Canada Silver Cobalt Works Inc. (TSXV: CCW) (OTC: CCWOF): Resource is Over 7 million Oz of silver at 250 Oz a ton, the Highest Grade Mine, Exploration Upside for Silver, Cobalt, Nickel, Gold and Copper; Frank Basa, Chairman and CEO Interviewed

|

By Dr. Allen Alper, PhD Economic Geology and Petrology, Columbia University, NYC, USA

on 6/22/2021

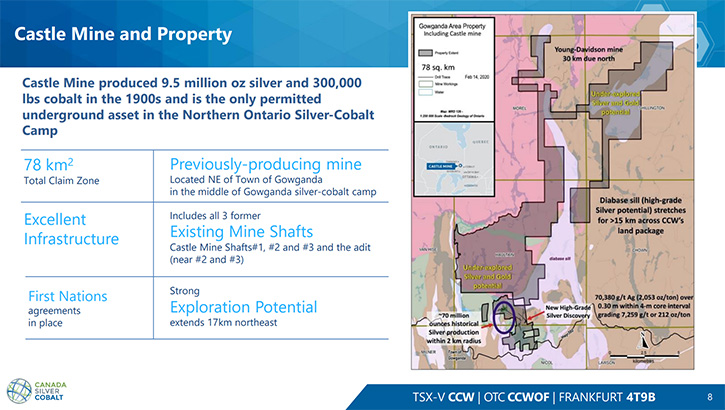

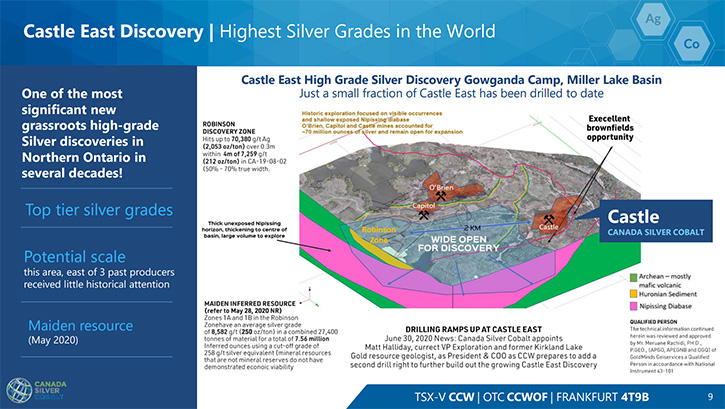

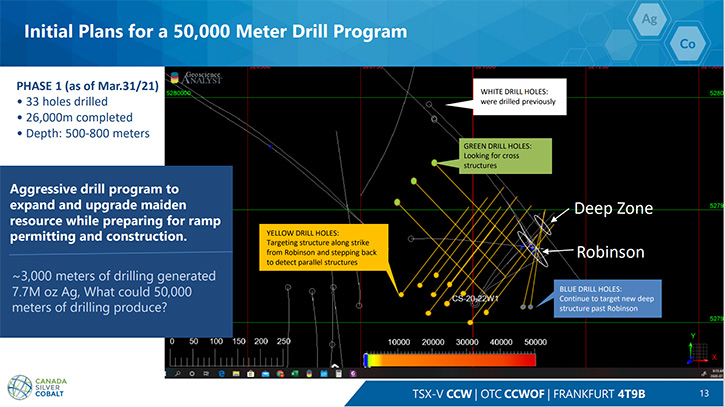

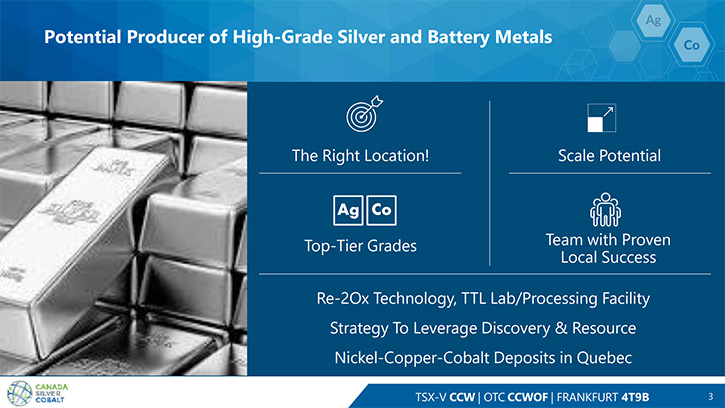

We spoke with Frank Basa, who is Chairman and CEO of Canada Silver Cobalt Works Inc. (TSXV: CCW) (OTC: CCWOF). Their flagship Castle Mine and 78 sq. km Castle Property features strong exploration upside for silver, cobalt, nickel, gold and copper in the prolific, past producing, Gowganda high-grade Silver District of Northern Ontario. We learned from Mr. Basa, that their present resource is a little over 7 million ounces of silver at 250 ounces a ton, which is the highest grade mine anywhere in the world, by an order of magnitude. The Company is currently in the middle of a 50,000-meter drilling program, and their target is 30 million ounces of silver resource. In addition to silver, the property contains a lot of cobalt, copper, nickel and gold. We learned from Mr. Basa that they are capable of producing technical grade cobalt sulphate, as well as nickel-manganese-cobalt (NMC) formulations, using their proprietary, environmentally friendly, hydrometallurgical process, known as Re-2Ox.

Dr. Allen Alper:

This is Dr. Allen Alper, Editor-in-Chief of Metals News interviewing Frank Basa, who is Chairman and CEO of Canada Silver Cobalt Works, Inc. Frank, I wonder if you could give our readers/investors an overview of your Company and what differentiates your Company from others? I know you're in a fantastic location for cobalt and for silver and you have a great history. Could you give our readers/investors an overview and what makes your Company unique?

Frank Basa:

