Vale’s Nickel Melt Rounds and Plating Rounds Get LME Acceptance; Interview with Juan Merlini, Vale’s Head of Marketing and Sales for Base Metals

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 1/11/2021

We learned from Juan Merlini, Head of Marketing and Sales for Vale's Base Metals business, that two refined nickel products, produced at Vale’s Long Harbour processing plant, in Canada’s Newfoundland and Labrador province, have been accepted by the London Metal Exchange as qualifying for physical delivery to LME warehouses worldwide. Vale is one of the largest producers of iron ore and nickel in the world, with its iron ore mines primarily in Brazil and nickel mines in Canada, Indonesia and Brazil. Vale also sells copper concentrate; the Company's copper mines are located in Brazil and Canada. Vale's primary goals for 2021 include building a more stable, reliable business, being obsessed by safety and risk management and becoming a leader in low carbon mining.

Vale

Dr. Allen Alper: This is Dr. Allen Alper, Editor-in-Chief of Metals News, talking with Juan Merlini, Head of Marketing and Sales for Vale's Base Metals business. Juan, could you give our readers/investors an overview of Vale's Base Metals business? Then tell them what recently took place with LME approval of your nickel products?

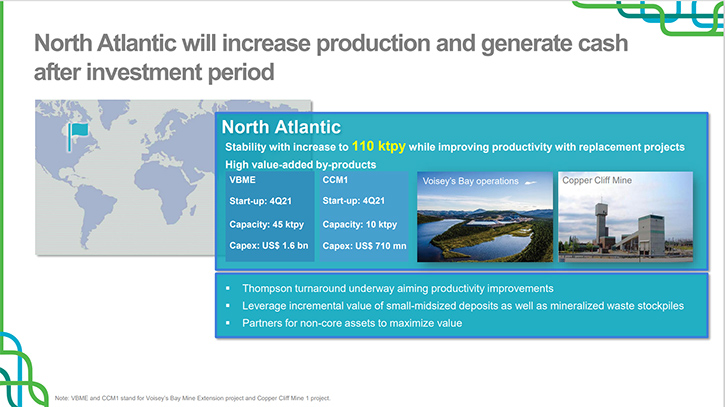

Juan Merlini: Thank you, Dr. Alper. Regarding base metals, as you know, we are one of the main nickel producers in the world. We produce 60% high-purity nickel in the forms of rounds, pellets, and powders. We have operations in Canada. We have operations in Indonesia and Brazil. Our production levels are around 200,000 and 210,000 tons of nickel. Aside from Long Harbour, our main sites in Canada are located in; Sudbury, Port Colborne, Voisey's Bay and Thompson as well as in the U.K. and Asia. We call this the North Atlantic flow sheet. We have some of our products listed on the LME, our nickel pellets. Recently, our Long Harbour Plating and Melting Rounds were listed under the LME as well. This demonstrates very important recognition of the value that the London Metal Exchange brings to our industry and our product. The registration of the melt round and the plating round is part of the evolution of our operations in Newfoundland and Labrador and contributes to increase the liquidity of our products in the market.

Co Drums 1

Dr. Allen Alper: So this development gives you the approval to ship to LME warehouses all over the world. Is that correct?

Juan Merlini: Correct.

Dr. Allen Alper: Could you tell our readers/investors a little bit about the properties of your products and the uses and the markets for your products?

nickel melt rounds

cobalt round

Juan Merlini: Our Vale melt rounds conform to the purity requirements of the globally-recognized ASTM B39-79 standard and contain a nickel content of 99.8% or greater. The Vale plating rounds are high-purity rounds, specifically designed for electroplating. The typical purity is about 99.95%. We have two types of products that are being used, the melt rounds for the melting applications and for alloys, and the plating rounds, where very high purity nickel is required for plating applications.

Dr. Allen Alper: Could you tell us a little bit more about those applications and why nickel is so critical, the properties of nickel, to satisfy the requirements of those applications?

Juan Merlini: On the melting side, we are talking about alloys for several different applications in the aerospace and energy sectors. Nickel is very important for providing chemical composition of the alloys. A very high quality is required in order to ensure that the specifications of the alloys are realized, as required by the final customers, for their various specific and critical applications. In the case of plating, it is a process that also is required through some activities, like electroplating, mainly in the automotive industry and in the motorcycle industries, where you have all these parts, components that require a very shiny, very bright aspect. Nickel is one of the elements that provides that form. A very high quality and purity nickel is required for these processes.

Dr. Allen Alper: Nickel, from my understanding, enhances corrosion resistances, is that correct?

Juan Merlini: Correct. One of the plating usages is not only to make it shinier and beautiful, but also to address the corrosion and the strength of the material as well.

Dr. Allen Alper: Are you gearing up to serve the electric vehicle market?

Juan Merlini: Yes, we are targeting the electrical vehicles market. Currently these products, the melting and plating rounds, are not being used heavily on electric vehicles. I understand that there are some tests being completed however, and we foresee that in the future, there will be a deficit in the nickel market. These products could fulfill upcoming electric vehicle demands.

Dr. Allen Alper: Could you describe Vale's mining to market process, ability and capability?

