Interview with Mr. Per, Thorsell, CEO of ProfilGruppen AB.: a Swedish Company that Markets, Develops and Manufactures Customized Aluminum Extrusions and Components.

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 9/15/2016

ProfilGruppen (Stockholm: PROFB) is a Swedish company that markets, develops and manufactures customized aluminum extrusions and components. The

company's vision is to be the preferred supplier of innovative aluminum extrusion solutions in northern Europe. We learned from Per Thorsell, CEO of

ProfilGruppen AB, that aluminum is the third most common element in the earth’s crust after oxygen and silicon. It is a light-weight, strong, ductile and

durable material that requires zero maintenance, and is therefore the perfect choice for use in a variety of construction contexts. It has good recycling

properties, thus a low environmental impact. Its high resistance to corrosion and ability to withstand the elements mean that it can be used in an

unlimited range of areas. The customers of ProfilGruppen belong to such areas as Automotive, Electronics, Interior design, and Industry and Construction.

According to Mr. Thorsell, aluminum is the material of the future.

Dr. Allen Alper: This is Dr. Allen Alper, Editor-in-chief of Metals News, interviewing Mr. Per, Thorsell, CEO of ProfilGruppen AB. Could you tell

me a bit about your company and what products it makes? I know it's an aluminum extrusion company, and you only produce products that are requested by

your costumers?

Mr. Per Thorsell: ProfilGruppen is a Swedish company that markets, develops and manufactures customized aluminum extrusions and components.

We don't have our own products. Everything we make starts with requests for what the customer needs for their products, for their applications and

machines. By delivering innovative solutions in aluminum for our customer’ needs, we are contributing to our customers’ success. One of the core elements

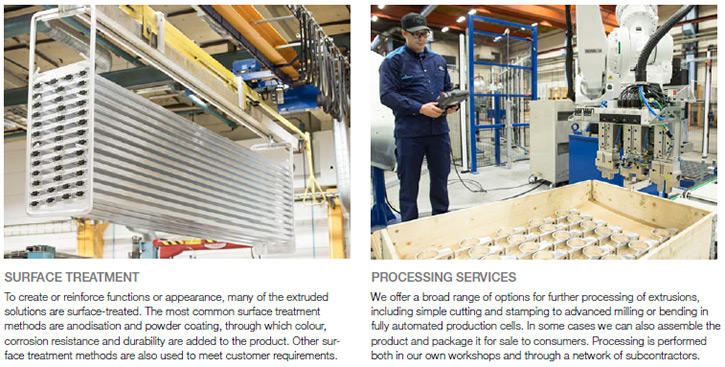

of our business is finishing and refining aluminum extrusions. Using in-house and out of house resources, we provide a range of advance refinement

services such as cutting, processing, welding, bending, surface treatment and assembly.

We work to a structured and well-defined model in order to ensure that your extrusion or component is brought to optimal levels. Contact us when your

product is at the conceptual stage, and we’ll do everything we can to help you get as close as possible to your requirements.

There are all kinds of products depending on the customer. If a customer needs something constructed in aluminum, we are able to do that for the customer.

We're trying to add more to the product and the scope for the customer; so we can do the final product and packaging for the customer and user.

We are working with one of the world’s greatest materials, aluminum, the material of the future. Aluminum is the third most common element in the earth’s

crust after oxygen and silicon. It is light-weight, has good strength and good durability. It has excellent corrosion resistance and is easy to use,

particularly in a construction environment. It has good recycling properties thus a low environmental impact.

Our head office is located in Åseda, Sweden, which is where our activities first started more than 35 years ago. We are characterized by quality

awareness, efficiency, and customer focus. The Group currently has around 350 employees and we operate primarily in the Northern European market. About

50% of the things we sell are to Northern Europe: Germany, Finland, Norway and Denmark, so Scandinavian counties, the northern part of Europe, the U. K.

and those areas.

Dr. Allen Alper: Could you tell our readers about the types of customers and industries you serve.

Mr. Per Thorsell: Our customers are quite evenly spread in all segments:

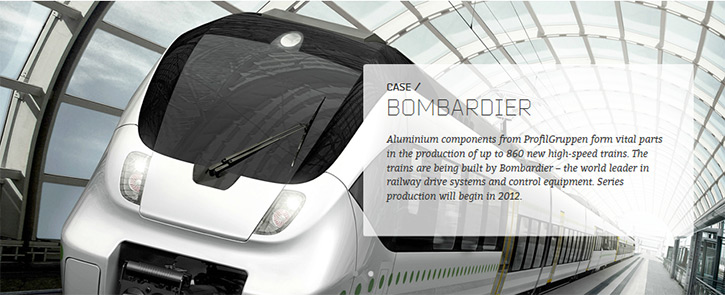

Automotive, Electronics, Interior design, and Industry and Construction.Trains

ProfilGruppen, in close collaboration with Bombardier, has developed 13 complex aluminum components. The components make up the frames of four different

types of electronics cabinets for the new train series. They are part of the train’s structure and contain all the necessary electronics. They meet

stringent requirements. The trains and cabinets must withstand stresses and strains for at least 40 years! Bombardier will now get a more complex product

than in the past, with extrusions, friction stir welding and processed components. “ProfilGruppen has a good mix of expertise. The company offers turnkey

solutions, is attentive, enjoys a high level of expertise yet also remains competitive, price-wise. Collaboration between Bombardier’s and ProfilGruppen’s

designers also works very well,” says Bombardier Transportation in Västerås. ProfilGruppen’s product is light, strong and cost effective.Telecoms/Electronics/Power Generation Industry

Aluminum is a very good conductor of electricity and heat in all types of electronic and telecommunications equipment. Where there are stringent

requirements on conductive and cooling abilities, low weights, minimal volumes and durability, aluminum extrusions are the obvious choice.