What we have is a former producer in the Cobalt Camp. The Cobalt Camp itself is quite large, it's about 180 Kilometers across and there are about 108 mines that operated, through the years, in the Camp. Some of the larger mining companies have roots here, they started here. It's an area rich in very high-grade silver and a lot of native silver. It also has the benefit of having a lot of cobalt. The town is called Cobalt, but the majority of what's been mined through the years has been silver. They actually threw a lot of the cobalt away.

We picked up a very high-grade mine that was operated by Agnico Mines in its days in the Camp. I used to work for Agnico there in the 1980s. The mine, which closed in 1989 due to a low silver price, became available about 11 years ago and we picked it up for $25,000 when silver wasn't such an exciting topic, nor cobalt. We've taken that property and put it into this Company, which was a distressed shell, and that's how Canada Silver Cobalt came about.

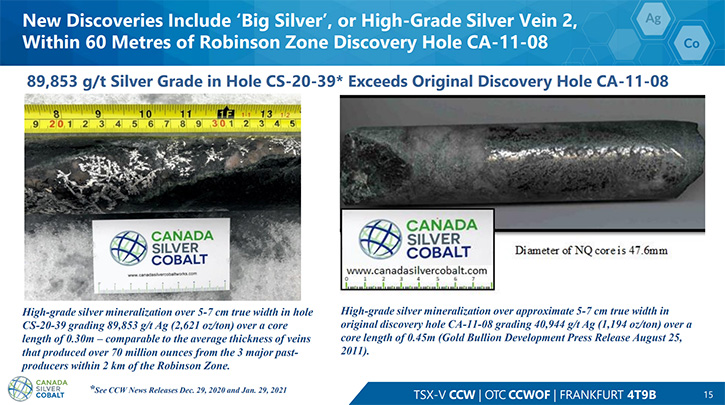

We had a major discovery at the Castle property, while drilling in 2011, but we didn’t proceed with further exploration at that time. Then more recently we lowered a downhole camera into the original drill hole, we figured out the orientation of the silver vein and we started a drilling program of 50,000 meters, and we have a little over 30,000 meters done. We came up with our first 43-101 resource and it came in a little over seven million ounces at 250 ounces a ton and that’s only silver. We did not do any silver equivalent. There’s also a lot of cobalt, copper, nickel and gold, but we calculated the resource purely for silver.

Our intent is probably to extend the program beyond the 50,000 meters to get to about 100,000 meters. We initiated all the environmental studies to put a ramp down. We do have a design for the ramp. The Camp is known for; we drill, we find, then we ramp, or we put down the shaft, and then we find even more by drilling underground. Our present resource is a little over seven million ounces, at an average grade of 250 ounces a ton, it's the highest grade mine anywhere in the world, by an order of magnitude.

