Ross Orr, President and CEO, BacTech Environmental Corporation (CSE: BAC, OTC Pink: BCCEF): Using Commercial Bioleaching Technology to Remediate Highly Toxic Tailing Areas

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 3/2/2017

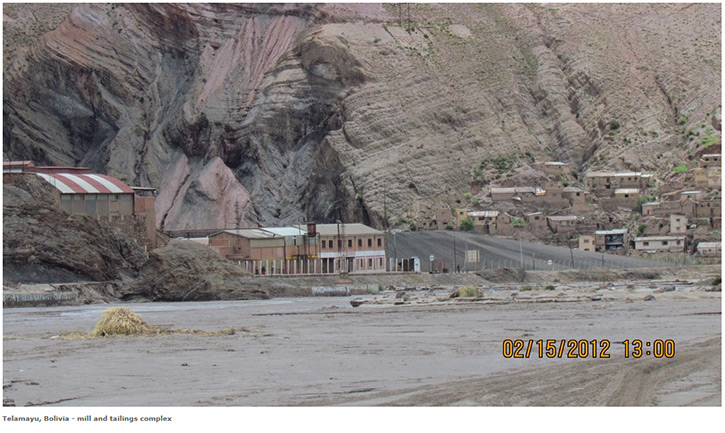

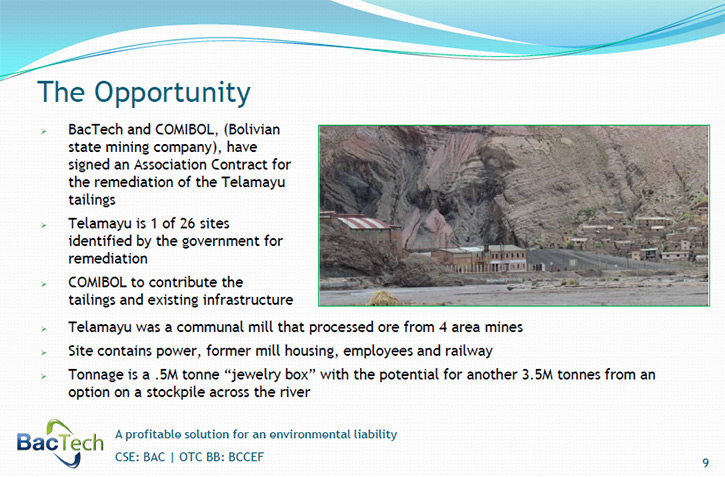

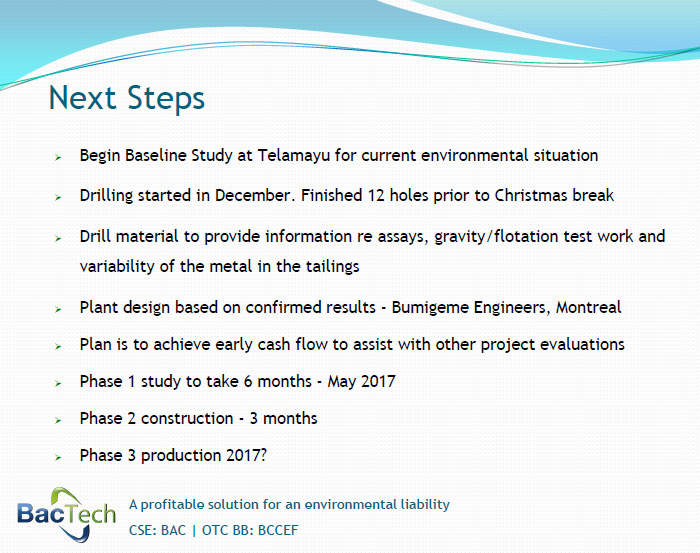

BacTech Environmental Corporation (CSE: BAC, OTC Pink: BCCEF) is a pioneering, environmental technology company that has developed and commercialized a proprietary technology to remediate highly toxic tailing areas resulting from abandoned mining operations. BacTech holds the perpetual, exclusive, royalty-free rights to use the BACOX bioleaching technology for the reclamation of tailings and mining waste materials. The company's principal focus is a high-grade silver/copper/tin tailings project called Telamayu, located in Atocha, Bolivia, in association with COMIBOL, the state mining group. According to Ross Orr, who is President and CEO of BacTech, this project should lead to cash flow later this year. Plans for 2017 include finishing drilling the tailings and moving on to metallurgy and then designing a simple gravity flotation plant by the end of the year.

