Interview with Major General David R. Heinz, President and CEO of IBC Advanced Alloys Corp. (TSX-V: IB, OTCQB: IAALF): Leading Manufacturer and Supplier of High-Performance Beryllium Aluminum Cast Components and Specialty Copper and Other Alloys

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 9/3/2016

|

IBC Advanced Alloys Corp. (TSX-V:IB, OTCQB:IAALF) is a leading manufacturer and supplier of high-performance beryllium-aluminum cast components and

specialty copper and other alloys. The Company serves customers in a variety of industries such as defense, aerospace, automotive, oil & gas, electronics,

and telecommunications. The company is under the strong leadership of highly decorated Major General David “Duncan” R. Heinz, who serves as President and

CEO. The company has two business divisions: - the Copper Alloys Division and the Engineered Materials Division, and serves its customers from four

manufacturing locations in the United States. IBC Advanced Alloys recently raised C$7.46 million in an over-subscribed, non-brokered placement that they

are now using to upgrade and optimize equipment, increasing throughput capacity, and further reduce cost. IBC Advanced Alloys Corp. also is at the

forefront of developing scandium-containing aluminum alloys. General Heinz stressed the importance of IBC’s relationship with NioCorp Developments Ltd. –

which intends to produce Scandium in the U.S. -- and the importance of scandium-containing aluminum alloys in the aerospace industry to significantly

reduce aircraft weight, improve fuel efficiency, reduce emissions, and strengthen performance.

|

Dr. Allen Alper: This is Dr. Allen Alper, Editor-in-Chief of Metals News, interviewing General Heinz, who is President and CEO of IBC Advanced

Alloys. General, could you tell our readers/investors about your Company, your products, and the markets you serve?

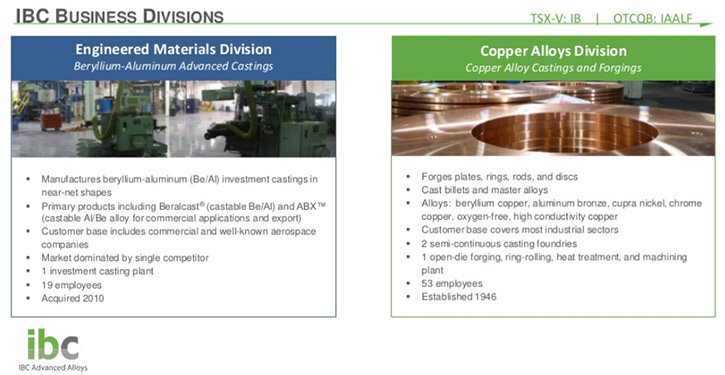

General Heinz: Well, IBC Advanced Alloys has two different divisions with four manufacturing facilities, all located here in the United States. The

biggest is the Copper Alloys Division. Their primary facility is in Franklin, Indiana, with about forty-five employees, and they specialize in copper

alloy production. That facility really is a metal services company in that it creates the metals, the billet form, the rod form, or the block form of

specialty alloys, as well as semi-finished and finished products.

To get to the semi-finished products, they have a number of different capabilities, from annealing to rolling to hammering to forging the

materials into the semi-finished and finished products. We do a significant amount of the machining work on our own to be able to produce those products,

and we sell to a number of different companies, including those in the automotive and electronic industries. It is all about the individual properties of

the alloys that allow our customers to achieve greater strength, conductivity, higher resistance to heat expansion or contraction, and other properties.

Depending on the end use of the product, we very much focus on the chemistry of the alloy as well as getting to a near net shape for the final

product the customer is looking for. They also have two specialized milling operations, one in Royersford, Pennsylvania and one in New Madrid, Missouri.

We keep a small cadre of folks at those facilities, and those are both specialty mills that are designed to create some of the very difficult-to-alloy

materials. That’s the Copper Division.

General Heinz: The other division is our Engineered Materials Division, which operates out of Wilmington, Massachusetts. We have about twenty employees

there, and they specialize in the ability to cast very advanced materials – beryllium-aluminum in particular. Beryllium-aluminum is a very difficult

alloy because of the extreme differences in the melting temperatures of the two elements. Our ability to get the metal in a cast-able form, and then have

the desired crystal structure and the homogeneous nature of the metal itself – that’s tough to do. Our team in Wilmington has the secret sauce, so to

speak, on this process, and we are currently producing parts for both aerospace and commercial electronics manufacturing companies from that plant.

