Dr. Mark Cooksey, CEO, Alcore Limited, Discusses Becoming the First Low-Cost, Environmentally Friendly Producer of Aluminum Fluoride in Australia, Essential for Aluminum Smelting

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 8/17/2021

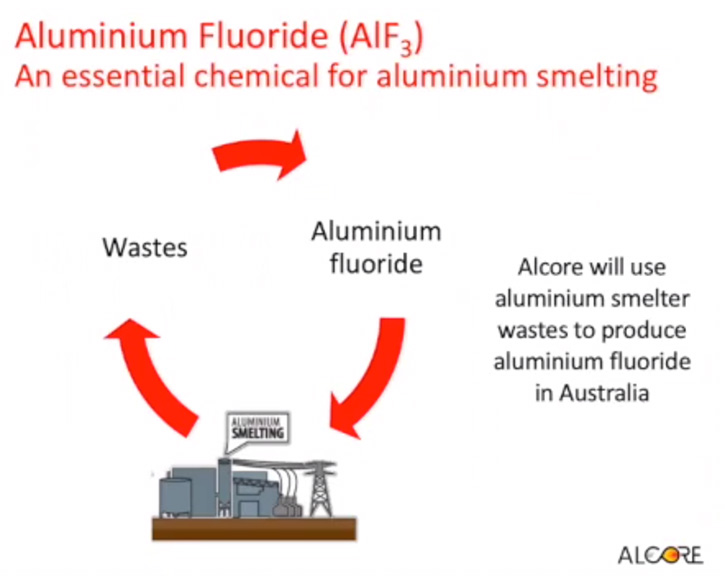

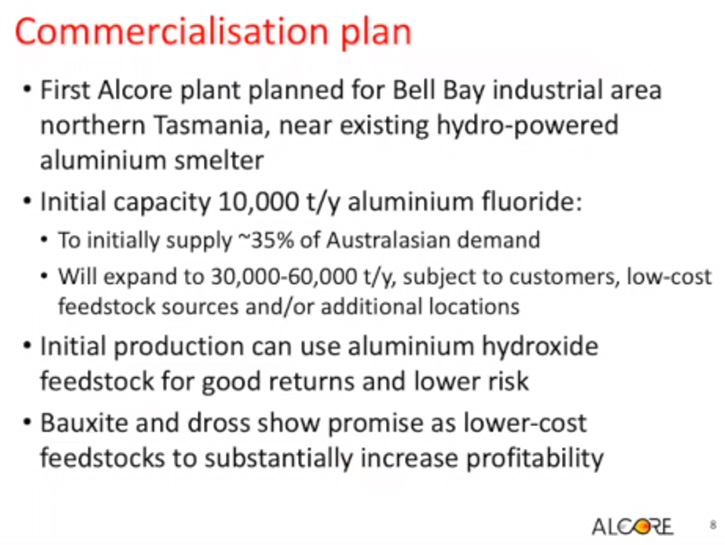

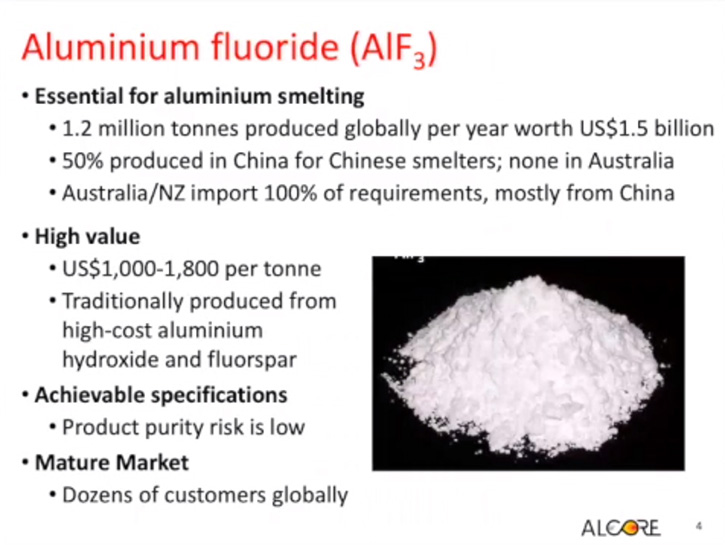

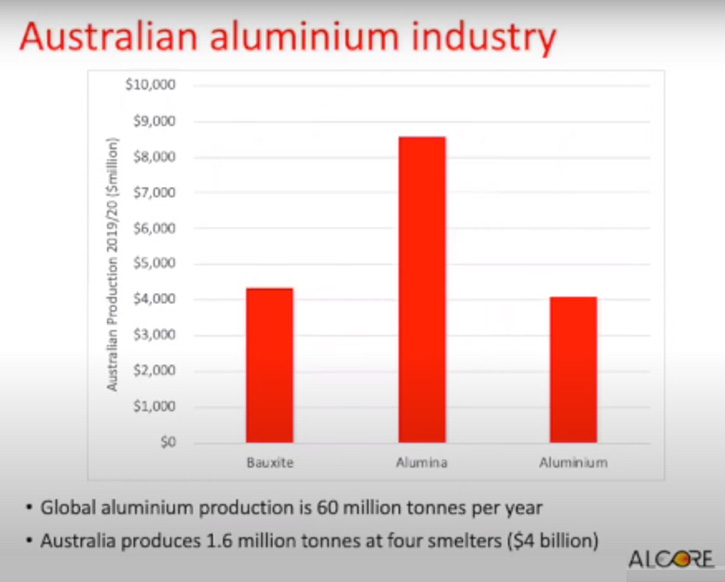

We learned from Dr. Mark Cooksey, of Alcore Limited, that they are aiming to become the first low-cost, environmentally friendly producer of aluminum fluoride in Australia. Aluminum fluoride is a critical mineral, essential for aluminum smelting. Australia/NZ currently imports 100% of its aluminum fluoride requirement, mostly from China. Alcore plans to use aluminum smelter wastes to produce aluminum fluoride. The first Alcore plant, with initial capacity of 10000 t/y, about 35% of Australian/NZ demand, is planned for northern Tasmania, near an existing hydro-powered aluminum smelter. The plant will be able to expand to 30000-60000 t/y. Alcore has already successfully achieved proof of concept, by producing aluminum fluoride, from aluminum smelter wastes, in a laboratory. Next step is to proceed with engineering validation, including pilot plant.

Dr. Allen Alper: This is Dr. Allen Alper, Editor-in-chief of Metals News, talking with Dr. Mark Cooksey from Alcore Limited. Could you update our readers/investors, an overview of Alcore?

