Stria Lithium Inc. (TSX: SRA) Advances Pontax Lithium Deposit Located in Mining Friendly Quebec, Works to Develop New Technologies for Production of Components for the New Generation of Li- ion Batteries.

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 3/24/2016

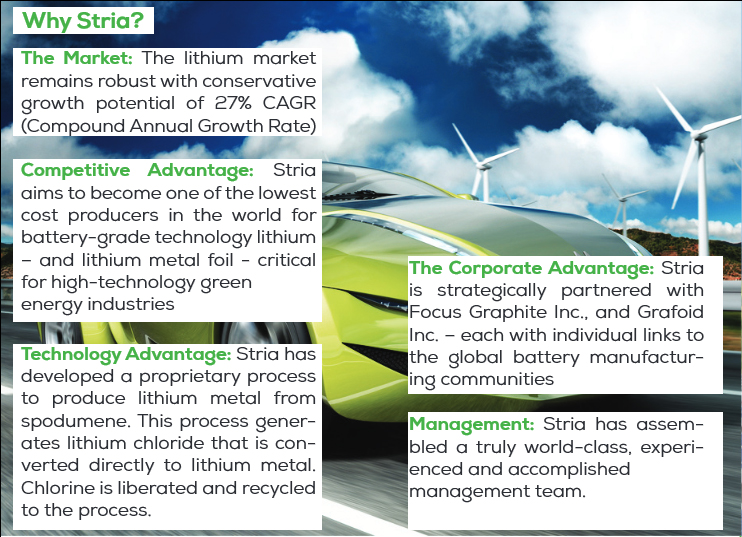

Stria Lithium Inc. (TSX: SRA), is currently focused on advancing their Pontax lithium deposit located in Quebec as well as partnering with sister companies to define new processes for lithium production. Stria is giving value, in the short term, to their shareholders by developing a lithium metals production group in parallel to developing their lithium deposit.

Iain Todd, President and COO of Stria Lithium (TSX: SRA), spoke with Dr. Alper at the recently held PDAC conference to update readers on the focus of his company and their recent developments.

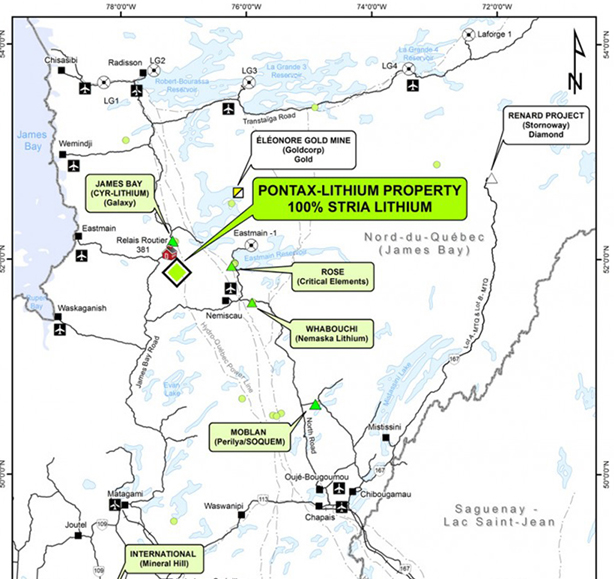

Todd said, “Stria Lithium was created as the entity to push forward the Pontax project after the property was acquired by Stria Capital (now Stria Lithium) from Khalkos Exploration in 2013.The property is located in northern Quebec and is considered an early stage project. We completed a 43-101 early stage report in 2013. Recommendations from that were to go ahead with metallurgical test work prior to further exploration. Metallurgical testing work was completed at the end of 2015, concluding with a successful ore beneficiation pilot plant. The next step is to complete our drilling program. We intend for a two stage process scheduled for initiation by the end of this year. Stage 1 will be to make sure we understand the breadth of the deposit with an extended surface survey and confirmatory drill program. Then the following year, in stage 2, we will execute a program to get a reportable reserves estimate.”

Todd is optimistic about the quality of the deposit and what the company will be able to do with it over the long term. He said, “It is a classic pegmatite dyke swarm and is similar geologically to other Quebec projects that are being developed at the moment as part of that “lithium spine” in northern Quebec which includes Critical Elements, Nemaska, Galaxy, and Perilya. So to date, we don’t see it reacting metallurgically differently from those projects. The target mineral is spodumene. The ore appears to react well to all of the classic processes required to make a concentrate. We are unaware of any processing issues to date and the recommendation has been to continue to move the project forward.”

