ioneer Ltd (ASX: INR): Low-Cost Project for the Economic Production of Lithium Carbonate, Lithium Hydroxide and Boric Acid, Interview with James Calaway, Chairman

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 6/1/2020

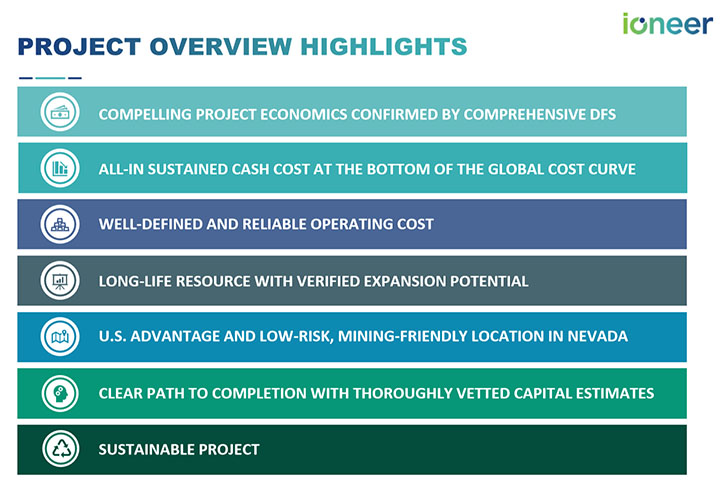

ioneer Ltd (ASX: INR) is the 100% owner of the Rhyolite Ridge, Lithium-Boron Project, located in Nevada, USA, the only known lithium-boron deposit in North America and one of only two known such deposits in the world. The Definitive Feasibility Study (DFS), released April 30, 2020, places Rhyolite Ridge as the single most attractive, lowest cost project for the economic production of lithium carbonate, lithium hydroxide and boric acid globally. In addition, the DFS confirms that the project has the most stable overall operating cost structure, for the production of lithium carbonate and battery grade lithium hydroxide, due to the scale and reliability of its boric acid credit. We learned from James Calaway, Chairman of ioneer, that next steps include starting the 12 month formal process of obtaining environmental permits. Rhyolite Ridge is expected to become a globally significant, long-life, cost-effective source of lithium and boron, vital to a sustainable future.

Rhyolite Ridge Lithium-Boron Project: Outcropping, high-grade, lithium-boron mineralization (white hill)

Dr. Allen Alper: This is Dr. Allen Alper, Editor-in-Chief of Metals News, interviewing James Calaway, Chairman of ioneer Ltd. James, could you give our readers/investors an overview of your Company?

James Calaway:ioneer Ltd is Australian listed company under the symbol INR. For the last four years ioneer has been focused exclusively on the development of the Rhyolite Ridge Lithium-Boron Project in the state of Nevada. We have a project with a unique mineralogy that is fairly thick with consistent mineralogy, covering about 2,000 acres. It outcrops and will be mined, with a simple open-pit mining operation.

The reason this particular mineralogy is so important, is that the ore produced has both a significant amount of lithium as well as a very large amount of boron in the rock. It also has low clay content that makes it amenable to efficient leaching, with diluted sulfuric acid. So the material, when it's subjected to about three days of leaching, essentially soaking in a warm sulfuric acid mix, it releases into solution a little over 90% of the lithium and boron in the rock.

An advantage of this unique ore is that when you drain the fluids that have leached the materials you want, you end up with a competent, dry stackable rock that is easily taken from the leach vats to a storage facility. There is no need for a tailings dam. So, it's a remarkable material in that it gives up what you want very effectively, but what is left behind is easily taken to a simple storage facility.

In a simplified description of the process, once the lithium and boron are in solution through sulphuric acid leaching, the resulting solution goes to what we call the boric acid circuit. We then cool the solution and about half of the boric acid in the solution precipitates. After that point, we have a less boron rich solution we call PLS, and the solution goes through a impurity removal stage We then process the solution through various crystallizers, evaporators, centrifuges and floatation cells to produce the rest of the boric acid and delivery the “mother liquor” to the lithium carbonate circuit. Importantly, all the steps taken utilize well understood technology and equipment.

At this point in the process, the lithium rich solution called “mother liquor” is very similar to high quality brine production, delivered from the ponds to a lithium carbonate plant. The key thing is, as you're removing the boric acid and you're removing the impurities in the previous section that I just described, you want to make sure your lithium and boron recoveries are very high. By developing and operating our extensive pilot plant, for over 2 years, our team developed the exact chemical engineering know-how and methods that achieved 85% recovery of Lithium Carbonate and 79% recovery of Boron, from leach to final marketable products.