Dr. Allen Alper: That sounds very good. I understand you stress environmental and health and safety.

General Heinz: We very much do. About six percent of the general population has some kind of sensitivity to beryllium, so every employee who works around

the material has an initial blood test to test for that sensitivity. We do complete physicals, and we make sure that those who are required to wear

respirators do so, and that we take care to follow all special handling rules and procedures. There are shower facilities available so our workers can

shower before they go home. We provide protective clothing and gear for them as needed, et cetera. We're very particular about all of this. We want people

to feel comfortable working around the metal, and we've had no issues in terms of any sensitivities with current employees.

Dr. Allen Alper: I heard that recently you had a finance placement aimed at increasing the capacity of your manufacturing processes, and that the

raise was over-subscribed. Could you tell me how that's coming and the timetable?

General Heinz: We raised $7.46 million in Canadian dollars. That's equivalent to about 5.5 million after fees. We'll have roughly five million of that

for all the US operations, so ninety percent of that funding is going directly into our production facilities. We'll use it either in working capital or

for capital expenses. When I say working capital, though, I'm not talking about just putting it into the checking account to spend the money. We have

focused on using it in places where we can secure improves in efficiencies and production capacity. Let me talk to each division separately.

The amount of money going to each division is approximately equal. With regard to our Copper Alloys Division, we focused on the brutal reality

that sales have been decreasing over the last few years. But when we looked into the reason, we found that the orders, in terms of people making requests,

hadn’t decreased appreciably. It's just that we weren't winning as many orders. After investigating why, we saw two key trends.

One is that as companies were reducing inventories, they were changing their fulfillment dates, because they didn't want to carry the inventory

themselves. So, one of the adjustments we are making is to better meet our customers’ fulfillment dates so we'll win more orders. So we’re using some of

the proceeds both in inventory control of the actual metals available, and having certain alloys already mixed and available in certain forms so that we

can go directly into the semi-finished and finished processing.

The second thing we saw going on was that we were losing orders because we didn't have the equipment necessary to meet customers’ specifications.

For example, we weren't maintaining oven temperatures at the proper tolerance levels. We've made several changes that will allow us to compete more

advantageously and to produce metals that we know customers want, so that we can bring both the top line for the copper division back up, as well as

reduce some of the cost structure. That's predominantly where the working capital on Copper is going to be spent.

Dr. Allen Alper: That sounds excellent.

General Heinz: On the Engineered Materials Division side, we really wanted to focus on the two sides of this. We know that the orders are there. We know

a number of aerospace companies want us to create product for them. So, it really all became about our ability to produce at rate. When you look at rate,

you want to focus on what your constraints are. What are the places where adding capacity makes sense? We've been examining our processes through

constraint theory on two sides of that. For example, by automating the process, by changing the way we produce, can we save time and money?

Those are the first changes we are making. We also are looking at what we are doing today that is either outsourced or done internally, but by

manual means. We are seeing if we can improve those processes by shortening the time and, therefore, reducing the cost.

The second is on addressing other constraints. Once you've solved melting capacity, for example, then you have to take a look at all of the things that

feed into that. Much of the funding we are doing is to improve those constraints so we can literally double the throughput capacity of EMC over the next

twelve months. That's exactly what we're focused on.

Dr. Allen Alper: That sounds excellent. I hear some of the products you're making are actually being used on some of the planes that you used to

fly. Is that correct?

General Heinz: Well, the current product that we are building is for the F-35 Joint Strike Fighter. I never personally got to fly the F-35. I was the

Programming Executive Officer for the F-35 on the government side. I did a lot of work relative to the simulation work for the program. I understand the

requirements of this platform very, very well. I've been with the F-35 program all the way back to my days with Marine Corps Headquarters when I worked in

Aviation Requirements. The F-35 is really an exciting airplane. And, my son has recently been selected to fly the F-35. He's currently an F-18 pilot

today.

The component we're building for F-35 is part of the Electro-Optical Targeting System, known as EOTS. The glass structure that you see on the

nose of the aircraft is what houses EOTS. The sensor in that system has to be put down into that glass structure so the housing that actually brings the

optical array down into that glass structure is the assembly that we make. The reason why Lockheed Martin has chosen the beryllium-aluminum material is

because beryllium-aluminum provides a tremendous resistance to modulus, i.e. vibratory modes. Let me explain.

