American Manganese Inc. (TSX-V: AMY, OTC US: AMYZF, FSE: 2AM): Recycling Lithium-ion EV Batteries; Interview with Larry Reaugh, President and CEO

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 2/2/2019

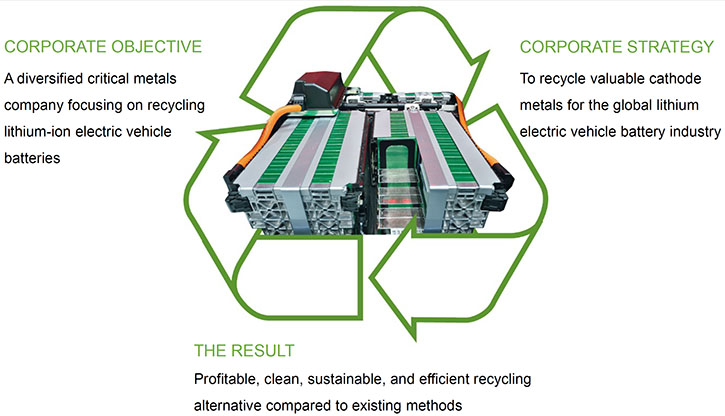

American Manganese Inc. (TSX-V: AMY, OTC US: AMYZF, FSE: 2AM) is a critical metals company, with a patent approved process for the recovery of metals from lithium-ion batteries, such as cobalt, lithium, nickel, manganese, and aluminum. Using a novel combination of reagents and unit operations, American Manganese can provide 100% extraction of cathode metals at battery grade purity. At the 2019 Vancouver Resource Investment Conference, we learned from Larry Reaugh, President and CEO of American Manganese, that they have built their pilot plant and it has recently been delivered to the Kemetco testing facility. They have also signed a Memorandum of Understanding with a Dutch private company, called Battery Safety Solutions B.V., for the purpose of forming a partnership to create and commercialize a closed-loop circular economy solution, for the upcycling of lithium-ion battery cathode materials. Their goal is to be commercially ready by late 2019 and become the industry leader in recycling spent electric vehicle lithium-ion batteries.

Dr. Allen Alper: This is Dr. Allen Alper, Editor-in-Chief of Metals News, at VRIC 2019, interviewing Larry Reaugh, who is President and CEO of American Manganese. Could you give our readers/investors an update on what's been going on since the last time we interviewed? Also for the benefit of the thousands of new readers/investors, who have joined us since our last interview, could you give us an overview of your Company, Larry?

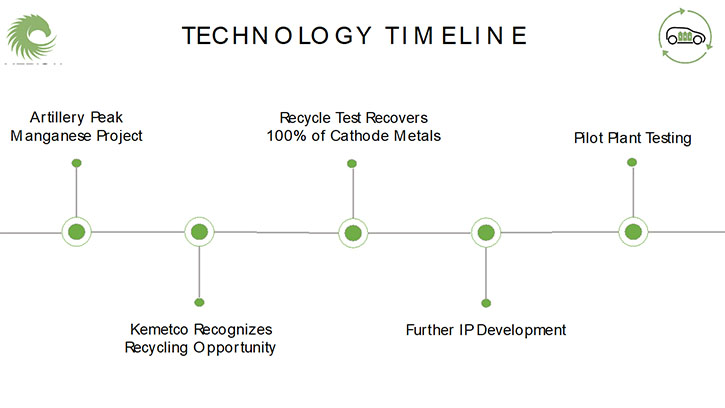

Larry Reaugh: American Manganese, as the name suggests, evolved from a manganese project in Arizona, USA from 2008 to 2012. We developed several billion pounds of manganese, averaging two to three percent manganese. That rock you would walk over if you're a manganese miner. Most deposit grades are 30 to 50% in other parts of the world and that's what the Chinese process. That's what everybody processes. Manganese is a critical metal. You can't make steel without it. Steel's too brittle if you don't add at least one percent manganese. We did a pre-feasibility study back in 2012, and to put the mine into production, we developed a metallurgical process and we thought we had everything, but we didn't have the manganese price, which kept sinking. Commodity prices are the enemy of anybody wanting to go into production. Today it's profitable, tomorrow it's not. You have to hit that window. And we missed it. But in 2015 Kemetco said, I think we can recycle the cathode metals out of lithium-ion batteries, using your manganese recovery process, or part of your process.

