Larry Reaugh, the President and CEO of American Manganese (TSX: AMY) recently visited the World Resource Investment Conference in Vancouver to share information about the Artillery Peak manganese property with the investment world.

American Manganese is developing their 43-101 manganese property in Arizona to respond to the needs for electrolytic manganese metal (EMM) and other products (EMD and CMD) that can be used in the steel and rechargeable battery market. Their revolutionary process for breaking down the manganese has resulted in a lower cost process that produces a purer product. The benefits of this process and the development of the property are that it will provide a new source of manganese to the steel industry, where there is no substitute, as well as offer a strategic resource located right on American soil. The manganese process that the company is using is so revolutionary that they have been granted a patent to protect their technology.

Reaugh is pleased with the progress that the company has made in developing the project and the associated processing technology. He said, “As you know, we have the largest manganese resource in the Southwestern US. We have a US patent that has been issued and protects our technology to make a high purity electrolytic manganese metal (EMM) electrolytic manganese dioxide (EMD) and chemical manganese dioxide (CMD) for the steel and Rechargeable Lithium Ion Manganese Battery Market .”

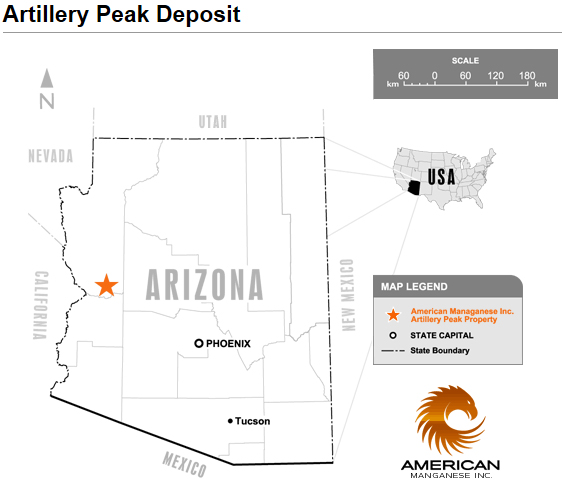

The project is located centrally in the southwest of the United States, with easy access to major cities and transportation. Reaugh said, “Our project is about a three hour drive from Las Vegas. It is called Artillery Creek.” Originally, the project was mined to add resources to the government’s supply, though that ended several years ago. Reaugh said, “It was mined in the past for the strategic stockpile. There are no operating manganese mines in the United States even though it is considered the 2nd most strategic metal in the US”

As with every company that is currently trading on the market, it has been a difficult season for American Manganese, though Reaugh is hopeful that the worst is just about over. He said, “The markets always recover.” Reaugh believes that the cyclical nature of the markets has drawn the challenges nearly to an end. He said, “I know everyone is talking about the gloom and doom in the market. That tells me that it is about ready to capitulate and hit bottom.” Like many other CEO’s, Reaugh is hopeful that once the market hits bottom, it will become easier to conduct business on a project that is ready to move forward. For American Manganese, that would mean an opportunity to raise some additional funds to forward their project. Reaugh said, “As soon as we can raise money, we’ll get started on making the dioxide for the battery concentrate.”

The specific process for creating the battery concentrate offers economical possibilities for the company and a high purity product for end users. Reaugh said, “The reality is that the product only requires 60% of the metal per pound, the rest is oxygen.” With a higher purity product, a new way to access the manganese out of the rock, and the ability to combine it with oxygen, the company has potentially reduced the processing costs significantly. Said Reaugh, “We are in the lowest percentile for operating costs for electrolytic manganese in the world.”

Reaugh believes that the need for batteries in all types of products, including technology and automobiles will continue to push the manganese sector for the long term. He said, “The fastest growing sector of the market, as you know, is the rechargeable batteries.” Even with this scenario, there are very few producers in the United States. This is causing a significant shortfall in a metal that is critical for steel and battery production. Reaugh said, “There are only three producers of EMD in the US.” The remaining metal that is brought in to the United States has been imported and has issues with purity. Reaugh said, “Production in the US is from imported finds from Gabon.” In fact, companies importing finds do not have the benefit of American Manganese’s newly patented process, leaving them open for purity and processing cost issues. Said Reaugh, “During the process they have to crush, grind and roast the manganese ore before leaching.” This is where the weak link in the old process is, as it can add in minute metal particles that are not favorable for end use. Reaugh said, “This can introduce metal particles that can cause shorts and thermal runaway resulting in fires and explosions.” The process that American Manganese uses allows the purity of the metal to be maintained, which eliminates the possibility of other metals being introduced into the concentrate. Reaugh said, “Our process is the same one used for coal. We lightly impact the rock down to ¼ inch and use a mild sulfuric acid to leach it.” The result is that the manganese is extracted without any risk of rogue metals. Said Reaugh, “We have a high purity product free of rogue metal particles introduced in the processing of the concentrate. We are talking about high purity because the omission of metals is in the parts per billion.”

Future plans for the company include reducing the land package to a more manageable size.

Continuing development of the Artillery Creek project and evaluating other property options. In addition, the company will be continuing to look for ways to supply the manganese markets and will be pursing their patented process around the globe. Reaugh said, “We are always looking at other projects. We think we have a robust project on our hands. I leave you with this idea. The U.S. is getting rid of our strategic stockpiles. We could be their strategic source of metals. We could get it for the Army or the Defense Department and could meet their needs immediately if we can get this into production. We have applied for patents in other countries as well.”

http://www.americanmanganeseinc.com/

Head Office:

2A 15782 Marine Drive

White Rock, BC CANADA

V4B 1E6

Larry W. Reaugh

lreaugh@amymn.com