In the aircraft, you have a number of different vibratory modes -- some created by the engines, some created by the acoustic noise that comes across the

nose of the aircraft, and others. If you're looking through a very long range optical system, the last thing you want is vibration. We call that jitter.

The beryllium-aluminum alloy that we make and cast is designed to essentially isolate the electronics that are mounted on it from all of the rest of those

vibrations that occur. It helps to minimize jitter, and it does so extremely well. It’s one of the reasons why that sensor system on the F-35 is so

good. It greatly dampens vibratory noise, which allows for a 7X increase in standoff distance for weapons acquisition and release.

The modulus of beryllium aluminum is four times greater than titanium. That's the reason they use it. The traditional way of making this part is

to start with a single block of beryllium-aluminum. They then have CNC machines hog out that housing assembly. It takes them a very long time to do that,

the lead times can be extreme, and it is very expensive. Now, by having IBC precision cast that piece in our facility, we've reduced the waste, we've

substantially reduced the cost of the product, and we’ve kept the same quality. Lockheed is very excited about that. They understand our approach helps

them and taxpayers achieve better cost reduction with the system. In fact, it's one of their more significant initiatives for reducing the cost of the

aircraft, and we're excited to be able to deliver it to them.

Dr. Allen Alper: That sounds excellent. That's really a great accomplishment. Could you tell me a little bit more about your background and your

team's background?

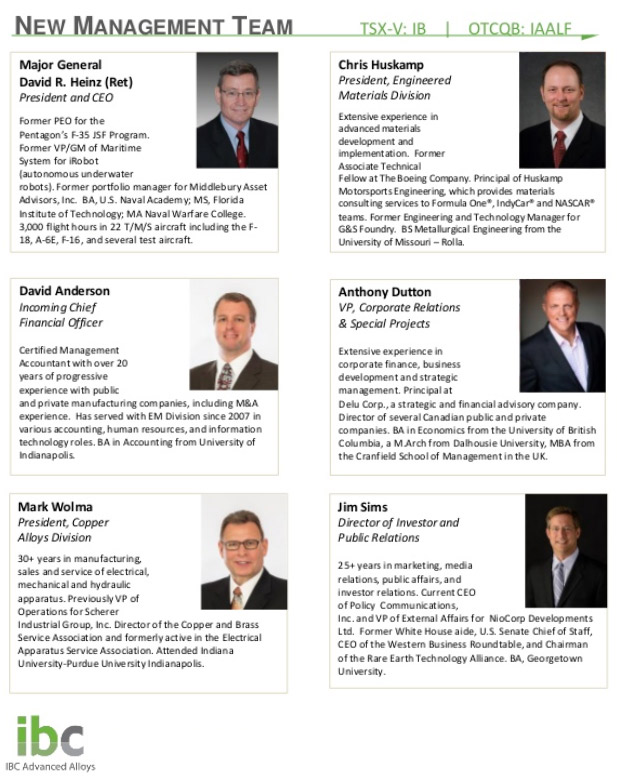

General Heinz: I spent 32 years in the military as a Marine aviator. I was a US Navy test pilot graduate, a distinguished graduate, and I spent four

years in the test pilot community. Then, I did a transition to flying F-18s. I served the F-18 community through several tours and then moved to

Headquarters Marine Corps where I worked in Aviation Requirements. Then, I went back into aviation where I ran several programs as an acquisition

professional. I went down to run the Advanced Tactical Aerial Reconnaissance System, called ATARS, for the F-18.

I was then the C-130 program manager for the Marine Corps. The C-130J was one of our products. I was also the AV-8B Harrier ‘Jump Jet’ program

manager for three years before being selected as the Marine Corps' first dedicated acquisition General.

I spent four years as an acquisition General, primarily taking a look at how we can improve building a professional corps of acquisitions people within

the military.

The Commandant of the Marine Corps' job is not only to train, it's to equip Marines, and we needed a force that understood how to solve the

challenge of getting from the initial requirement to end of life of product in a manner that doesn't continue to drive up cost. We needed people within

the Marine Corps who were specialists in acquisitions. So, what we did was to take regular Marines who have served a complete service tour -- and several

of them, like me, had more than that – and we indoctrinate them in contracting, in acquisitions, in how to do requirements generation, in how to do risk

management. Then, we introduce them into the acquisitions cycle. Eventually, some of those folks become people like me, who actually run entire programs.

