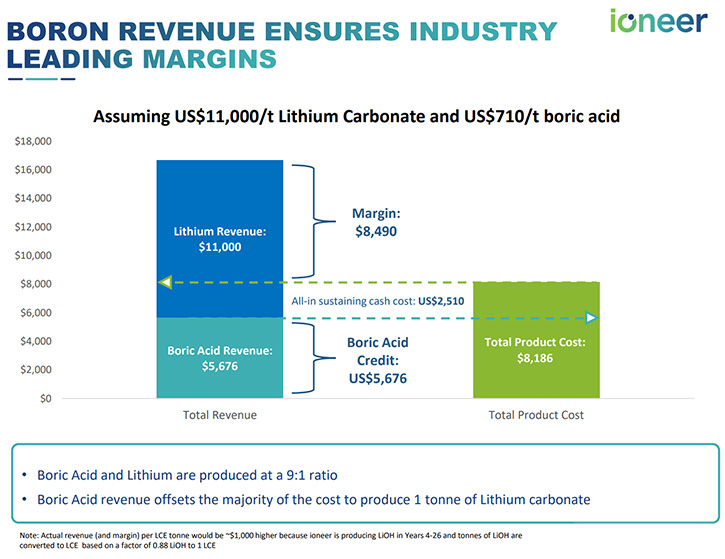

It is indeed remarkable that our mineralogy and developed and tested processes yield 9 tons of boric acid for each ton of lithium chemicals. When you take the credit from the boric acid sales from the total cost of operations, including the lithium, you end up with the lithium chemical production cost in the United States at $2,500 a ton. This means that Rhyolite ridge, in America will produce over 20 thousand tons of Lithium chemicals $1,500 lower than the next lowest cost production in the world.

Dr. Allen Alper: Fantastic. That's some advantage that you have.

James Calaway: Yes, it's quite an advantage. And of course, it's in the United States. An interesting thing has happened. During 2020, 2019, and even part of 2018, there was a negative sentiment in the lithium sector. But it was a short-lived negative sentiment caused by short term, easy pickings coming out in production, while the demand was not ramping up as fast as the supply. But over the last three or four months, the sentiment has dramatically shifted. I think part of it is just a proper recognition that the global demand, even if you give all the OEMs a haircut, is just going through the roof.

The second thing happened is that the global response to the electrification revolution is now complete. three years ago, all that anybody wanted to talk about was Chinese demand. In the last couple of years, everybody realized that Europe was dead serious and growing dramatically as well, which created a general uptick in sentiment, but still not quite enough yet. And then of course, there was last year’s Tesla Battery Day, where Elon Musk declared that his demand alone would use all the capacity by himself. People started realizing that demand was moving up faster than people thought. And then the final remarkable demand development is the election of President Biden, with his very strong position that the United States will lead the electrification process. A few days later, General Motors CEO stated that they're going to stop producing internal combustion engines by 2035. A few days later Ford followed. Simply amazing demand, growing globally and seemingly unstoppable

Dr. Allen Alper: That's amazing news. I think Biden also said all government vehicles will be switched to electric vehicles.

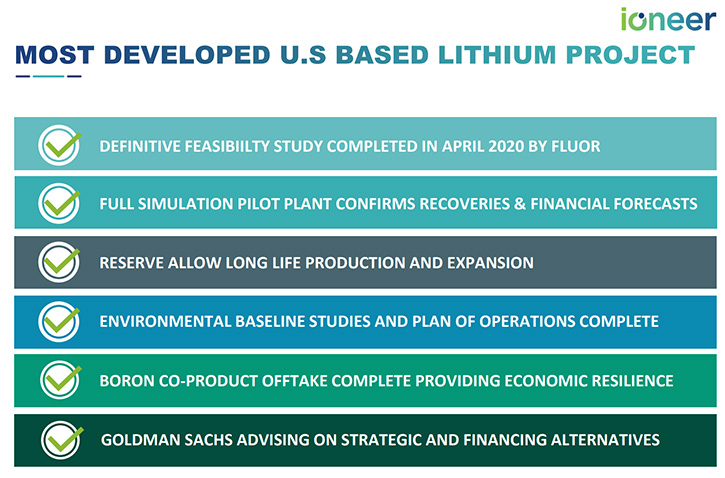

James Calaway: That's correct. And even just the notion that Apple may be teaming up with OEMs to make electric cars is remarkable as well, particularly given their heavy competencies in batteries and software are the driving technologies of electrification. The sentiment in the United States, both from a policy and practical perspective, to be fully committed to electrification, on top of Europe's growing serious commitments and the explosion in Asia, creates a remarkable demand forecast, even if you're a pessimist. That means you must have a lot of critical production coming on pretty quickly. We at Ioneer are very well positioned, given that we have the most advanced and low-cost project in America. We are the only project in the United States, Allen, that even has a definitive feasibility study. We are 10 months beyond the DFS and will be construction-ready from a technical perspective this summer. We currently believe we will be able to commence construction Q4, 2021 with first production anticipated late 2023. We believe that is perfect timing for our project.