Once the solution leaves the boric acid circuit, the process to make lithium carbonate or hydroxide is very similar to a brine operation. You neutralize the solution removing predominantly magnesium. Then you add soda ash. You have a lithium carbonate reactor, and out comes wet lithium carbonate. The wet lithium carbonate is then washed, dried, bagged, and dispatched to market.

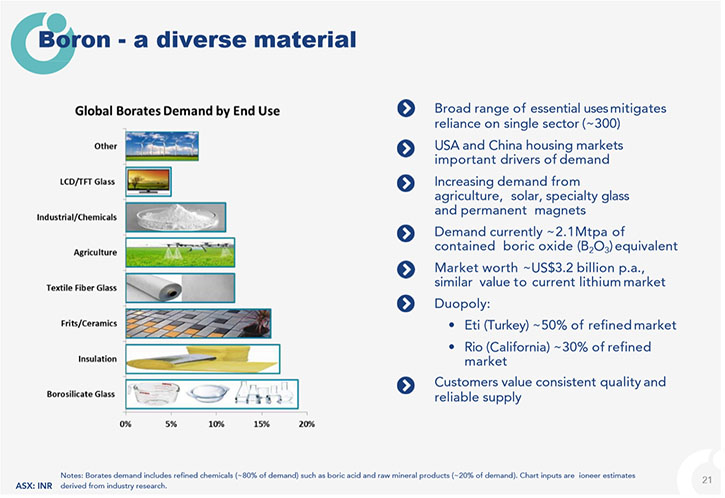

So the interesting thing is, and this is something a lot of people may not understand, but I know you will, it's not like you could take our rock and just get the lithium. In the process of getting to the mother liquor for the lithium circuit, you need to remove all the other material. While doing that removal, you end up with an enormous production of boric acid, which, of course, is a very important commercial material, with over 100 applications. Rhyolite Ridge will become the third largest producer of boric acid in the world.

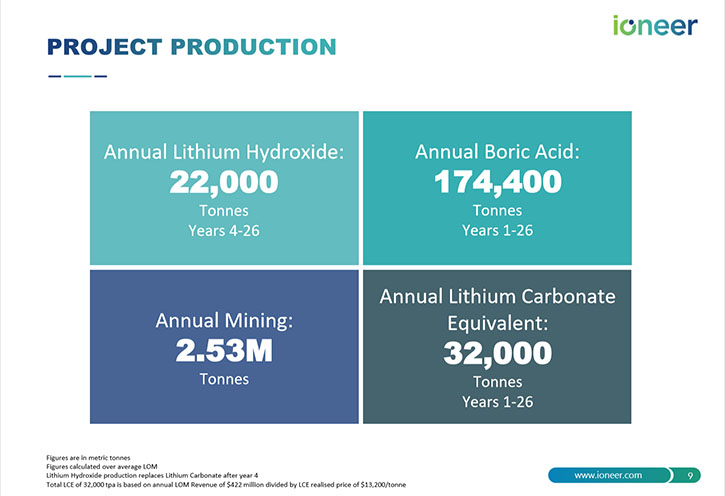

Overall our production will be over 20,000 tons a year of lithium carbonate and about 174,000 tons of boric acid. In year 4, carbonate will be converted into about 22,000 tons of lithium hydroxide. With the revenue from the boric acid production, most of which is already committed under offtake and sales and distribution agreements, offsetting the all in operating cost, we end up with a cost to produce lithium carbonate and ultimately, even lithium hydroxide at about $2,510 per metric tonne.

Our unique mineralogy, which no one else has, and our ability to mine it inexpensively and produce very efficiently with low losses, places our project, in Nevada, as the lowest cost lithium producer in the world. So that's why this project is so significant.

Dr. Allen Alper: Well, that sounds excellent. Could you tell our readers/investors your primary goals for 2020?