All the armed services take this approach now. The Navy and Marine Corps as well as the Air Force all have acquisition professionals. I was very

proud of that, and that's what led to my selection as the deputy and then the General for F-35 Joint Strike Fighter. After that, I spent more than six

years in the business sector. I worked with a robotics company for several years. I've worked with a technology company as their Chief Operating Officer.

When I started with IBC, I was the Company’s COO, and then I took over as the President and CEO in May of this year.

Dr. Allen Alper: Well, that's a very, very impressive, outstanding career, and I understand you're highly decorated, too.

General Heinz: Those are kind words. I'm sure that there are others who are more decorated. But I do have air medals, I have Navy Achievement, Navy

Commendation, Defense Superior Service medals. There is a place where you can look up that type of information within the Marine Corps under retired

general officers, so my bio for my Marine Corps and what tours I did are available.

Dr. Allen Alper: Thank you. I must thank you for the service you've done for the country. We need officers and people who are willing to do that

and have done such a great job. It helps make the United States strong and has kept us safe, so I really appreciate that.

General Heinz: Thank you for saying that. I will tell you that the men and women of the armed services very much appreciate that type of recognition.

There was a time when that type of recognition was not so strong from the public, and military veterans didn't feel as appreciated as they do today. But

that simple thanks goes a really long way. These selfless men and women are the reason why I stayed in the service so long, because they are just a joy to

work with. If you have a son or a daughter in the service, or you know someone who has, thank them for that service. They're the ones that helped keep me

in service that long.

Dr. Allen Alper: You must be very happy and proud that your son is doing so well and went into the services and is accomplishing so much.

General Heinz: Well, I'm extremely proud of him. He went down to Clemson on an Air Force scholarship and then at the end of the third year he came to me

and said, "Dad, I can't be an Air Force officer." I said, "Not a problem. Let's figure it out." Very shortly after that he told me he was talking to the

Marine recruiter, and that he had decided to sign up for the Marine program. I just simply asked him two things: One, you're not doing this for me, right?

And two, you understand being the son of a general officer is different? He completely understood that, and what I will tell you is that he has earned

everything he's got. He is a great son who understands the Marine Corps leadership, has grown up around it, loves what he does, and is very, very good at

it.

Dr. Allen Alper: That's excellent. That's really a great accomplishment, not only have you an outstanding career but you now could be very proud of

your son's accomplishments. That's wonderful. Could you tell me a little bit more about your board?

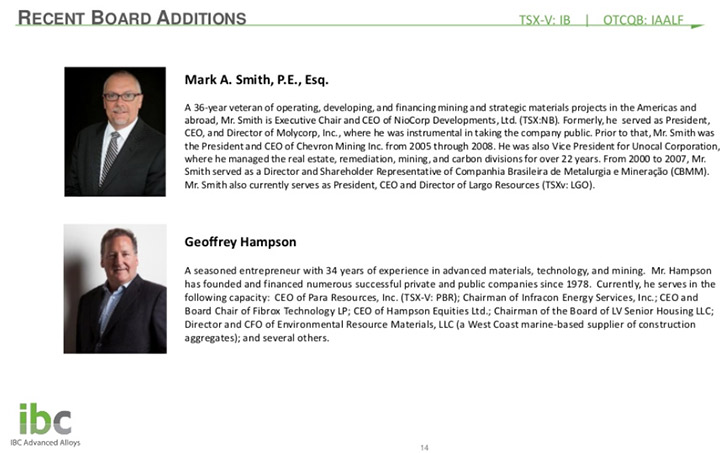

General Heinz: Sure. We have added two new board members. Mark Smith is CEO of NioCorp Developments Ltd. As you know, we have a joint development program

with NioCorp under which we are taking a look at development of scandium-doped alloys for the future. I'm very excited about that in terms of its promise.

What I will tell you, though, is again, these are two separate companies that are enjoying the integration and alignment that we get with an exploration

type company like NioCorp all the way to an end product company like IBC. The synergy that these two companies can provide each other is very exciting.