We have developed many solutions where the ability of aluminum to conduct heat and electricity has been exploited in applications for the

telecoms/electronics/power generation industry. Our unique Alutin surface treatment method enables us to make the surface of our extrusions

electrically conductible, solving the problem of grounding in electronic units with an aluminum casing. As an expert in aluminum, we have long been

a partner to many companies in the electronic industry.

When ABB needed new cooling extrusions, they turned to ProfilGruppen. We produced extrusions that had a considerably smaller surface whilst still

retaining the required cooling characteristics. In addition, the new solution was cost-effective thanks to the use of a simpler production process.

Interior design

We are an important partner to the furnishing industry. Aluminum is light, strong and highly ductile. Its flexibility and durable surface opens the

door on a whole host of design possibilities for structures of various types. Surface-treated aluminum requires minimal maintenance and retains its

newness year after year.

Jan Hultinsson, Design Engineer at ProfilGruppen, when asked, what challenges did the project present?

“It was primarily a combination of high standards regarding form, function and aesthetics. For me it was the necessity of entering the design work as

early as possible to be able to deliver high quality in both of these areas.” (Good advice for all potential customers.)

We build for the future

Aluminum is a strong, ductile and durable material that requires zero maintenance, and is therefore the perfect choice for use in a variety

of construction contexts. Its high resistance to corrosion and ability to withstand the elements mean that it can be used in an unlimited range of areas.

Our customized extrusions are used in everything from doors, windows and balconies to patient lifts and wheelchairs.

Dr. Allen Alper: Would you like to describe your production process?

Mr. Per Thorsell: We buy aluminum like logs, heat them up and extrude them in three different presses. From there we make different

profiles. They can be used outside in more aggressive environments, stored safely to help the final product. Processing is performed partly in-house and

partly by a network of external suppliers. The production facilities for manufacture and processing of aluminum extrusions are modern and cost-effective,

and offer high productivity.

Dr. Allen Alper: Could you tell me what differentiates your company from other companies?

Mr. Per Thorsell: We really focus on understanding the needs of our customers and what they require. We may make some changes that

can improve the product for the customer. We produce it in a cost effective way. We try to respond to the customer and make services around their needs.

Other than extrusion and manufacturing, we really, really try to understand the customers’ needs, be cost effective and give the best service to our

customers. We are on the customer’s side, we serve them in a good way, which is why we are growing successfully.

Dr. Allen Alper: Wow that sounds very good. Tell us about you, your staff, your manufacturing facilities, your operations?

Mr. Per Thorsell: I've been with the company for two and a half years. Before this I worked half of my life in marketing and half in

production and supply. It was a very good combination to get a good understanding of a customers’ needs.

Our staff is one of our success stories. We have a lot of people who have been in the company for 20-25 years and really understand and know the

process. From extrusion to manufacturing and production and construction, the combination of experience and knowledge really shows. They can speak

to each other and to the customer and make it more cost competitive or give the best price to the customer and maybe even change his design. We can always

do that in the extrusion process or to make it a bit cheaper or a bit cost competitive. That's actually how we respond in our whole organization, in that

perspective, it's great to have all the experience in the production and process side of the company. We have 350 people in the Southern part of Sweden.

We have approximately 50% of the manufacturing in our own workshops and 50% of manufacturing is done in local companies surrounding our company.

In the last year we built a line where we build furniture for the decoration industry. We make consumer products in our new plant where we do extrusion

profiles. Then they go to another place where we finish and dry and package them for the consumer in one complete line.

Dr. Allen Alper: That's very good. Could you tell me the main reasons why investors should invest in your company?

Mr. Per Thorsell: I think we have had good development in the last two years, focusing on customer needs and transforming our process and

showing that we can be very profitable for our customers. If you take the Swedish market, we have done 15-22% more shares and 18,000 calls. There is a

good market for our service. Our industry is growing in a good way. There's great growth potential in our markets. I expect we’ll be very profitable.

ProfilGruppen is a profitable company. Our sensitivity to economic trends is moderated by the fact that our customers are from several different

industries and operate in different markets, our product mix contains products with a varying degree of processing.

We have a generous dividend policy, which produces annual dividends. Our overall aim is to give our shareholders a high total yield, partly through

share dividends and partly through increased share value. Our dividend policy is to distribute 40-50 per cent of the profit after tax calculated over an

economic cycle.

Dr. Allen Alper: That sounds very good indeed.

http://www.profilgruppen.se/?lang=en

Head of Sales and Marketing

Per Owe Isacson

Tel: +46 474 551 60

Mobile: +46 70 349 57 60

E-mail: po.isacson@profilgruppen.se

ProfilGruppen Extrusions AB

Box 36

SE-364 21 Åseda

Visiting address: Östra Industriområdet, SE-364 31 Åseda

Tel: +46 474-550 00

Fax: +46 474-711 28

E-mail: info@profilgruppen.se

|

|