Altech Chemicals (ASX: ATC) Set to Produce High Purity Alumina at Low Cost in Near Future

|

By Allen Alper Jr.

on 12/31/2015

Iggy Tan, the managing director of Altech Chemicals (ASX: ATC) took some time to explain to the readers of Metals News the progress that the company has made on developing its high purity alumina project, which proposes the operation of a processing facility in Malaysia using feedstock sourced from its Meckering kaolin deposit in Western Australia.

When talking about the company, Tan said, “Altech Chemicals is aiming to become one of the world’s leading producers of high purity alumina. Among its many varied uses, high purity alumina is used in the manufacture of artificial sapphire.”

Demand for artificial sapphires today is rapidly increasing mainly due to its superior properties including extreme hardness (nearly as hard as diamond), heat and chemical resistance. Tan said, “Sapphires, like any naturally occurring gemstone, are formed by intense heat, pressure and movement originating within earth’s crust. Sapphire is a crystal form of aluminum oxide, or commonly known as alumina.”

Based on its superior qualities such as extreme hardness, artificial sapphire is manufactured using high purity alumina under intense pressure and heat; the formation occurs in high-tech furnaces where large single sapphire crystals are grown from high-quality aluminum oxide (HPA). From these single sapphire crystals, sapphire wafers and sapphire glass are extracted using diamond-cutting technology.

Today, artificial sapphire is playing a large and growing part in our everyday, modern lives.

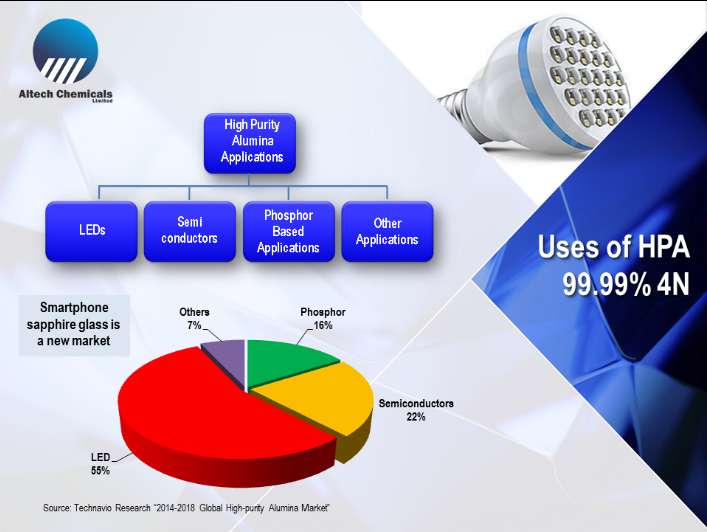

Sapphire wafers are used in the manufacture of cost-effective, energy-efficient LEDs. Dubbed as the lighting of the future, LEDs offer huge energy savings and are rapidly replacing traditional light globes around the world today. Semiconductor components found in our electronic devices, phosphor plasma televisions, and scratchproof watches are some of the many applications that belong to the sapphire family.

Smartphone manufacturers are already making the exciting transition to the un-scratchable sapphire display screens.

“About 55% of the world’s high purity alumina is used to make LEDs; about 22% is used for semiconductor components, and 16% for phosphor display screens.

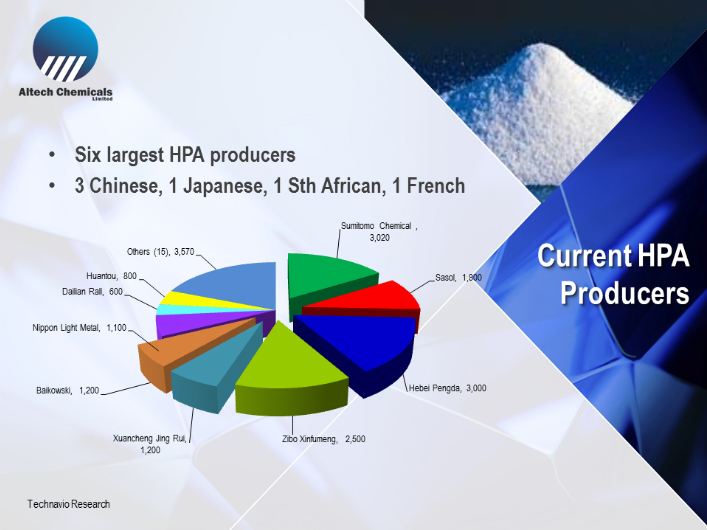

Some of the current major HPA producers range from French, South African, Chinese and Japanese companies. In order to meet the specification of 99.99% (4N) Al2O3 purity for the sapphires, these producers need a very high grade of feedstock to produce HPA at this high quality. Some use expensive aluminum metal as their feedstock and dissolve it using alcohol. The process is relatively costly due to the highly-processed and expensive feedstock of $4000 per ton.”