Mark Smith is an extremely accomplished businessman, has great instincts, and I very much enjoy the discussions that he and I have in terms of how we grow

this company and what are the future opportunities at IBC.

Geoff Hampson also recently joined our Board, and he has great business acumen as well. He has run a number of different companies, and he has

great expertise in metallurgy and in metal products and manufacturing. We rely on him to truly help us better understand the marketplace, market

opportunities, as well as financial issues. They have given us two great additions to the Board.

Mike Jarvis, an entrepreneur and great individual in his own right, also serves on our Board. He runs Jarvis Enterprises, but previously he worked

for and ran several manufacturing companies with upwards of three billion dollars in annual revenues in Indiana, before they were sold out to larger

companies. Mike is extremely gifted on the financial side. He's always asking the right questions in terms of what are we doing to improve our cost

structure and improve our market positioning.

Finally, Anthony Dutton serves on our Board. He was the former CEO. He's still contributing to help us grow this company.

Dr. Allen Alper: That sounds like you have a very strong board and an experienced board. That's good. Could you tell me a little bit about your

capital structure?

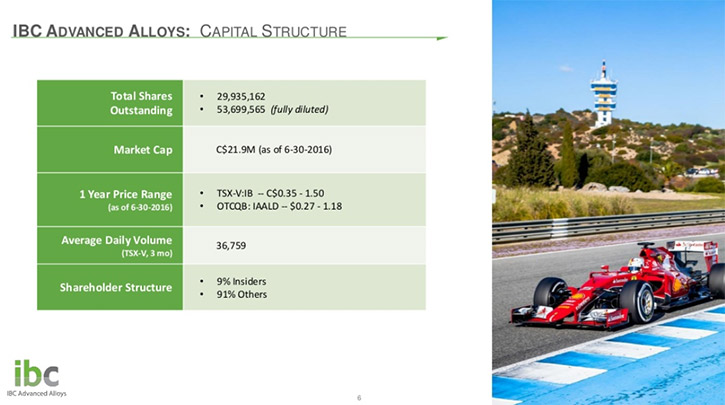

General Heinz: Sure. We are listed on the Venture Exchange in Canada. The symbol is IB on the exchange and there are approximately twenty-nine point six

million shares issued right now and outstanding. The share price, I believe, at close yesterday was seventy-five cents, so that would put us in the market

cap of around $22 million Canadian.

We also have a U.S. listed symbol. It's IAALF. We will very soon upgrade the CUSIP on that to make it easier to trade that symbol here and then we

will sell the shares in the Unites States. If you go in to the buy in, you'll see it's very low. It's because they CUSIP itself is just not very friendly

to having it owned by U.S. investors. As we have improved the diversity of our investor base, moving beyond Canadian investors, we now have a significant

number of European as well as U.S. investors. We're still 67 percent owned by Canadian investors, but those Canadian investors only represent twenty-six

percent of our base. I believe, as we continue to grow, the company will expand the number of shares that are issued outside of Canada and continue to

grow the company that way.

Dr. Allen Alper: That sounds excellent. Could you give me the primary reasons why our high-net- worth investors should invest in your company?

General Heinz: I believe we have developed a very important technology that is only now starting to really ramp-up in sales. We've spent several years on

the beryllium-aluminum alloy side of our business perfecting that technology and getting the certifications within the aerospace industry so that we'd be

able to sell those products. Now, crossing that hurdle and being able to qualify both the material and the process took us a very long time. But we've

now completed that certification and it's no longer about whether or not the metal meets the requirement. We know now that is does. We have a

specification showing what a cast-able metal looks like and how the different forms can take shape. Any engineer within a major aerospace company can now

read about that specification and understand how they would apply it to either a current design or a future design.

Now it's all about what I call getting into the specific application. A company now says, "This is what we want to be able to do with the product. Can we

create this part? Two, we want to be able to test that first creation in a form-fit-function type of capability.” Very shortly after you finished the form

and functions, then they want to know the rate of production. Can you continue to produce those products for us at low rates so that we can test the

quality at the scene where the capability is very good? Then, very soon after that, can you move to high rate production?