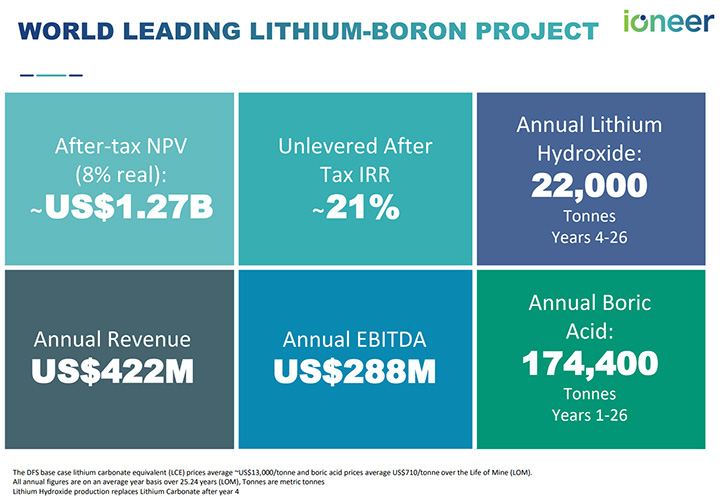

Our definitive feasibility study was finished last year in April. It is a 10,000-page, massive, very high-quality DFS, done by Fluor Corporation. We are now almost 60% engineering complete and expect to be shovel-ready, from an engineering design construction ability, by this summer. Assuming that the financing is finished, which we anticipate getting done between now and the summer, and as soon as we get our final permit from the federal government to start construction, we expect this year, somewhere in the second half, to be moving bulldozers in, and have a 24-month construction period. This phase one operation will allow us to produce 22,000 tons per year of lithium chemicals, and about 175,000 tons of boric acid. You know, it is an incredibly important project.

The part that is so interesting, if you look at the world of lithium, is the two companies I know of that have serious co-production are us and SQM, because they produce a lot of potassium, with their lithium, that they combine with their nitrates to be a leader in potassium nitrate. Similarly, we will be an important lithium chemicals producer and a globally, top three, boric acid producer. For both companies, this is an especially important economic advantage.

Dr. Allen Alper: It is great to be in such an excellent position and to have such low costs. Also, to be surrounded by world-class partners. Maybe you could tell our readers\investors a little more about that.

ames Calaway: Having been the Chairman of Orocobre, during the development of the wonderful Oloraz field, one of the things I learned was you must have fantastic engineering and flow sheet test work, with a keen focus on constructability and operations. We chose Fluor Corporation because they are one of the world's leading engineering firms. The good news about them and the many subs is they're absolutely talented. The bad news is they are very, very picky. So if all you're trying to do is just check the DFS box, something that you can sell to the financial market, they may not be exactly your cup of tea. That is because they don't put their name on things unless they believe in them, period.

That's exactly the kind of company I want to be our EPCM. They have made sure that we do the test work at the proper scales, and that their engineering is based upon sound, real test data, not based on plug in numbers all too common in Jr. mining company reports. Importantly, we have surrounded ourselves with leading equipment vendors and suppliers. People like Veolia, FL Schmidt and others, who have been heavily involved in our full cycle pilot plant, with a clear understanding, from that engagement, are going to be critical suppliers to the development of Rhyolite Ridge.

The advantage of Fluor and the equipment suppliers integrating into our test facilities is that they grow to have a higher level of understanding and the ability to understand the details to provide performance guarantees and reasonable proposals from a cost perspective. And with engineering at a highly advanced stage, we are able to enter into final equipment contracts in intelligent large packages.

I do not think anybody in America can credibly say that right now. Other than Rhyolite Ridge, nobody else has even produced a DFS of any standard.

Dr. Allen Alper: That's great to be in that position, and to have chosen such great partners to work with, who are so accomplished and so technical. That's great to supplement your Team. Could you tell us a little bit more about yourself and your Team?