Our next target will be about 30 million ounces in resources and we feel we will achieve it. Around us, within a little over a mile, over 70 million ounces were taken out of the ground at exceptional silver grades. It's a very simple project, a former producer, actually a brownfield site, but with a greenfield site discovery and so far, we've been very successful hitting these high grades. Some of these grades are in the order of magnitude of about 1,800 to 2,000 ounces a ton, but we went with an average grade of about 250 ounces a ton in our first resource estimate.

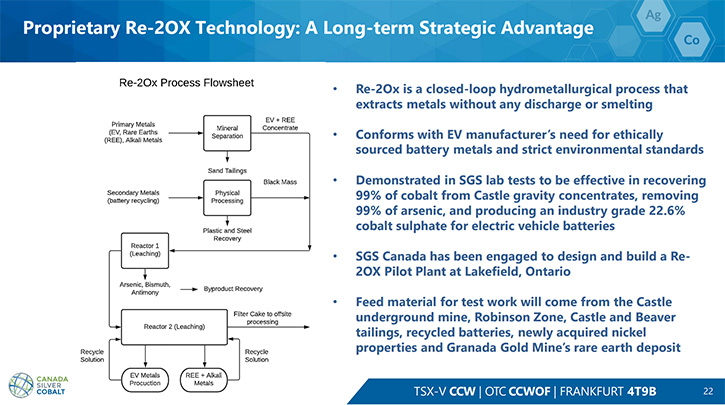

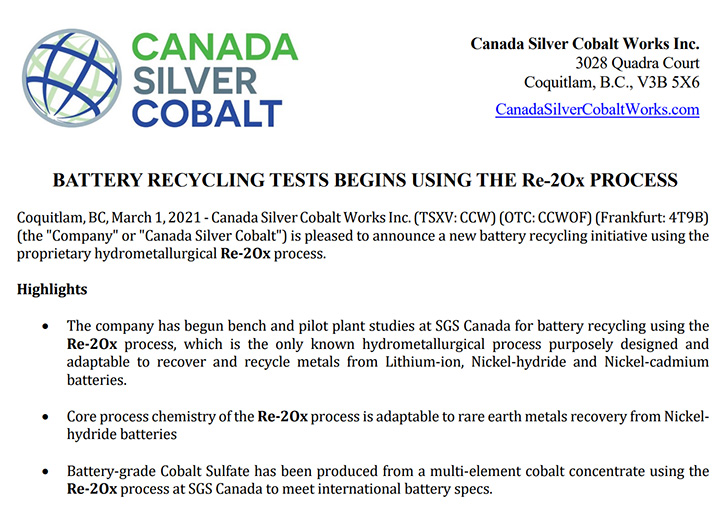

In addition to that, we have an extraction technology called the Re-2Ox process, and we've used that process to produce cobalt sulfate, which is one of the main metals in many batteries including the electric vehicle batteries. We produced that in 2018 and we're the only ones in the Cobalt camp that have been able to produce cobalt sulfate. In other words, we obtained the specs for cobalt sulphate, we produced it and we're able to use this process to produce a nickel sulfate for the battery market as well.

Dr. Allen Alper:

That's excellent. That market is booming, and it has great potential for electric vehicles. Can you say a few words about your process and also the electric vehicle market and the outlook for cobalt, nickel and silver?

Frank Basa:

The Cobalt Camp and a lot of the ore bodies have cobalt in them, also have what we call undesirables in them and the Re-2Ox process is a closed-loop, hydrometallurgical process that has the ability to remove the undesirables, mainly arsenic, without the use of a smelter. The process does work on the recycling of EV batteries, but we find the market for spent EV batteries challenging and I think it might be challenging for a little while because the majority of the spent or recycled batteries are going to smelters, which are very well established and are treating these used batteries. We are looking at that as well now, but we're being very realistic about it.

We're moving forward with our process. SGS is building a Re-2Ox pilot plant for us. Using that pilot plant, we intend to produce larger quantities of cobalt sulfate and nickel sulfate, for evaluation by end users. We also picked up another 40,000 hectares prospective in nickel, copper and cobalt mostly in Quebec. I think a lot of the battery manufacturers are having a difficult time getting cobalt and they’re actually switching it out with nickel. Nickel might end up being the main component in these lithium-ion batteries and I think that's the only way to be able to meet the future demand for metals from the battery market. There's not enough cobalt in the world to meet the upcoming demand for these lithium-ion batteries, so the manufacturers decrease the cobalt levels and increase the nickel levels and they still more or less get the same quality of product.

