Enertopia Corporation (OTCQB: ENRT, CSE: TOP): Emerging Lithium Opportunity, Interview with Robert McAllister, President and CEO

|

By Allen Alper, Jr.

on 3/29/2018

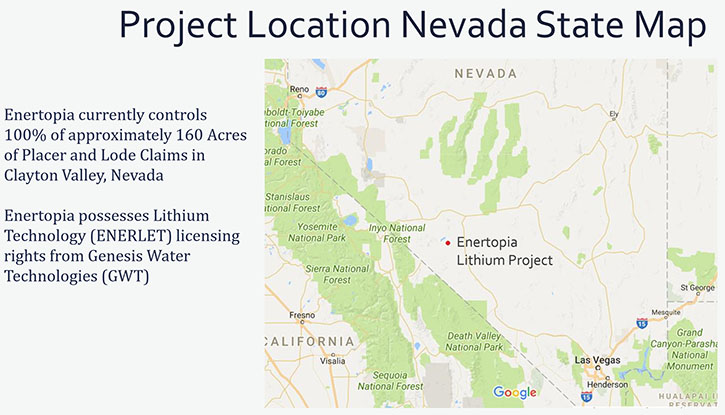

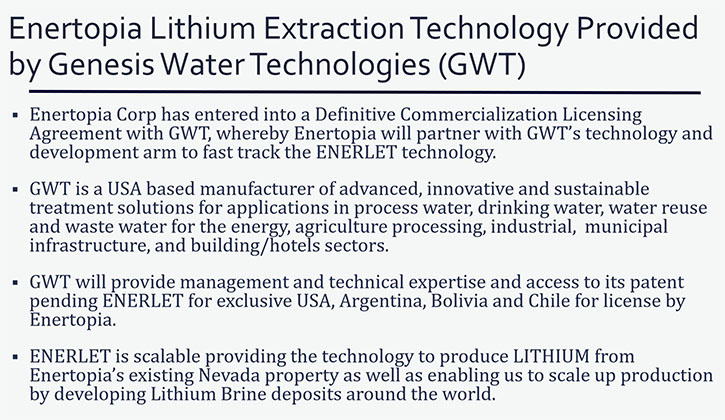

Enertopia Corporation (OTCQB: ENRT, CSE: TOP) is an exploration and development company, which has engaged Genesis Water Technologies (GWT) to adapt their technology to be able to produce battery-grade lithium carbonate from brines, or the creation of a synthetic brine from the company’s lithium project in Clayton Valley, Nevada, U.S., located near Albemarle's Silver Peak lithium brine mine. Enertopia has the technology licensing rights for the USA, Argentina, Bolivia, and Chile. We learned from Robert McAllister, President and CEO of Enertopia, that their process takes a couple hours to create the solution to potentially come up with battery grade Lithium carbonate, compared to 12 to 18 months currently in the industry. The near-term plans include completing the bench test confirming battery grade, then working on a 43-101 resource update.

Robert McAllister, President and CEO of Enertopia at PDAC 2018

Western Claim Boundary Looking North

Allen Alper Jr.: This is Allen Alper with Metals News. I'm interviewing Robert McAllister, CEO of Enertopia Corp. Could you tell our readers/investors a bit about yourself and give them an overview of your company, your focus and your properties?

Mr. Robert McAllister: My background, in the mining industry, goes back to 1987 as a sole investor in the space. Then I moved on to doing a newsletter 1996 to 2003 mostly covering Oil and Gas and Mining Stocks. Then, I went into the investor relations side with Red Hawk Resources from 2003 through 2006. Then I started running my own public company and have been doing that since 2008. I have been with Enertopia since 2008. Here we are today in the Lithium space for the last two years. We're working with a technology partner on extracting battery grade Lithium from brines. We're showcased our story at PDAC 2018.

Allen Alper Jr.: Would you like to tell us a bit about your property, and what stage you're at? It looks like you're doing something interesting.