Dr. Allen Alper: This is Dr. Allen Alper, Editor-in-chief of Metals News, interviewing Ross Orr, who is President and CEO of BacTech Environmental Corp. Could you tell me a bit about the vision, and focus of your company Ross?

Mr. Ross Orr: Sure Al, the basic technology we use is bioleaching, there are two of us that do that in the world, Gold Fields of South Africa, and ourselves. Gold Fields tends to do it for their own accounts. What we've been doing over the last many years, is trying to find the proper niche for this technology.

I think we've now figured out what that is. It's on the environmental side, because of the effective use of the technology, to oxidize sulfides that normally cause acid rock drainage, from tailings. Also it's very effective at stabilizing arsenic, as a ferric arsenate, which is a benign form of arsenic. I think this area of the environmental world, is really the niche area that we've been looking for.

Dr. Allen Alper: Could you tell me a little bit more about your technology, and a little about your projects?

Mr. Ross Orr: The technology I mentioned is bioleaching. We use naturally occurring bacteria that oxidize sulfides (sulfides cause the acid generation in tailings), in large stainless vats that include agitators, so that the liquid inside the tank is continually being churned, and we use air that we blow in to help the process. The tanks are normally filled with concentrates that are produced either from a mining operation, or from refloating tailings. The concentrates contain all of the metals that we're after, which will pay for our environmental cleanup.

We have two current projects we're working on, one is in Bolivia, which is in a partnership with the national mining company called COMIBOL, and oddly enough is not a bioleach candidate.

This is a simple gravity flotation circuit, reprocessing tailings, very high grade tailings, that should lead to cash flow later this year, that's really the importance of that project is to get the cash flow. The metals that we're after are very high grade silver, the tailings run just under 9 ounces of silver per ton, people say why, and it's because they used to mine 300 ounces a ton, and by losing 9 ounces they were only losing 3% dilution.

There was also never any recovery of the copper, the copper runs about 2.25%, which is mine grade, then finally we've discovered that the tailings look like they contain about 1.5% tin. I only bring that up because tin recently just went through twenty thousand dollars a ton, and effectively will be the largest metal content in that pile.

We're drilling them right now on a 20 x 20 meter grid, those results will started to come out mid-February, and will continue for the next, probably 30 to 40 days, we're drilling a total of 60 holes. The reason is the tailings are from several different mines. One mine was mining tin, one was doing silver, and at various times, depending on the prices of the metals at the time, the depositions of these tailings were pretty arbitrary. We want to know where the metal is in the tailings, so we can mine it effectively, and get our capital back as soon as possible.

The other project is something we started looking into in Ecuador, and it's basically being the back end processor for the artisanal miners, the artisanal miners today are using mercury, on the rock that they're mining, and the pollution is just off the scale, not to mention the loss of life that occurs, from being exposed to mercury gasses over a number of years. A lot of these people unfortunately, are dead by the time they're 40.

What we're trying to do is say look, stop delivering rock covered in mercury, we'll buy it from you, crush it, float it, and then we'll do the processing ourselves. What we're doing is we're replacing the Chinese miner, who is now buying this product for roughly fifty cents on the dollar and taking it back to China. So we're going to provide an on-site answer to this problem. We are going to mitigate, arsenic contamination, as well as mercury contamination.

Dr. Allen Alper: That sounds very good. Could you tell me a bit about you and your team?

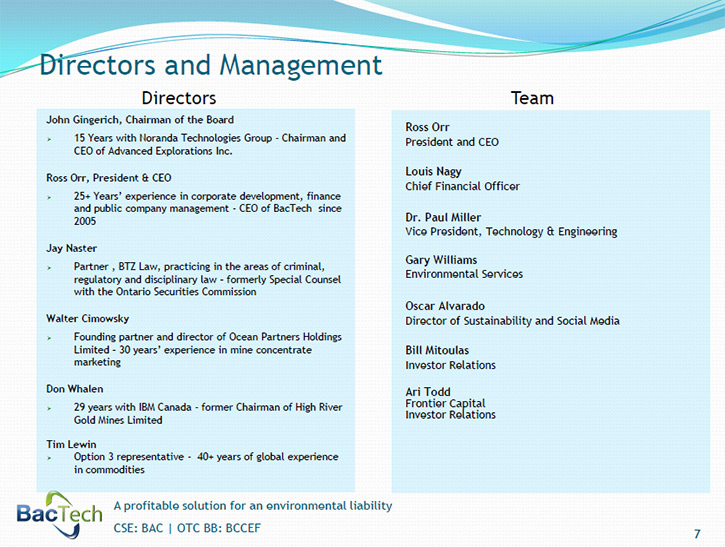

Mr. Ross Orr: Sure, my background is originally in the securities business, with the largest company in the country, up here in Canada called RBC Dominion Securities, but I've effectively been in the resource sector since, probably the early nineties, mostly on the side of financing and entrepreneurial nature. Although I did bring this company from Australia to Canada, back in 1995 and helped with the original listing of the company, and effectively, took control of this company when I split it in half, back in 2011 into a mineral processing company, and an environmental company.