I put up the money and they did the initial proof of concept testing. Sure enough they got a hundred percent of the metals back. I just had a guy come by here and say, “You can't get a hundred percent. There're always losses.” You've got to realize this is a closed circuit and there's no grinding, nothing like that going on.

The grade of the cathode material is a hundred percent and you get a hundred percent back. That technology has now been patent approved by the U.S. Patent and Trademark Office. We expect to have the actual patent number issued by the patent office anytime soon.

We started looking at what they call scraps. Scraps are the material that never ends up in a battery. What happens is you do a battery run and something’s out of whack, in the formula, and they scrap it. So you get all these sheets of aluminum with cathode material on them. That could represent five to ten percent of the total batteries produced a year. That's a big number.

With scraps, you don't have to disassemble batteries to get at it. So, we've identified a source for tons of battery material a day. We've completed a business plan on a three tonne a day plant and it will pay for itself in about 14 months.

Now, we have identified that we could source as high as 40 tonnes per day, so that's great. That's our next move. It’s going to be our first commercial plant. Then we look at the actual dismantlement of the batteries, which are the size of my thumb. So you can get down to the foils inside. Copper foil for the anode, and the graphite and there’s aluminum foil containing nickel, manganese, cobalt, lithium and you want to get down to that because that's where you have to get the cathode material from.

We've developed a technology, because we need it to treat foil that is from scraps. The method is a novel invention that separates the active material from the aluminum foil.

So we're already there on that one. We've entered into an MOU with q Netherlands Company, Battery Safety Solutions B.V. Their factory processes 90 percent of the batteries in the Netherlands, approximately 5,000 tonnes per year and they're a private company.

We were looking at the disassembly, but they have developed a method of shredding. They have sent us the material and from initial tests we have high 90 percent recovery. We believe our technology is the best match for them after shredding because the alternative method for them is smelting, where you lose most of the metals and produce a waste slag material. Then recover only 40-60% of the cobalt .It's not efficient. It's dirty and it's not helping the environment by much. If the slag goes back into the environment, what are you going to do with the slag? It's loaded with nickel, lithium, cobalt, manganese and other ingredients.

So, this seemed to have closed the loop for us. At least in Europe. Because we're still working with a group that is working on a method of disassembling the battery itself. But for Europe we entered an MOU, we'll be closing that out sometime early this year and I think it's a great marriage.

I love their technology, they love our technology. So that's a good start. Now we havet the pilot plant built and delivered to Kemetco and we are going to start our testing.

The other thing that excites me is that the Department of Energy has announced that they are going to put 15 million dollars into studies in their labs on lithium-ion battery recycling.

There are five million dollars in prizes. We already have what they are looking for. They know all about us. We were in Iowa for one of the Critical Metal Institutes, AGM's several months ago.

I'd have to say, if they are looking at processes for recycling of the batteries, we would be a shoe in for a winner because we get 100 percent of it. But, Canadian companies may not be able to participate.

Dr. Allen Alper: It sounds like you are in a great position. It sounds like you've come a long way in recovering metals from batteries and that marketplace is growing very rapidly.

Larry Reaugh: Well Al, I've gone through skepticism two years now and a lot of writers are writing that you can't economically get the batteries metal out. I just point at the value on the board. It says 100 thousand electric vehicle batteries have 340 million dollars’ worth of metal. That's only for 100 thousand batteries.

So now you are starting to hear more about recycling. Governments are starting to get involved and the writers are talking about recycling. We've been mentioned in Bloomberg a half a dozen times by writers and so, they are becoming aware of us and I think this is our year to shine.

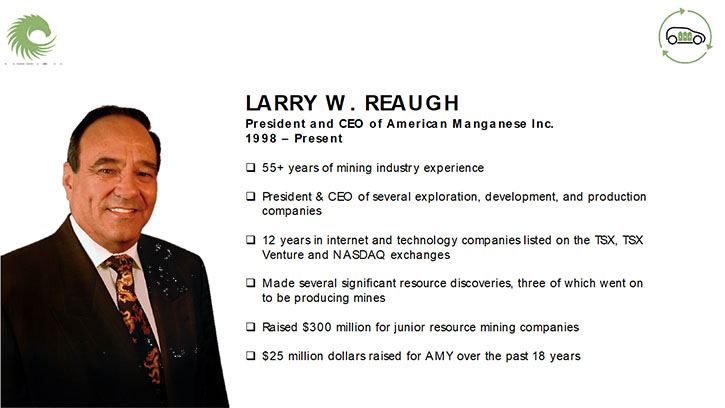

Dr. Allen Alper: That's excellent. Could you tell our readers/investors a little bit more about your background, your team?