Mr. Robert McAllister: We are doing several things. We're on the uplifted fault block in Clayton Valley, Nevada. We're about a mile and a half from the Albemarle Brine Operation, which is the only Lithium mine producing in the United States. When you look at it on our poster, you can see the settling ponds in the background, with the blue color. Then what you see are the mineralized lithium outcrops, we're looking at the west edge of our property and we're looking north. Above that's Enertopia property. What you're seeing with the Genesis water technologies, is an electro coagulation unit. It's a photo showing how it works through the slurry. That's just one part of the process to come up with what we hope to be battery grade Lithium carbonate, which is what is ongoing right now with our bench test. We expect results by the end of May. It's the second series of testing.

Last year we did our first bench test with Genesis, and we came up with 96.9%. We need 99.5% currently for battery grade material. That was a $10,000 test. This test is $200,000 US, so it's a significant increase in scale and scope. We've brought in some technical fire power, both with Genesis and then on our own technical team, and that's where we are today. Then we had a display for PDAC, to show what happens with the surface source rock. It's actually very hard rock in place, but it becomes very brittle. You can break it easily. We showed, how the rock dissolves in about 15 minutes in bottled water, drinking water, just in the water.

In the last three months, we've had bench testing done with a third party lab in Canada. We ran different scenarios at different pH s. So sulfuric acid with a pH of 2 dissolves everything. You get a higher recovery to start with, but then you have to fight all the impurities, because you need to take everything out to have battery grade. You're not allowed any Magnesium, no Iron. Three parts per million for Aluminum, very small, minute quantities. There can be no interference when it's used for battery grade in batteries. What we've found is, when we raised the pH to 11, almost all those impurities stay in the rock and do not precipitate into the liquid. We come up with a very pure solution of Lithium, with hardly any Magnesium. If you use sulfuric acid magnesium would be 2% in solution. By using the high pH of 11 we're getting less than one part per million, so then we have this clean solution that will go through the Genesis process.

Allen Alper Jr.: Are you still getting good recoveries with that higher pH?

Mr. Robert McAllister: We get a lower recovery of the Lithium, but we remove almost all the bad materials, so the Magnesium, the Calcium, Iron, Cobalt, whatever it might be we are dealing with impurities in low ppm’s and not in percentages before this material is processed.

Allen Alper Jr.: That makes sense.

Mr. Robert McAllister: That's right. We're starting with the purest form brine solution in the industry today. We think that gives us a step up.

Allen Alper Jr.: That's great. When are you concluding your bench testing?

Mr. Robert McAllister: The bench test, actually the build completes this week. We have two months of testing through solutions that we're making up. We expect results about the end of May.

Allen Alper Jr.: Great!

Mr. Robert McAllister: Pretty quick.

Allen Alper Jr.: Yes. What would your next step be after that?

Mr. Robert McAllister: After that is battery grade. Then we would do some shallow drilling on our property, which has been drilled beside us, so we know how the resource lies, but we need to know exactly from where we're going to take the bulk tonnage material and build a pilot plant, which should be close to $3 million US.

Allen Alper Jr.: Okay. Can you tell us a little bit about your management team?