Our Chairman is John Gingerich, from Noranda and Chairman and CEO of Advanced Explorations Inc. Other interesting people on our board Walter Cimowsky, who is a partner in Ocean Partners, a metal trading concentrate company, a natural fit for us. Jay Naster, used to be the head prosecutor for the Ontario Securities Commission, and also was the head prosecutor of the Bre-X trial, you remember that Al, from many years ago.

Dr. Allen Alper: Yes.

Mr. Ross Orr: Then we have Don Whalen, who was the Chairman of High River Gold, for 16 years before it was bought out. We have Tim Lewin, who is from London, England, and represents our largest shareholder over there, and then John Gingerich, who was a former head of technology in Noranda, nuclear physicist I think by training. Dr. Paul Miller stirs the drink. He is the bioleach expert, and oddly enough, he's based in Perth, Australia, but that isn't an issue with today's communications.

Dr. Allen Alper: That sounds like a very strong team. Could you tell me a bit more about your plans for 2017?

Mr. Ross Orr: We're drilling right now, I believe as of the weekend we are up to about thirty of the sixty holes that we're drilling, and remember you're drilling 10 to 12 meter holes here so 30 - 35 foot holes, and the material of course, has already been crushed, and ground before, so in essence the actual drilling process, is quite inexpensive, as well as quite quick.

The results of all of these 60 holes will be assayed and published, and then we'll move on to the metallurgy or how do we recover the metal that's in this half a million tons of tailings? That should be done by mid-year, then assuming we can get economic recovery grades, we should be designing and building a simple gravity flotation plant that should be done by the end of the year.

Hopefully we are starting to produce metal by the last quarter of this year.

I'm probably heading down to Ecuador in about 10 days again, to meet with the government, and to look for a local partner. I don't really ever want to own 100% of anything in these countries, because I don't know the rules, I don't speak the language etc. It's good to have somebody local who's going to fight your battles for you.

In the near future we're going to collect about 200 kilograms of material, from these existing flotation plants and ship it up here to Canada, to Laurentian University, where we'll do probably five to six months of bioleach work. Once we have finished that, and we're assuming that it's going to be positive, we would then start the engineering design, and probably sometime in 2018 build the plant.

These are scaled down versions of what we've built in the past, most of the ones we've done before have been 100 tons a day of concentrate, these will be 40 tons a day, but they'll be a number of them in various locations in Columbia, Ecuador, Peru, and maybe even into Central America, depending on the need, or the problems again with these artisanal miners. So it's a bit of a different angle for us, it keeps the capital cost down to 10 million, and your payback is probably a year on this.

Dr. Allen Alper: That sounds very good. Could you tell me a little bit about your financing, and your capital structure?

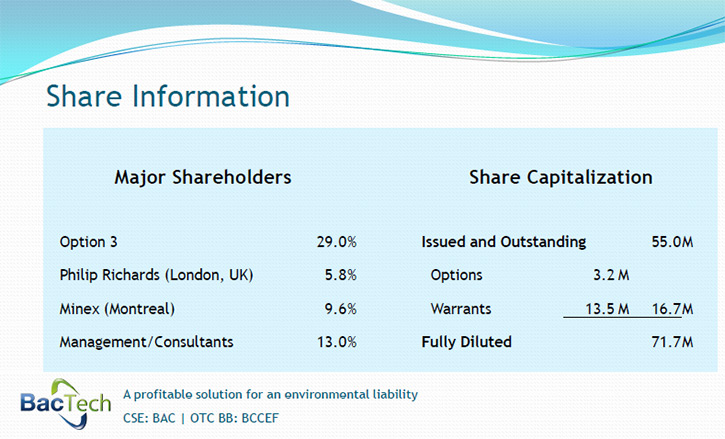

Mr. Ross Orr: Sure, we have as of today approximately 58 million shares outstanding, the stock trades around six cents, which I'm happy to say is up about 300% over the last year, but I really think we're just getting going now. We raised some money just recently a couple of hundred thousand dollars, we're trying to keep the dilution to a minimum, and just raise enough money, to get us to that next step.

