CM Furnaces Exhibited at the 2014 PM World Congress to Demonstrate Versatile High-Temperature Furnaces and Technology

|

By Dr. Allen Alper

on 6/25/2014

Jim Neill, Vice President, spent some time with Dr. Alper at the recently held 2014 World PM Congress to discuss the history of the company and the variety of furnaces and services that CM Furnaces provides to customers.

In discussing the history of the company, Neill said, “CM Furnaces was started in 1946 by Seth Combs and James Murphy – that is where the CM comes from.” The company started in the refractory metals business, and quickly branched out into high temperature Hydrogen furnaces. He said, “At the beginning, we primarily made refractory metal components. Those components led us into the furnace business to shape and set these metal components. That then moved us into the greater refractory metal component business, selling furnaces to the lighting industry.”

CM Furnaces has always specialized in industrial furnaces and their associated parts. Neill said, “We have always been in high temperature furnaces, mostly hydrogen. Afterwards, we moved into oxidizing and inert atmosphere furnaces.” Working in this type of industry means that the company has specialized knowledge about high temperature furnaces. Said Neill, “The temperature range that we service is 1000 degrees Celsius to 2200 degrees Celsius.” The company also works with a variety of different types of gases for protective atmosphere. Neill said, “We work in hydrogen and hydrogen with nitrogen and argon. We also do air and inert.”

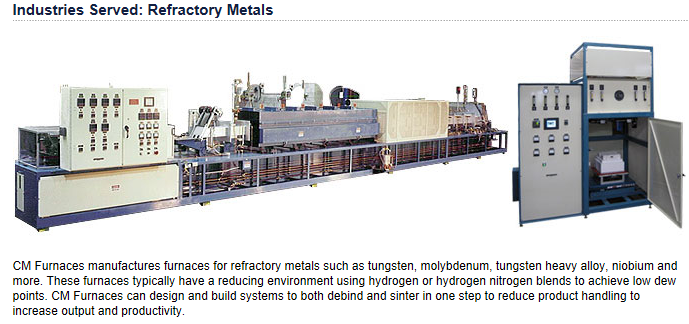

The furnaces developed by CM Furnaces are used for a myriad of different functions. Neill said, “The furnaces are used for sintering, annealing, co-firing, reduction and also general research and development.” There are other areas that the company works in as well. Neill said, “We still are in the refractory metal industry and, of course lighting, but we are also into glass, ceramics, fiber optics, powdered metallurgy, injection molding, ceramic injection molding, the wire industry, refractory products, the nuclear fuel industry, basic research and development and the national laboratories. Also, the university segment is a large portion of our business.”

Neill has been with the company for 30 years and now is running it with his brother. He said, “I joined CM in 1984. In 2000, my brother David and I purchased CM. CM has always been sold internally. We have been running the company ever since.” The two brothers have divided up the work of the company into the sales side and the production side. Said Neill, “I run the sales side of the business and David runs the production side.” Another notable figure in the furnace business is a part of the CM family. Neill said, “Don Whychell, FAPMI, joined us over 40 years ago. He heads up our research and development efforts. He has a complete laboratory with batch and continuous furnaces. He is working in two areas – new products and materials for our furnace construction.” In addition to working on research and development and products, Don Whychell also works directly with customers to help them optimize their furnace processes and other products. Said Neill, “Don also spends a lot of time working with customer’s processes to help them develop and size a furnace properly for production applications.”

As a privately held company, CM Furnaces has been able to carve out a niche of custom applications that have helped them to diversify their business. Said Neill, “Our company is privately held. One of the niches over the 68 years is that we have standard products, but we also build quite a few custom products. We are very good at that and we are very open to custom units.” CM’s team will work with customers to alter products to make sure that they work in an individual environment. Said Neill, “So, if someone comes with an application that is quite different or even a modification, we have the ability to tailor the furnace for that process.”

The company has been a regular attender of the PM Congress over the years and can see the value of exhibiting there. Said Neill, “This show has always been important to us, more so this year because we have three of our industries under one roof. We have refractory metals here, the powdered metal in terms of high-temperature sintering and the metal injection molding group, all of which we have serviced for many, many years and will continue to do so in the future.”

In terms of work load, the company is pretty evenly divided between standard products and complete custom furnace builds. Said Neill, “It varies from year to year, we build standard and custom furnaces about 50:50.” When customers approach them, the sales and engineering teams work hard to understand the needs of the customer. Said Neill, “The biggest thing we look for is what the customer needs versus what they want. If you tell us what you need, we can build it around your application.”

Neill believes that customers should choose them based on their expertise and experience in the high temperature furnace industry. He said, “We have been in high temperature longer than most. We also understand the significant weights and temperatures that go along with refractory metals. CM uses its own products. We understand the furnaces from the inside out.” Timing is also flexible, depending on the size of the project. Said Neill, “A small standard laboratory furnace has a lead time of as little as four weeks, a major custom furnace can be twenty-four weeks. Others might fit in the middle somewhere.”

CM Furnaces has become an important part of not only the industry, but their local community. Said Neill, “We are in a neighborhood. The town wants us to stay. They have worked with us through our many expansions. We are in Bloomfield, New Jersey. We are always interested in new applications and new challenges. We have a complete engineering staff to help with these challenges.”

For more information:

http://www.cmfurnaces.com

Phone 973 338 6500973 338 6500

|

|