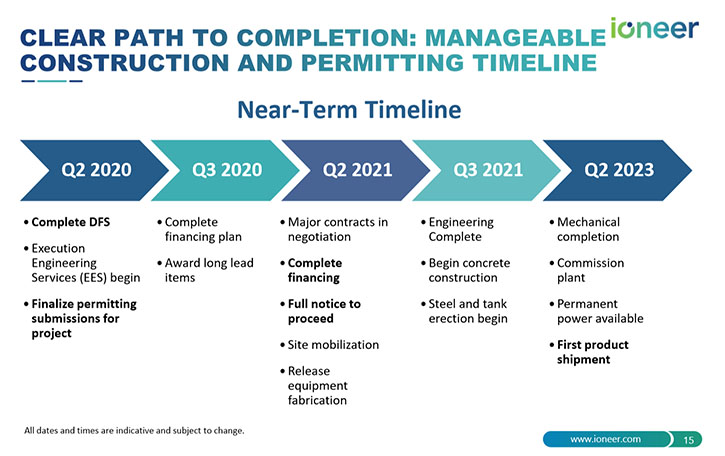

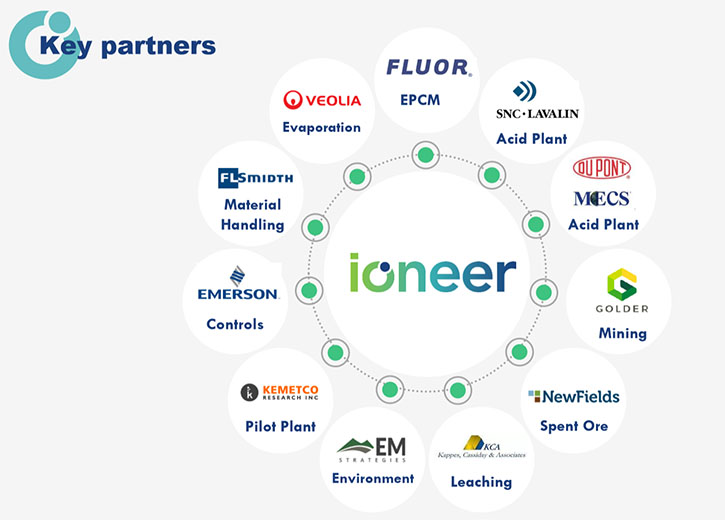

James Calaway:ioneer has just delivered the first definitive feasibility study for lithium in the United States, in many years. There are other companies, with lithium only projects in the United States, but they do not have the all-important boric acid credit, and they have yet to produce a rigorous definitive feasibility study, with trusted engineering firms like our engineering firm, Fluor. We put together an “A” technical team, including Fluor, Veolia, F.L. Smidth, Emerson and many more. We did a major company quality DFS. That was our big first milestone for this year. During the remainder of this calendar year, now that we've completed this 5,000 page definitive feasibility study, and submitted our formal application for what's called the Plan of Operation to the Bureau of Land Management, with 14 environmental baseline studies that kicks-off the 12 month environmental review process, we will focus our time on three things for the remaining part of this year. First, we will continue to move forward, aggressively, to complete all the engineering required to be shovel ready as soon as the environmental permit is approved. Second, we will support the environmental approval application process to deliver a timely and favorable decision by the US Government. And third, now that we have a very clear and economically attractive project, as shown in the DFS report, we will be actively engaged in completing the project financing process. Our goal is to have a shovel ready project in early 2021, with an operational permit, and with strong partners in place to fund construction of this globally important project.

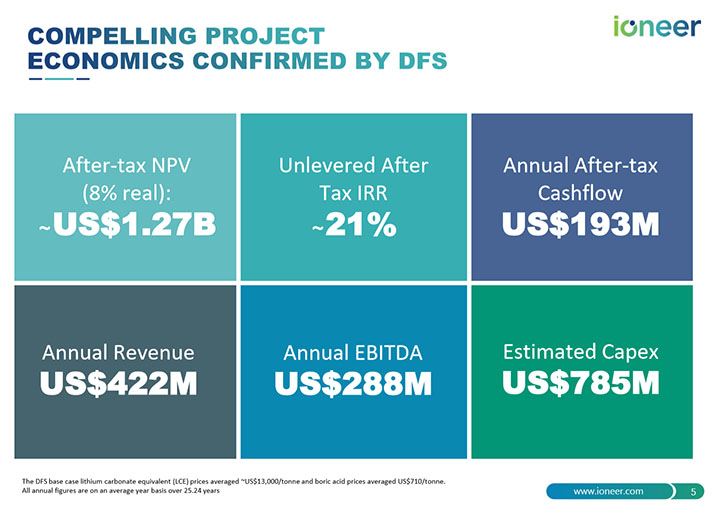

When a young company is lucky enough to be solely focused on one $785 million project, with a long mine life, producing materials critical to a sustainable planet, in a secure country, that has a 21% unlevered after tax return, and a $1.2 billion after-tax NPV at the bottom of the global cost curve, one wakes up each day excited about being a part of such a special opportunity. The ioneer team and its collaborators, are very excited to complete the hard work before us and to commence construction of this important project next year. We also look forward to being a material participant in both the lithium and boric acid industries as we commence production in 2023.