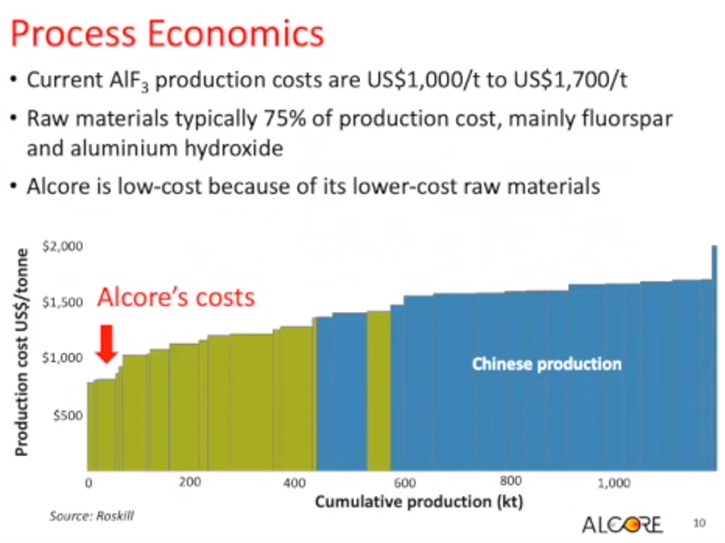

Dr. Mark Cooksey:Alcore is a high technology company, developing a new process to produce aluminum fluoride, an essential chemical for aluminum smelting. Our new process involves the use of lower-cost raw materials, including waste materials, from the aluminum smelting process itself. So we'll be producing aluminum fluoride at lower costs and with more environmental benefits. We'll be building a plant in Australia, which will be the first time Australia has produced aluminum fluoride.

Dr. Allen Alper: Well, that's great! Could you tell us a little bit more about the process and also what quantities will be produced, et cetera?

Dr. Mark Cooksey: The aluminum fluoride global market is over a million tons. Our initial project is to be 10,000 tons, about 1% of the global market. That's also about one third of the Australian market. Over time we look to expand up to say 50,000 tons, where we would supply the entire Australian market and export to Asia Pacific for example. There are two parts to the process to make aluminum fluoride. You need aluminum and fluorine. A key part of our process is getting fluorine more economically. Fluoride is currently obtained from fluorspar, it's quite expensive and has to be mined. We're going to get it from what's called tapped bath, which is a waste material from the aluminum smelting process.