Juan Merlini: The process to extract the nickel is a complex one. We start with our mines. We have underground mines and open pit mines depending on the type of ore. And we have a processing route that leads, in some cases, to smelting and refining. In other cases, a hydrometallurgical process is used, which is what we have in Long Harbour, where the final product is a high purity nickel. We work with very high environmental, social labour standards. It is a complex process. We have been part of the nickel industry for more than 100 years and we are positioned to fulfill our customer's needs with the different types of nickel that they require for their different applications.

Dr. Allen Alper: Excellent! Is Vale number one in the production of nickel?

Juan Merlini: We are currently among the top three.

Dr. Allen Alper: Could you tell our readers/investors Vale's primary goals for 2021?

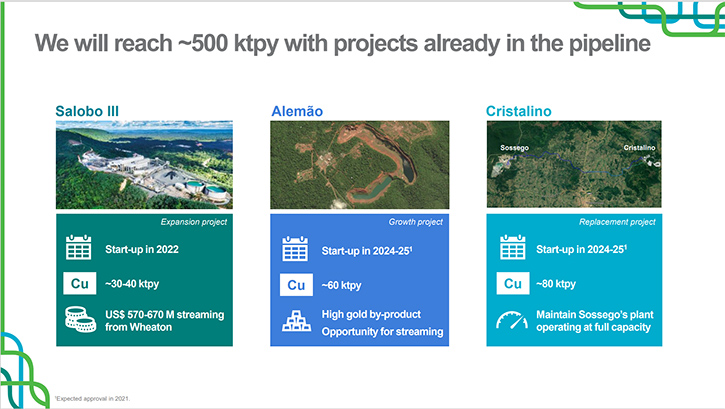

Juan Merlini: Yes, we will continue our focus to have a stable and reliable business. We will continue our important investments on the nickel side, which includes the conclusion of our Voisey's Bay underground mine. It's a very important project to provide the supply of nickel and cobalt for our refinery in Long Harbour. We will continue working on our Canadian assets to improve their stability, reliability and productivity in order to maintain current production levels. We have some projects in Indonesia, which we are working on developing. We also have a very strong growth plan in copper, where a priority is to conclude our Salobo 3 project.

We have several other projects in the Carajás region in Brazil, like Alemão and Cristalino, which will be important enablers for growth. In addition, with the opportunity that we have in Canada to grow our copper and nickel platform, such as the Victor project.

Dr. Allen Alper: Could you tell our readers/investors what's happening in the copper market? I know it's an exciting time for copper.

Juan Merlini: Yes, for sure. For the copper market, on the demand side we are seeing a very robust demand coming from China, but also from the rest of the world. All the electrification that's going on is in part driven by the electric vehicles, but also by the renewables, on the energy renewable side, on top of the industrial applications that continue to grow, we see a very strong demand for copper. On the supply side, it's a very tight market. In 2020, the industry experienced disruptions due to COVID-19. It's a very tight market. The future supply that is needed to fulfill the demand will come from more complex regions that will require more complex operations and logistics. There is an expectation that the incentive price of copper, to deliver the future supply, will need to improve. It's a very positive outlook for the copper market.

Dr. Allen Alper: with electrification increasing, with electric vehicle., I would think that it's going to be a strong growth market. What are your thoughts?

Juan Merlini: Yes. We are seeing very positive data points, coming from the electric vehicle side. I think there is a trend of decarbonization, the support, we are seeing, from the governments to achieve these reductions on CO2 and also all the investments going into the supply chain. The reduction on the cost of the batteries is really fostering the electric vehicles industry. We foresee a very strong outlook for the electric vehicle market.

Dr. Allen Alper: Could you tell our readers/investors a little bit about what Vale is doing with cobalt?

cobalt round

Juan Merlini: We've continued to produce cobalt from our operations in Long Harbour and Port Colborne. This is a by-product of our flow sheet, part of our pipeline that will continue resulting in cobalt units.

Dr. Allen Alper: Could you tell our readers/investors the primary applications and markets for cobalt?

Juan Merlini: Currently, the main market for cobalt is for batteries. Not only for the EVs, but cell phones and other electronics. This comprises most of the application for cobalt. There are other industrial applications, but the main one is definitely for batteries.

Dr. Allen Alper: Any final comments on the LME Certification for Long Harbour Rounds:

Juan Merlini: Long Harbour certification under LME is a very important achievement. Vale has always recognized the value that the London Metal Exchange brings to our industry. Registration of Melt Rounds and Plating Rounds is part of the evolution of our operations in Newfoundland and Labrador – from discovery to a mature producer – and contributes to increased liquidity for our products in the market, The Long Harbour processing plant has an annual production capacity of 50,000 metric tonnes a year. It combines state-of-the-art processing technology and world-class environmental management practices to produce environmentally friendly nickel. The plant is located about 100 km west of the vibrant port city of St. John’s in Newfoundland and Labrador. In addition, Vale’s other LME-registered products include Nickel Pellets from Sudbury, Canada and Clydach, U.K., and Cobalt Rounds produced at Port Colborne, Canada

Dr. Allen Alper: Congratulations! Thank you for sharing the news that two refined nickel products, produced at Vale’s Long Harbour processing plant, in Canada’s Newfoundland and Labrador province, have been accepted by the London Metal Exchange, as qualifying for physical delivery to LME warehouses worldwide.

http://www.vale.com/

Vale.RI@vale.com

|

|