That's basically it, we have warrants outstanding that are 10-cents, that range anywhere between one and two years in term, mostly as a result of these small financing's, we've been doing over the last year or so.

Dr. Allen Alper: That sounds good. Could you tell us your vision?

Mr. Ross Orr: Well, I guess I want to be one of the first green companies to make money. I say that tongue in cheek. Most of the solar companies live on government subsidies, they need fifty cents a Kilowatt hour to make money. We don't do that. We don't rely on the government for anything. We want to build a company that is going to be a collection of bioleach projects that run through South America, Central America, and making money, each plant producing in the neighborhood of 25-30 thousand ounces a year, with margins that are predominately 40%. That's by buying, processing, and then selling off a doré bar at the back end.

Dr. Allen Alper: That sounds great. By the way I have a connection with refineries that will buy your doré bars at some point and be willing to help finance you.

Mr. Ross Orr: Oh, I'm definitely interested in that. I like that news.

Dr. Allen Alper: Anyway, you should keep that in mind.

Mr. Ross Orr: Oh, I will.

Dr. Allen Alper: I‘m very impressed with your company. What are the primary reasons our high-net-worth readers/investors should consider investing in BacTech Environmental Corporation?

Mr. Ross Orr: Well, I would say that for starters, we're a ridiculously low market cap, for a company that should be producing cash flow later this year. Now our deal with the Bolivian's, and with the government, is one of twenty-six projects they had for us to look at. There is no shortage of projects out there for us. One of our key differences is that we take the risk out of everything, by not having to drill blind holes in the ground, develop a resource, drill 15,000 meters, of hard rock drilling.

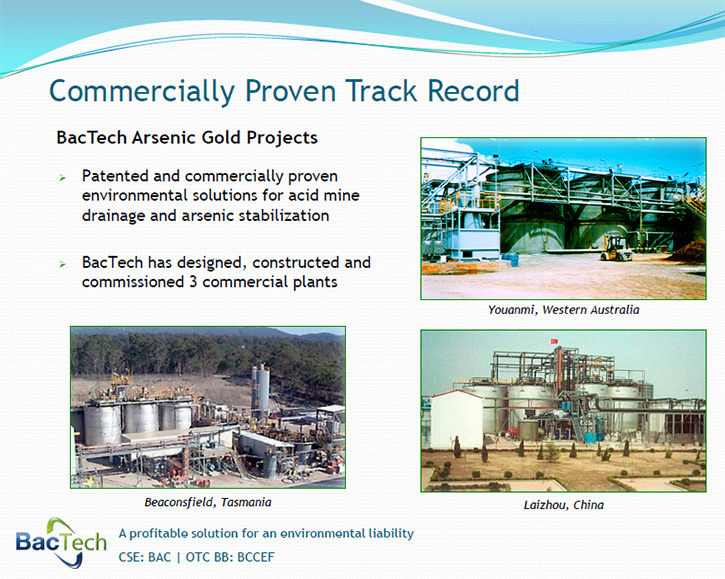

Everything that we have is sitting on surface, and effectively you're drilling sand, so it's a very low cost, low risk way, to participate in resource extraction. But with the added kicker being, that we're doing something green at the same time. Bioleaching is not a new technology for us, the first plant we built was in 1997, in Australia.

Dr. Allen Alper: Would you like to tell our readers about some of the plants you've run, to give our readers a more complete background.

Mr. Ross Orr: The key, in mining technologies, is commercialization. It takes a longtime for the mining industry to accept a new technology, to get the confidence of the people in the industry. We built our first plant back in '97 in Australia, we built another one in China in 2001, which we subsequently doubled in size in 2008, and then we also built one in Australia, in Tasmania in '97 that ran for 15 years, processing high arsenic gold concentrates.

Bioleaching works, Gold Fields has built over twenty plants. They are not competitive with us because we're on the environmental side. That's the key. Unless you have something up and running, you are just one of many with unproven ideas.

Dr. Allen Alper: That sounds good. Is there anything you'd like to add Ross?

Mr. Ross Orr: No I would just say it's been a long haul getting to where we are, we've known each other for a long time Al right. We’ve worked steadily, never giving up. hopefully we've found the right niche for this technology, low capital, higher stake projects, that really nobody else wants, so you tend to own the market to yourself, at least in the near term. So I think we're a great buy.

Dr. Allen Alper: That sounds great.

http://www.bactechgreen.com/

BacTech Environmental Corporation

PO Box 2029, Suite 1820

20 Eglinton Avenue W.

Toronto, Ontario M4R 1K8

Canada

Phone: (416) 813-0303

Email for all inquiries: borr@bactechgreen.com

|

|