For our EMC division in particular, we don't want to continue going through this time-consuming process with every other aerospace company. So,

our goal is to find the parts that are using beryllium aluminum now, or in the very near future, and which represent a potential for supporting the

production of thousands of parts over a twelve to eighteen month run. We don’t want to be a job shop for only hundreds of parts at a time. Fortunately,

we have found several of these opportunities. We are going through the process with those companies now in terms of producing those first form-fit-

function components, and we believe very soon we'll be able to announce that we're moving to the next step of low-rate production with those companies.

We've already told you the BAE Systems, which is a major global defense contractor, is one of them. I will tell you there are two other aerospace

companies that right now don't want to be identified specifically, because one, they want to know that the product works and two, they don't want other

competitors to know that they are actually considering our material and our capabilities with this material to reduce their cost.

On the Copper side, I am equally excited about the capability. Copper has been through a very tough time. Now, just looking at the copper price --

In 2014, copper prices were at $3.50. Prices bottomed in January at $1.96 and I think they are in the range of about $2.20 now. We've been up to $2.32,

we've been down to $2.06. It has been a volatile pricing environment recently. However, copper is slowly starting to pull out of this. We see things in

the oil and gas sector starting to do the same thing. Oil prices have now come up from their lows. The stock market is starting to show some stability. We

see rig counts starting to increase again. Inventory levels are starting to show and the consumer is getting a great advantage in lower gas prices and is

taking advantage of that by traveling more. I'm exciting about the potential where oil and gas could be a year from now. We make a number of different

products, both in the copper alloy side and in the beryllium-aluminum side that will support that industry.

Can we get this company to profitability in the next twelve months? I believe the answer to that is absolutely yes. Two, can we start getting on a

ramp-up of increasing our sales and increasing revenues to make it more profitable for investors. The answer is yes, and I believe that very strongly. In

fact, I am taking my compensation right now in shares of the company. I believe in this story, I believe in our ability to deliver on this story, and I

think it's a great opportunity for investors.

Dr. Allen Alper: That's very impressive and it sounds like very good reasons why our investors should consider investing in your company. Sounds

like you are at the forefront of metal materials for that technology. Anything else that you'd like to mention?

General Heinz: I think it's worth mentioning again the relationship with NioCorp and where I see the scandium development going. We are looking at that

on two fronts. First is what are the markets and products that would take advantage of a scandium doped or a scandium containing metal? The second is what

are the engineered processes that we truly need to be able to understand in order to be able to produce those parts in the near future? Today, the

marketplace in terms of scandium is scarce and it's scarce because the global availability of scandium is scarce. Its sourcing is unreliable. But we know

that by adding scandium to, for instance, aluminum, it can significantly help aircraft manufacturers reduce weight and improve performance

characteristics. For example, about a million dollars’ worth of scandium doped aluminum can provide $10-15 million in net present value savings in fuel

costs over the life of the aircraft.

Those are pretty dramatic numbers and they are dramatic not only from the sense of what they can accomplish for the individual airline industries, but

also from the perspective of reducing harmful air emissions. As a world, we need to start focusing on how do we begin stemming threats from climate

change caused in part by increased greenhouse gas emissions. There was a time when I didn't believe that climate change driven by human activity existed.

But, I'll tell you, after six years of looking at the data, it is clear to me that weather extremes are becoming more extreme. The human contribution to

that can no longer be ignored. The current forecast is that the Earth will grow by four degrees Celsius in terms of average temperature between now and

2040. That kind of temperature rise means that entire species of animals may no longer exist. We, as a world, need to start focusing on how do we reduce

that rise. I believe that we must eventually eliminate fossil fuel use, or greatly reduce their consumption, and seek to eliminate the pollutants that go

in the atmosphere -- nitrous oxides, for example, that are generated by jet engines. All of those things contribute to climate change. Those are the

things that we're focused on. How can we help with special alloys to solve some of our world's greatest problems? Climate change is definitely one of

them.

Dr. Allen Alper: Sounds like you are doing all the right things and it sounds exciting with what alloys you're working on with Niocorp on scandium

alloys. Sounds great!

401 Arvin Road

Franklin IN USA 46131

Toll Free: (800) 423-5612

T: (317) 738-2558

E: info@ibcadvancedalloys.com

http://www.ibcadvancedalloys.com/

Investor Relations:

Jim Sims

Director of Investor and Public Relations

T: (303) 503-6203

E: jim.sims@ibcadvancedalloys.com

|

|