We're using some clever chemistry to extract the fluorine from that bath. On the aluminum side, we can use the current aluminum source, which is aluminum hydroxide. But we're also looking at using, lower cost materials, such as bauxite or dross. Dross is another waste material from the aluminum smelting process that contains a lot of aluminum. We're using clever chemistry to extract the aluminum from bauxite or dross whilst not allowing the impurities in those to contaminate the aluminum fluoride.

Dr. Allen Alper: Well, that sounds excellent! Could you tell our readers/investors the primary uses of the aluminum fluoride?

Dr. Mark Cooksey: Absolutely! 90% of it is used in aluminum smelting now. So that's really the dominant market. It is being looked at, actively, for lithium-ion batteries, like in the separator. It's certainly a significant potential growth market, but at the time, Alcore is mainly focused on the aluminum smelting market.

Dr. Allen Alper: Sounds excellent. Could you tell our readers/investors about yourself, your Team, and your Board?

Dr. Mark Cooksey: Sure. I'm a chemical engineer. I started my career with Rio Tinto in Australia, in aluminum smelting. I then worked for more than a decade at CSIRO, which is Australia's national science agency. I've led the technical and commercial development of a range of minerals and metals processes. I joined Alcore 18 months ago, to lead the process development and commercialization of the aluminum fluoride production technology. We're a small Team still but we are currently expanding. The Board is very experienced, led by Paul Lennon, a former Premier of Tasmania. There is Ian Levy, a geologist with more than 30 years of senior management experience with mining companies, such as WMC. And Rex Adams, another geologist, a former partner and mining analyst at Blue Ocean Equities and Southern Cross Equities.

Dr. Allen Alper: Could you tell our readers/investors, the primary goals for the remainder of 2021 going into 2022?

Dr. Mark Cooksey: The key objective of 2021 is to pilot our process. We've already demonstrated most of the key requirements at laboratory scale, so we now need to pilot it at larger scale, to confirm the process and generate the data that can allow us to build the commercial plant.

Dr. Allen Alper: That sounds excellent. Could you tell our readers\investors a little bit about your capital and share structure?

Dr. Mark Cooksey:Alcore is an unlisted, public company. I It is an 87%-owned subsidiary of Australian Bauxite, which is listed on the Australian stock exchange. The other 13% is made up of seed investors. The total share capital is over four million dollars. We recently raised more funds, allowing us to more than complete the pilot plant stage.

Dr. Allen Alper: That sounds excellent. Could you tell our readers/investors, the primary reasons that they should consider investing in Alcore and Australian Bauxite?

Dr. Mark Cooksey: The aluminum fluoride market is a very certain market in terms of aluminum smelting being a major industry. There is no substitute for aluminum fluoride, and aluminum smelting is growing. So the minimum demand for aluminum fluoride is very well known, plus the upside from, for example, lithium ion batteries. Aluminum fluoride production is pretty consistent around the world. 75% of the cost of production is the raw materials. So Alcore is coming in saying, "Using clever chemistry, we can use different raw materials, which allow us to produce aluminum fluoride at a significantly lower cost." We're going to be a low-cost entrant into a market that's definitely there. And the scale up is not too difficult. It uses a lot of similar process equipment to what's used now. It's just doing some different chemistry.

Julie Young:Alcore is strategically important to Australia, with regards to aluminum smelters. They don't have an Australian source of aluminum fluoride. This is very different from a lot of other countries, which have local aluminum fluoride supply for their aluminum smelters.

Dr. Allen Alper: Well, that's an outstanding reason to develop an aluminum fluoride process and move it to production. Is there anything else that either of you would like to add?

Dr. Mark Cooksey: I have 20 years’ experience, developing new processes, for the minerals and metals industry. It's difficult and it can take a long time to develop ideas and scale them up to commercialization. The reason I joined Alcore was because I think this opportunity has a very high probability of success. It's a well-known market, the product requirements aren't particularly high, and we have a very well-developed idea and process for substantially reducing the production costs. So, all those reasons stack up very well.

Dr. Allen Alper: Well, that sounds excellent! We’ll publish your press releases as they come out so our readers/investors can follow your progress.

Julie Young

Marketing & Investor Relations Manager

jyoung@australianbauxite.com.au

|

|