Stria Lithium Accomplishes Goal of Isolating Lithium Chloride Using Environmentally Safe Process

|

By Allen Alper Jr.

on 6/23/2014

Julien Davy, the President and COO of Stria Lithium (TSX: SRA), took some time to speak with Metals News about their new proprietary process that allows them to isolate lithium chloride. Julien Davy, the President and COO of Stria Lithium (TSX: SRA), took some time to speak with Metals News about their new proprietary process that allows them to isolate lithium chloride.

Said Davy, “I’m a geologist. I have worked for different companies like Hecla Mining and Anglo American. I then chose to get my MBA to understand the financial aspect of evaluating projects. That was the kind of job I did after I graduated working for Osisko Mining, working on their evaluation and acquisitions team. I met Gary Economo and had a meeting regarding his new company, Stria Lithium. It has been listed since December, 2013.” After that meeting, Davy decided to join the Stria group. Said Davy, “I accepted the position of VP Exploration.” Shortly thereafter, Davy was promoted to a new position. He said, “Pretty quickly, I was appointed President and COO.”

Davy explained that industry newcomer Stria is currently pursuing two different business tracks he believes critical to the company’s future success. He said, “Stria has two different aspects, exploration, of course, but we have what we believe to be a larger play on the technology side. Our proprietary process holds the potential for us to produce lithium metal at a lower cost in a green, environmentally sustainable way. The environmental aspect is extremely important to us.” The process that the team at Stria has developed will allow for less chemical usage and more recovery and recycling of those chemicals used. Said Davy, “We will need fewer chemicals; we will only be using them in a closed loop, and we will recover all of the chemicals. It will be an environmentally sensitive project.”

Close-up view of Pontax's spodumene-bearing pegmatite. The light grey spodumene is idiomorphic and lath-shaped. The intergranular grey mineral is quartz.

On May 20, 2014, the company published information confirming its ability to recover an intermediate lithium chloride concentrate. Said Davy, “Our proof of principal paper, showed that we are able to recover the lithium chloride product. That was the most difficult part of the project for us. We achieved it. This is the part that will be used to process the lithium chloride to other products. As a company developing technologies targeted for use by the global battery manufacturing sector achieving our Phase 1 proof of principle propels us into Phase 2 pilot plant preparations. We know that the electronics market will grow. And demand for all materials required for the electric vehicle and electronics sector will grow with it. It is more a question of when it will happen than if it will happen. Stria is positioning itself by building a competitive advantage for itself in this growing market.”

One of the major users of lithium is the car manufacturing business, particularly those involved in electric cars. Said Davy, “When you buy an electric or hybrid electric car, the majority of the car’s costs are tied to the battery. Manufacturers understand that they need to reduce the cost of the battery and they want to have longer life batteries that can significantly extend driving distances.” In order to achieve that goal, the industry needs lithium with a higher purity level, which is something that Stria has been working on. Said Davy, “That is a question of the purity of the lithium. That is the beauty of the process we are developing. Our aim is to achieve a 99.999% product on an economically scalable basis – a process that aims to remove virtually all impurities in the lithium.”

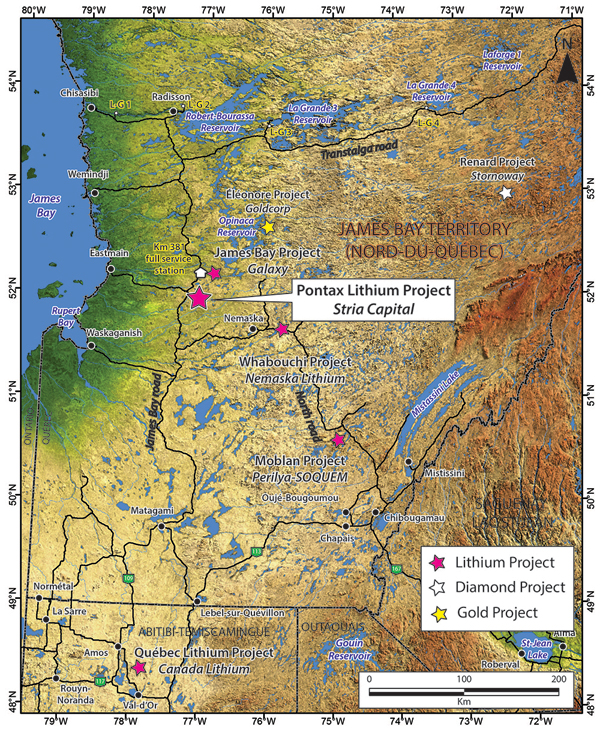

In addition to working on their process for lithium recovery, Stria also has exploration properties. Said Davy, “We have some spodumene properties in the James Bay area of Northern Quebec and a brine property in Arizona. These are two exploration properties that we are using to source the ore that we are using to develop our technology. We are actively seeking to acquire more exploration properties.”

While the company has properties, they are focused on their lithium process at the moment. Said Davy, “We are more focused on our proprietary process right now. Going forward, what we are looking for is to achieve different types of agreements with lithium manufacturers. The pilot plant we are designing now will help us to define the economics of the process.”

Stria’s marketing efforts are tied in with those of its strategic partners. Said Davy, “We are in a relationship with Focus Graphite, which has an interest in global battery manufacturing and has the well-advanced Lac Knife flake graphite deposit. The other partnership is with Grafoid Inc., a leading Canadian graphene development company with global industrial reach with R&D and production facilities in Kingston, Ontario and later this year, the United States. Because of this partnership, we have access to the research facility where we have other metallurgists working on the project. They have the background, and experience in the lithium sector.”

Why should investors take a look at Stria Lithium? Davy said, “We have fully diluted around 17 million shares, we are trading between $0.16 and $0.20 cents right now with a $2.5 million dollar market cap. We are currently in the optimization phase. The data we generate from this phase will be used for the design of the pilot plant and ultimately, confirm our goals of achieving production of marketable lithium products. We now know that it is possible to recover the lithium chloride concentrate. As an investment, Stria’s technology focus has led to an innovative, environmentally sustainable process with the potential, if successful, to set market prices for battery-grade lithium metal. Our science and management team is world class, and our marketing strengths are tied strategically to our partnership network. I believe the approach we’ve taken as a newcomer to the lithium sector differentiates us from our competitors and we’ll continue to build our business upon our technology strengths.”

http://strialithium.com/

912-130

Albert Street

Ottawa, Ontario

K1P 5G4

Phone: 613-702-0789613-702-0789

Fax: 613-241-8632

|

|