Todd’s background dovetails with the project and goals for the company. He said, “My background is as a metallurgical engineer and I’ve worked for many years in the development of flow sheets for mining and recycling industries from around the world “.

“For the last ten years, I have been working for SGS Minerals, Lakefield, as the manager of the hydrometallurgical research group. As you can see, I have a very broad experience in metallurgical process and technology development backed by a strong sense of project management. Particularly in the last five or six years, I have been working on a number of lithium projects, which has obviously become a favorite of mine. I’ve worked on brine, hard rock and clays and have a pretty good experience list in developing these kinds of projects.”

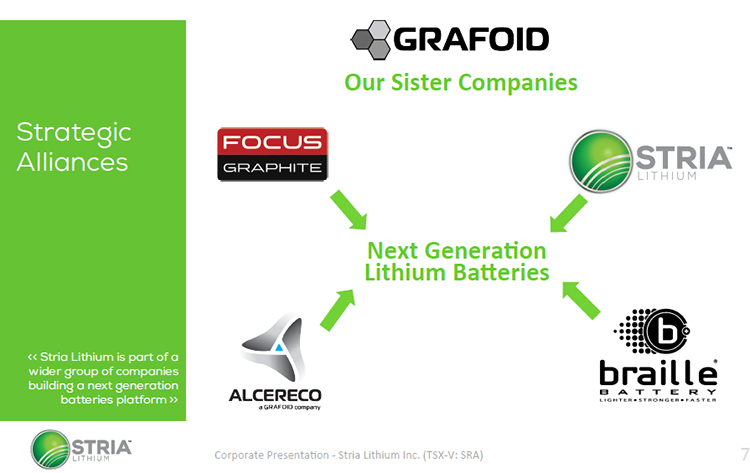

Taking the company forward, Todd and his team have a defined plan. He said, “We have a two pronged approach. Certainly, we would like to continue development of the Pontax property, but as you are aware, that takes a lot of time and money to go to full production with a mine, concentrator, etcetera. We think we can give value to our shareholders by looking at the product end of the flowsheet at this early stage by developing a lithium metals production group in parallel. We are uniquely positioned to take advantage of our sister companies who have knowledge of the technology that can make lithium metals and products including, lithium foil, an important component of the new generation of lithium ion batteries. The Stria Lithium team has a great deal of experience that Todd is leaning on to get the project and their new processes up and running. He said, “we calculated the other day that including our sister companies we have something like 400 man years of technology development experience in similar technologies to lithium metal production, including lithium mine development.”

“We are part of a shared technology hub working under the Grafoid banner at their 200,000sq ft research center in Kingston, Ont. We have focused ourselves on doing all of the development and testing work there at that site. This year we will be providing the required engineering data out of our test work to start design on our lithium metal production facility.”

Said Todd, “there are several companies working out of Kingston as part of the group that Stria belongs to. We have the Stria team that has a proprietary process for converting spodumene to lithium chloride the preferred feedstock for lithium metal production. As well, we have Focus Graphite, developing the advanced stage graphite project at Lac Knife, Quebec. They have also developed a low cost proprietary process for producing very high grade graphite flake for processing for Li Ion batteries. We have Grafoid themselves, who are a graphene research, development and investment company presently managing an $8m grant from the Canadian government to construct the world’s first graphene mass production facility. We also have Alcereco, a specialist group in aluminum and alloy product development, who until 2013 were the Canadian research arm of the aluminum company Novelis.

Said Todd, “There are up to forty people working for these particular groups; so it is a very vibrant and a very experienced technology team that we can draw on. It is not just lithium, but all the future materials required for the next generation of lithium ion batteries.”

Todd believes that investors should take a close look at what Stria Lithium has to offer. He said, “The expected influence on the lithium market of increased electric car production is beginning to be understood. In addition and possibly of greater importance to the market may be the effect of a new generation of domestic energy storage technologies which could be centered on the lithium ion battery. What we know is that the next generation of lithium ion batteries is going to require high purity lithium metal and graphite components, which is why our technology group is so busy at the moment developing new processes to create these products.”

http://strialithium.com/

130 Albert St. Ottawa ON. CA

info@strialithium.com

|

|