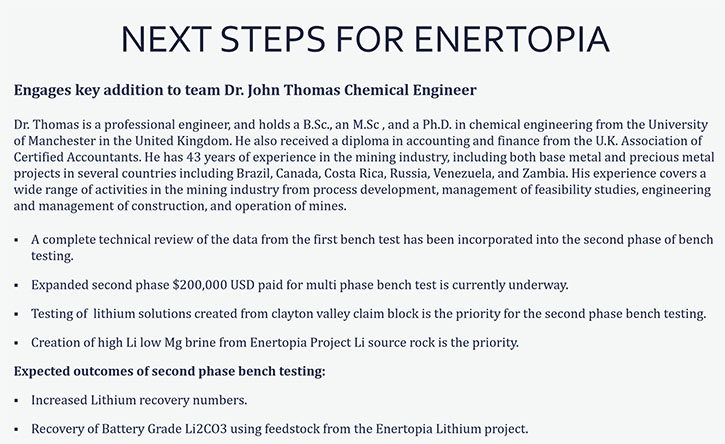

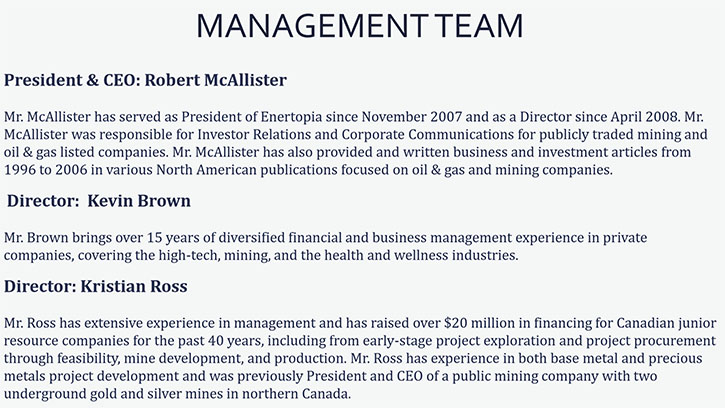

Mr. Robert McAllister: Management team is myself. Kristian Ross, who used to be the President of Redhawk Resources and has 40 years of mining and mineral experience in the United States and Canada. Dr. John Thomas, he's our big technical person. He has over 40 years in the mining industry, open pit mines and underground mines. He's been instrumental in helping move us along with the PH testing and extracting the most amount of Lithium with the least amount of deleterious elements.

Allen Alper Jr.: Great. Tell us a little bit about your share structure.

Mr. Robert McAllister: We have 110 million shares, issued and outstanding, 36 million warrants, and 7 million options. If the warrants were exercised, about $2.8 million dollars US would be brought into the treasury.

Allen Alper Jr.: What type of investment do you have in the company? Do you have skin in the game?

Mr. Robert McAllister: I have skin in the game. I have 5%. Five million shares that I've paid for in private placements over the years including our most recent PP.

Allen Alper Jr.: What do you think are the main reasons an investor would want to invest in Enertopia?

Mr. Robert McAllister: First would be our technology. We have a process that takes a couple hours to create the solution to come up with potential battery grade Lithium carbonate. Right now in the industry it's 12 to 18 months. That time savings is a game changer. The second step is the project itself. We can create a clean Lithium brine that could be used or sold to somebody else potentially, without going through our process. But we want to put it through our process to get the maximum amount of return for investors.

Allen Alper Jr.: What do you see as your biggest challenges right now?

Mr. Robert McAllister: Near term would be showing that the process works, that the bench test works, so we can go to the next step. That's our biggest challenge. On the project side, people have drilled beside us on both sides, so we know it’s a blanket horizon, it's fairly uniform throughout, so we have very little geological risk. We know that the Lithium space is going from 1 million electric vehicles this year to over 20 million vehicles by 2030, with the Chinese mandate alone of no internal combustion engine vehicles to be manufactured in their country by 2030.

Allen Alper Jr.: Do you have an idea of the size of your resource?

Mr. Robert McAllister: Well, we have no measured and indicated resource yet. One company, beside us, to the north and east, has a shallow resource of just under 100,000 tons of Lithium carbonate. That's over 100 acres down to a 50 foot depth. There's another company to our west that’s coming out in the next month or so with a much larger resource, because they have drilled down from surface to 300 feet. Everybody's chatting about that resource, it is going to be large.

Allen Alper Jr.: What do you plan next?

Mr. Robert McAllister: After the bench test confirms battery grade, we will work on a 43-101 update. Because then we'd have some drilling and our bench test numbers.

Allen Alper Jr.: Is there anything you’d like to add?

Mr. Robert McAllister: Just to say thank you for coming by our booth and listening to our story today.

Allen Alper Jr.: You are welcome. It has been very interesting.

http://www.enertopia.com/

Robert McAllister

President/CEO

250-765-6412

|

|