Getting the aluminum is the first hurdle in the production process. Tan said, “Aluminum comes from the smelting process. Smelter grade aluminum is dissolved to make aluminum metal and then HPA producers buy it. If you think about it, it is a lengthy process to get to the upside. Our process is that we take the ore and we process it in one step.”

The company’s Meckering deposit in Western Australia contains kaolin clay that has very low impurities such as iron and sodium. Tan said, “The only reason we can process HPA directly from our feedstock is because of the quality of the ore body we have – it has very low impurities and high alumina content. We extract the HPA using a hydrochloric acid based process. The advantage of this process versus the caustic soda is that the caustic soda gets caught in the crystal lattice. So, when you try to make a very high purity product, it becomes a major problem to meet the purity required by the electronics industry.”

The hydrochloric acid process has been used for decades. Tan said, “The reason we use the hydrochloric acid process is that it is highly capable of making alumina but specifically very high purity alumina. The technology has been around since the 1980’s; Alcoa first developed the process based on a shortage of aluminium in the United States. But demand for a very pure alumina product was negligible compared to today so the HCl process was never further developed.”

Now, with the demand for a high-quality alumina product much higher, the team at Altech Chemicals is moving forward to offer high purity alumina for the artificial sapphire, LED and electronics industries. Tan said, “We have finished a bankable feasibility study and based on the results we will have competitive production costs. We are well positioned to cater to customers in the Asia-Pacific region as our operation is based both in Australia and Malaysia. We have just announced a funding package with the support of a German bank. This is very exciting.”

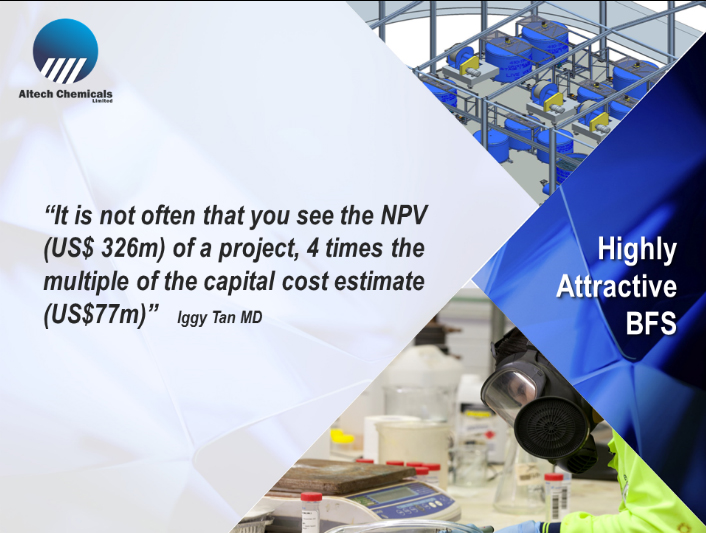

The numbers are in on the project and Tan is confident that they are positive. He said, “The capex will be about US$77 million. The value of the project will be about US$326 million. Our operating cost will be about $8000 a ton. We expect that it will end up to be between $7000 and $8000 a ton because we are working in a low-cost country like Malaysia. Our next phase is to finish the funding of the project and work on the detailed design. We are working with a German company on the design and we will be negotiating offtake agreements and finalising approvals on the project. It will take about nine months to get that underway and we will look at breaking ground in the next three or four quarters.”

Why should investors take a close look at Altech Chemicals? Tan said, “This is a high margin, high profit project that will support LEDs and other emerging high-tech applications. We expect to have a payback in just over two years. It is a highly attractive project.”

For more information visit http://www.altechchemicals.com

Altech Chemicals Limited

Suite 8, 295 Rokeby Road,

Subiaco,

WA, 6008

+61 (08) 6168 1555

+61 (08) 6168 1551

info@altechchemicals.com

|

|