James Calaway: Thank you for that, Al. All my life I have been building industrial capabilities from scratch. I came out of the University of Texas in economics, and I went to Oxford University and got my master's degree. I came back to my hometown of Houston and co-founded the first commercial space company in the United States, with the man who had at the time just retired as Head of Engineering at the Johnson Space Center. It's a long story. I was a little early for commercial space, but we did build a successful company out of that company, called Space Industries. Since then I have spent my life building companies in technical fields. In 2007 I began looking at batteries, electrification and transportation early on. Then ultimately, through a long series of technical moves and bringing teams together, I became an investor in and Chairman of a little Company called Orocobre.

When I invested and became the Chairman, Orocobre was worth $AU27 million. I was extremely fortunate to team up with the very able Richard Seville, the Managing Director at the time I entered the Company. We all worked ourselves to death, overcoming building the first new brine operation in twenty years, at 14,000 ft in the Andes of Argentina, with the Kirchner administration promulgating heavy socialism and strict import controls on everything. Just some minor challenges! And we built it. Not perfect, but remarkable indeed, given the circumstance. After we achieved commercial operations, I retired as Chairman, and shortly thereafter was approached by Ioneer’s able CEO, Bernard Rowe, wanting to see if I would be interested in a project of his in Nevada called Rhyolite Ridge. At first I assumed it was a lithium clay project. Based upon my concerns about operating costs for clay projects, I was less than interested. But when my technical team alerted me to the fact that there was a thick layer, with high lithium and boron, with low clay, I became fascinated and excited by the possibility for economic production. And as they say, the rest is history.

For the last four years, I have been working with Bernard and the terrific team we have assembled to drive our remarkable project to completion.

One of the things that I have come to realize is important, really important, and it's something younger people might not fully grasp, but I definitely think it's critical, is never underestimate the importance of governance and culture. I used to think it's all about just the idea, but it's not. Governance and culture are vital. And part of governance has to do with having people, who are committed to the objectives that you have. And our commitment is to become a very important supplier of the materials necessary for a sustainable future. And so everything we do is about that. We work every day, not only to show our commitment to that objective, but do it right, and only surround ourselves with people that believe in that goal.

And so this is very important. Part of the governance starts with your Board, and a lot of these young company Boards are made up of a bunch of people that mainly come out of the financial sector. There is nothing wrong with having some financial acumen.

We certainly have that, but I don't believe that, at this point, it is the most important thing. I think you need to have people that understand what it means to develop and create and build large capacity, industrial capacity. And John Hofmeister, our former President of Shell has been unbelievably helpful to us as a Board Member. Alan Davies, who was the former CEO of Rio Tinto's energy and minerals organization, unbelievably helpful to us! And we've just added two new Directors. Both are incredible people. Both are females, by the way, both from America, Maggie Walker is an extraordinary person. She was the worldwide head of Engineering, VP of Engineering for Dow Chemical, and head of all their research facilities. She's one of the world's leading experts on how you properly, safely and effectively build and operate large scale facilities like Rhyolite Ridge.

I couldn't believe that we were so fortunate as to find her, particularly at this opportune time, when we're heading into that phase. She just joined our Board and we announced that last night in Australia. We also brought in Rose McKinney James, who is a key person in Nevada. She basically ran the Department of Commerce of the state and is a national leader in renewable energy. And she's the Chairman of the Board of the Energy Fund, which is one of the largest funders of renewable energy nonprofits in America. She is just an extraordinary person. And so we're building our governance structure, and everybody's committed to our objective.

And then of course the team, we have a great team of dedicated professionals and we're expanding and growing that team, but we have to do that in a judicious way, Allen, not to bloat our overhead in advance. This year is going to be a great challenge for us, executing our human resource strategy, building up the internal capacity and owner Team to be able to manage through the transitioning to construction, and the all-important commissioning phase. So that's our challenge. And, of course, getting the financing completed is another part, but I'm feeling awfully optimistic about that, Allen.

Dr. Allen Alper: Well, I must say that you've done an amazing job of putting a fantastic team together, getting them an outstanding project, and you have a record of accomplishment. You are a pioneer in the lithium space. I admire what you're doing very much.

James Calaway: Well, Allen, you're very kind to say that, but it is truly about the whole Team, and our commitment to our mission. But you know, I was talking to my daughter, who is a great doctor on the Yale medical team, and whom I love very much. She was talking to me, with loving care, about how hard I was working at 63. "Honey," I said, "can you imagine, a person so fortunate as to get up every morning and know why they're working and what is the guiding principle?" I know what that is, and that's to help save the planet, Allen. I don't look at this from a perspective of making a bunch of money for myself. I'm done with that. This isn't about that.