Dr. Allen Alper:

Sounds great. Could you tell our readers/investors a little bit about your background and your new President, Matt?

Frank Basa:

Yes, I am basically a metallurgical engineer, I focus on process development, I'm what I call a hydro-metallurgist. We've developed a few processes over the years, which have been commercialized. We've spent a fair amount of time in a Cobalt Camp and actually developed this process here over a six-year timeframe. Matt Halliday is part of our geological team, which we call the Dream Team. He's the first person in the Cobalt Camp who has found anything significant in the last 50 years. He's working with another geologist, Doug Robinson, and that's why we called it the Robinson Zone. We were able to find something successfully that nobody else has been able to find in the Cobalt Camp over many decades. These grades are what we call classical cobalt silver grades. The silver grades in the camp historically have been actually higher than 250 ounces a ton and some of them in the 2,000 plus ounces per ton. They're very narrow veins, but in some sections they are solid silver and that's why we have these very high grades.

Dr. Allen Alper:

That sounds excellent. Could you tell our readers/investors a little bit about your capital structure?

Frank Basa:

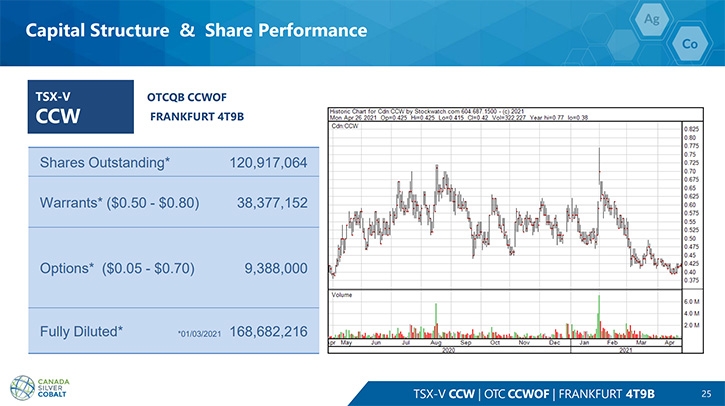

There's about 120 million shares outstanding, trading at 40 cents or thereabouts. We are down like everybody else. I call CCW a silver stock, I think it will focus on being a silver stock. We might end up separating the Company into two assets, one will be a silver stock and the next one will be a base metal EV play. I think that might be the best thing for our investors, we've done that before with another Company and then our investors get a dividend in a new Company. It seems to be a very good model, we are thinking of doing it again. We want our investors to benefit on two fronts, one being the silver market and the other being the electric vehicle market.

Dr. Allen Alper:

Sounds excellent! Could you tell our readers/investors the primary reasons they should consider investing in your Company?

Frank Basa:

Well, one of the main reasons is that we probably have the highest-grade silver deposit of anywhere in the world. Another thing is we also have a lot of cobalt. In addition, we have a process that we call Proof of Concept, which can produce cobalt sulfate on what we call Sumitomo specs, which are tough to meet. We've already poured a silver bar to show the world that we can pour a silver bar from the Castle mineralized material at our TTL facility. We also can recover the arsenic. And arsenic actually is one of the critical metals that the Americans have on their list of 40 critical metals.

Dr. Allen Alper:

Sounds like very strong reasons to consider investing in Canada Silver Cobalt Works. It looks like the silver market has a great forecast. Could you say a few words about that?

Frank Basa:

We have a lot of European investors and a few in the US and they're more confident in the increase in the price of silver than in the price of gold. They're coming in with these projections of over $50 dollars an ounce for silver and I think it might happen. It's happened in the past and I think it might happen again. Some of my investors, especially in the US, are feeling $80 dollars an ounce of silver is possible.

Dr. Allen Alper:

Well, it sounds like there's great demand for silver and silver has the two roles as a precious metal and also in electronics and technical uses, it's a critical metal.

Frank Basa:

They also use silver to build the high-end batteries.

Dr. Allen Alper:

Right. Is there anything else you'd like to add, Frank?

Frank Basa:

No, I think we’ve covered quite a bit of material here, I'm grateful you took the time.

Dr. Allen Alper:

I have enjoyed talking with you. We’ll publish your press releases as they come out, so our readers/investors can follow your progress.

https://canadasilvercobaltworks.com/

Frank J. Basa, P.Eng.

Chief Executive Officer

416-625-2342

|

|