Larry Reaugh: I've been involved as CEO for 40 years in several companies. I've had at least three discoveries that went into production. The best was my Rea Gold Company that went into production in 1989. It was a darling of the stock market in 87. Another one in Costa Rica eventually went into production. One in Arizona went into production. So I've had a good, successful career.

I got involved in bigger projects, like feasibility studies and hopefully trying to raise the money for production. I've done that in molybdenum and manganese and there was breaking ground, in those projects. We are the only one out there talking about recycling. We're not where we want to be, and we developed two disruptive technologies, from which we'll benefit. You know the eye is back on us for manganese and for the EV lithium-ion battery.

We have a circular economy solution. Nothing goes back into the environment and we can get the valuables out. My career has been exploration and discoveries. I have had a few of those.

Dr. Allen Alper: Now you've been working with a technology partner that's a laboratory. Could you say a little bit about that?

Larry Reaugh: We've been working with Kemetco. When we first got involved in manganese in the US, The US Bureau of Mines spent 60 to 80 years trying to come up with a method to produce electrolytic manganese metal out of the low grades in Arizona. They always ended up with a very costly and expensive and wasteful method of developing the metals.

We took all that information to Kemetco. Before that I went to three or four different labs and they repeated what the US Bureau of Mines did. That was going nowhere. So I talked to Kemetco. Norm Chow, the President said, “I think we can do this.” Thank God he did. We did a pre-feasibility study and then I put my money behind it. He is solid, really a genius when it comes to metal recovery and technology.

Kemetco is the second largest privately owned research lab in Canada.

Dr. Allen Alper: That sounds excellent, between you and Kemetco and Norm Chow. Excellent!

Larry Reaugh: Well I wouldn't go with anybody else.

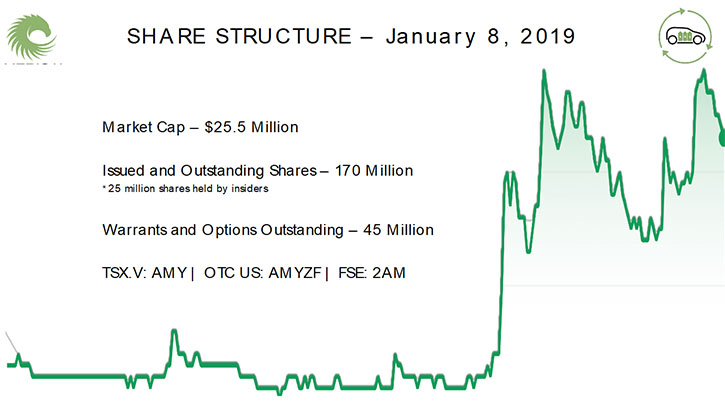

Dr. Allen Alper: That's great. Could you tell our readers/investors a little bit about your capital structure?

Larry Reaugh: We're a company that's traded on the TSX venture exchange, under the symbol AMY. We trade in the US under the symbol AMYZF. And we trade in Frankfurt under the symbol 2AM. We have 160 million shares issued and a market cap of 25 million. This is a real good entry point.

Dr. Allen Alper: That's great. What are the primary reasons our high-net-worth readers/investors should consider investing in in American Manganese, Larry.

Larry Reaugh: If you like technology, and you like mining, and you like specifically disruptive technology, then you should be looking at us. It's a mining company that has assets in mining, and we have a disruptive technology for manganese. We have a disruptive technology for lithium ion batteries. I see nothing but an upside. EVS are growing at a tremendous rate. There're tens of billions of dollars being spent on battery manufacturing every year.

I can see tens of billions of dollars being spent on recycling in the future.

Dr. Allen Alper: That sounds like an excellent opportunity for investors. Is there anything else you'd like to add?

Larry Reaugh: Well, we are raising money right now if anybody is interested in purchasing the stock. They should phone us.

Dr. Allen Alper: That sounds good.

Larry Reaugh: Thank you.

Dr. Allen Alper: Nice talking to you again. We've known each other for a long time. Glad to see how successful you are.

Larry Reaugh: This is going to be the biggest success in my career.

Dr. Allen Alper: We’ll publish your press releases as they come out so our readers/investors can follow your progress.

https://americanmanganeseinc.com/

Larry W. Reaugh

President and Chief Executive Officer

Telephone: 778.574.4444

Head Office:

#2, 17942 55th Avenue

Surrey BC

V3S 6C8

|

|