Now I know we have to build a highly financially successful Company, because if we don't do that we can't build the capacity to produce these materials vital to the project, but the driving impetus is to the environment. I think about my children and my grandchildren and all the youth of the world, what type of planet will we leave behind? And you know what, when you have that purpose and you can convey that and build an organization committed to those concepts, then you have, not a guarantee, but you have a chance to build something that's enduring.

We're going to build a massive capability and we're going to be the low-cost producer in America. That's going to be the base, on which we build Ioneer into an important Company. I hope that some of your readers/investors will hear our passion and study what we're doing. There's a lot on our website, which is www.Ioneer.com. We've posted our entire executive summary of our DFS, if you want to know what we're doing, read that, it'll lay it all out. And we've gone a long way since publishing that extensive document.

Dr. Allen Alper: You and your Team can be very proud that you're creating a legacy that will help the world lower cost and efficient energy, and green energy. So, that's really fantastic! You can be very proud of what you and your team are doing, and be proud of your legacy and your heritage.

James Calaway: Thank you, Allen.

Dr. Allen Alper: Could you tell our readers/investors the primary reasons they should consider investing in Ioneer?

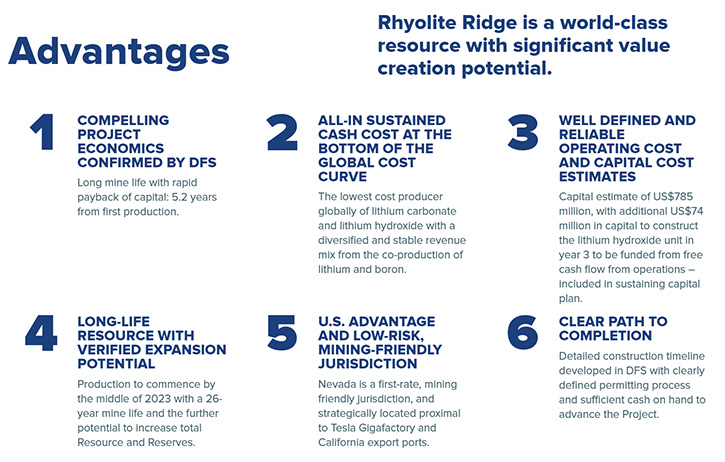

James Calaway: I think the reasons are: One, we're by far the most mature and understood development project in the United States by a significant amount. Two, we have assembled a truly outstanding team to execute, never underestimate that. Number three, we will be the lowest cost lithium production on the planet. Four, our project is large -scale, with a big reserve and resource to give us long life and expandability. Our boric acid credit gives us tremendous stability in our cash flow. So we can be in business when lithium volatility arises, but be extremely profitable in good times. And, we're in America, for God's sake, where the electrification revolution is exploding right before our eyes. To have all those things come together. All the opportunities right now, and all the opportunities over the next 12 months to deliver on these objectives, I think creates multiple catalyst opportunities.

Because we're a unique material, because people have to think about boron and because we're not like the hypers of some of these other projects, I think that even in this more robust market, we're a value buy.

Everybody will have to make their own investment decisions and judgment, but those are the main thing I would say. And the seriousness with which we have committed ourselves to really doing it right, should make a difference to people. Because, there're a lot of companies out there with similar valuations that are at preliminary feasibility study level, who have not demonstrated even a fraction of the seriousness, which we have. Ours, really is, I think, the highest return, lowest risk project there is in the United States. I believe that firmly.

Dr. Allen Alper: Well, those are very compelling reasons, James, for our readers\investors to invest in Ioneer. You have an outstanding company.

James Calaway: Well, thank you Allen, and I hope that you and I will have an opportunity to visit again over the coming months as we continue to execute on our plan.

Dr. Allen Alper: Well, that's great. I'm looking forward to it. I enjoy talking with you, and I'm really impressed with what you've accomplished. I love talking to accomplished people. People who have a vision and people who have accomplished their vision and know what they're doing, and know how they could not only help themselves, but help the whole world. That's great!

James Calaway: That's the combination that makes you have the capacity and will to overcome the challenges that invariably arise. Thank you, Allen. I look forward to talking with you again soon.

Dr. Allen Alper: Sounds great.

https://www.Ioneer.com/

Bernard Rowe

Ioneer Ltd

Managing Director

T: +61 419 447 280

browe@Ioneer.com

|

|