As you well know, Al, lithium has been a very high growth industry, both on the supply and the demand side. As such, things invariably get out of whack, and you end up with some relatively high volatility in lithium pricing. Volatility creates risk and some of the high cost lithium producers are suffering terribly right now. The low cost producers, like we will be, are barely still eking out a living in these very difficult COVID-19 times. Our project is greatly benefitted by the fact that not only are we at the bottom of the lithium cost curve, with our boron revenue taken as a credit against our overall cost, but also unlike lithium, boron has been very low in volatility for over a hundred years. Part of that has to do with the fact that there are few large producers of Boron, and Boron is useful in over a hundred different applications.

Boron is incredibly predictable and it helps us to be able to be financially resilient during difficult lithium times. But the imbalances in the lithium market turn our way, we will be the low cost producers and generate quite extraordinary returns. In a nut shell, ioneer will be able to withstand the downturns in the lithium business, and be able to be extremely profitable in the good times. The boric acid credit is incredibly helpful to that objective and, of course, being in the United States doesn't hurt either.

So we anticipate, based on our conversations and our work that we're going to have very strong interest in the financing of our project. Completing the financing will be a very high priority for us in the coming months.

Dr. Allen Alper: That sounds excellent, sounds like you're in a great position to have the security of the boron production and marketing. Could you say more about some of the major applications of the boron you'll be producing?

James Calaway: It's used in all kinds of fiberglass and insulation materials. It's used in a whole cross section of different types of high-capability glass. For instance, a lot of boron goes into Gorilla Glass, all your cell phone glass, for instance. It goes into TFT glass for big screen TVs. It goes into glass surfaces for your stove tops. It goes into fertilizer. It goes into armor, believe it or not. This sounds like a small thing, but it's bigger than you think. It is particularly good as an abrasive for a powder abrasive that's used in polishing camera lenses. It goes into ceramics. Al, it's uses are quite remarkable. It goes into many things, from the most advanced glass, insulation, solar panels, et cetera. So it really is one of those materials that's used across many industries that are very important to a technological future.

Dr. Allen Alper: That sounds excellent. Could you tell our readers/investors a little bit about your background and your team?

James Calaway: First of all, our CEO, Managing Director as they call it in Australia, is Bernard Rowe, who founded the Company. He's a geologist by background and has been quite successful. He had a technical company looking for mining projects for mainly big companies. He'd spent 12-15 years prospecting for mainly copper, gold, silver all in the Nevada/Arizona area even though he's an Aussie. He developed a strong, very good reputation in the area for doing what he said he was going to do.

And then some geologists brought Rhyolite Ridge to him. It was sticking out of the ground and they knew it had lithium in it. They weren't thinking about the boron. They were just thinking about the lithium. Lithium was hot, and Bernard thought it was an interesting project, so he locked it up in an option. He called me through a friend of mine in Australia. The reason I think he called me is because, for eight years, I had been the Chairman of the Board and had been a part of Orocobre’s Olaroz development from early on through to commercial production, which is now one of the large low-cost producers of lithium from brine in the world.

He knew I had just retired as Chairman of Orocobre and would have an understanding of what it takes to develop from scratch a new lithium operation. When Bernard called to discuss his project. I was pretty skeptical about it, to tell the truth. I had always associate Nevada with lithium clay. I also knew that there had been a lot of work on lithium clay projects in Nevada and even in Northern Mexico, but it never seemed to get anywhere. These lithium clay projects, while having large lithium resources, seemed plagued by how difficult it is and continues to be, to figure out how to remove the lithium from the clay economically. That was my view then, and to this day. so i thought he was trying to get me involved in another lithium clay project, and I would have no interest in investing my money and time on such a venture.

So I thought that Rhyolite Ridge was just another lithium clay project, but agreed to take a quick look to be sure. So I asked a very knowledgeable technical guy from my Orocobre days, a great lithium chemist, to take a quick look at it for me. At first he thought it was another lithium clay project and advised me as such. I was out. But Bernard asked him to do some work for him after I had decided to pass. In the end, he's the one who really opened Bernard’s and my eyes to the fact that we do have a big lithium clay layer that sits right on top of the lithium-boron strata. You take off the overburden and you get to a lithium clay and then you get to the 20 meter (60 feet) thick lithium-boron section.

He was looking at all the cores for Bernard and me, and he said, "My gosh, I don't think much about that lithium clay. I think that's really risky and difficult." He still thinks that, but he said, "My goodness, this lithium-boron section here has a very low amount of clay," like around 13% clay, which is no problem compared to the lithium clay section, which is like 80% clay. He said, "My God, this might work. This might process very nicely to produce both boric acid and lithium." it was that attention to detail and his brilliance that in the end began this wonderful relationship and investment of capital and 4 years of work on Rhyolite Ridge.

I’ve grown to have great admiration for Bernard’s judgment and his talent and his ability with people. We have been working very hard to build up a strong and capable team. We have an outstanding head of engineering, Matt Weaver. We have a terrific processing team. And we have surrounded ourselves with great people. This is a world class project, so we need to have world class people who can really dig into the details and make it happen.

So we hired Fluor to be our engineering firm. We've surrounded ourselves with the top people, equipment providers and technical people in the industry. We have the top leach experts in the world with Kappes, Cassiday & Associates, and with Fluor's leadership we proceeded to build this fantastic outcome in the DFS. So that's the team. It's grown. It's very tight. It's made up of committed people. We're really committed to building a company that's capable of producing, economically, the materials that are important for a sustainable planet. That's our saying, but the people that are on our team are very committed to this environmentally friendly future, which includes electrification of transportation, includes good technical materials for a variety of things and includes being able to store intermittent power. So that's what we're focused on. And this project is the perfect platform for us to do it.

Dr. Allen Alper: Oh, that sounds excellent. Could you summarize just the highlights of why our readers/investors should consider investing in your Company?

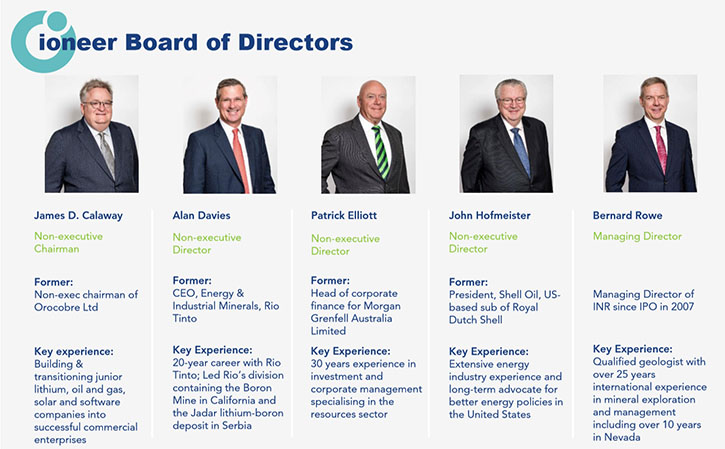

James Calaway: Well, it starts with integrity. We have a terrific Board. The former President of Shell Oil is on our Board, John Hofmeister. Alan Davies, who used to be CEO of Rio Tinto's Energy and Minerals Group, outstanding guy. Pat Elliott, a very respected guy in the financial world in the Australia, New Zealand area. I am one of the few people, who have actually been a part of developing, from scratch, a full blown lithium project, with all the learnings that come from such a challenging experience. And I've been devoting all that experience, applying it to the development of ioneer.

So one of the problems, with a lot of young companies, is they just don't devote enough energy to the technical details required to actually do something like this. People should look carefully at our DFS, and they should have confidence from what we're planning to do. Beyond that the core things are, we have a one-of-a-kind asset in the world and we're going to build the first big lithium-boron mine on the planet. Because of the results from all the work we've done, over these years, and the many tens of millions of dollars in pilot plant work at Kemetco Research, we can now be confident that we're going to be the lowest cost lithium producer in the world, by a substantial margin, and in the most stable geographic place on the planet, in a mining friendly state.

I suspect that will get people’s attention! We and everyone, who has been following us closely, have reacted to this DFS report with, "Oh my goodness. That is absolutely terrific." This is a good time to research our Company, because ioneer (ASX: INR) has really something special here. For your readers/investors, I also recommend going to ioneer’s website, www.ioneer.com, and taking a look at our video that summarizes the DFS work, and will help them visualize our project.

Dr. Allen Alper: That sounds excellent! Very compelling reasons for our readers/investors to consider investing in ioneer. We’ll publish your press releases as they come out so our readers/investors can follow your progress.

https://www.ioneer.com/

Bernard Rowe

ioneer Ltd

Managing Director

T: +61 419 447 280

E: browe@ioneer.com

|

|